Каталог Winstar фрезерование - страница 190

Навигация

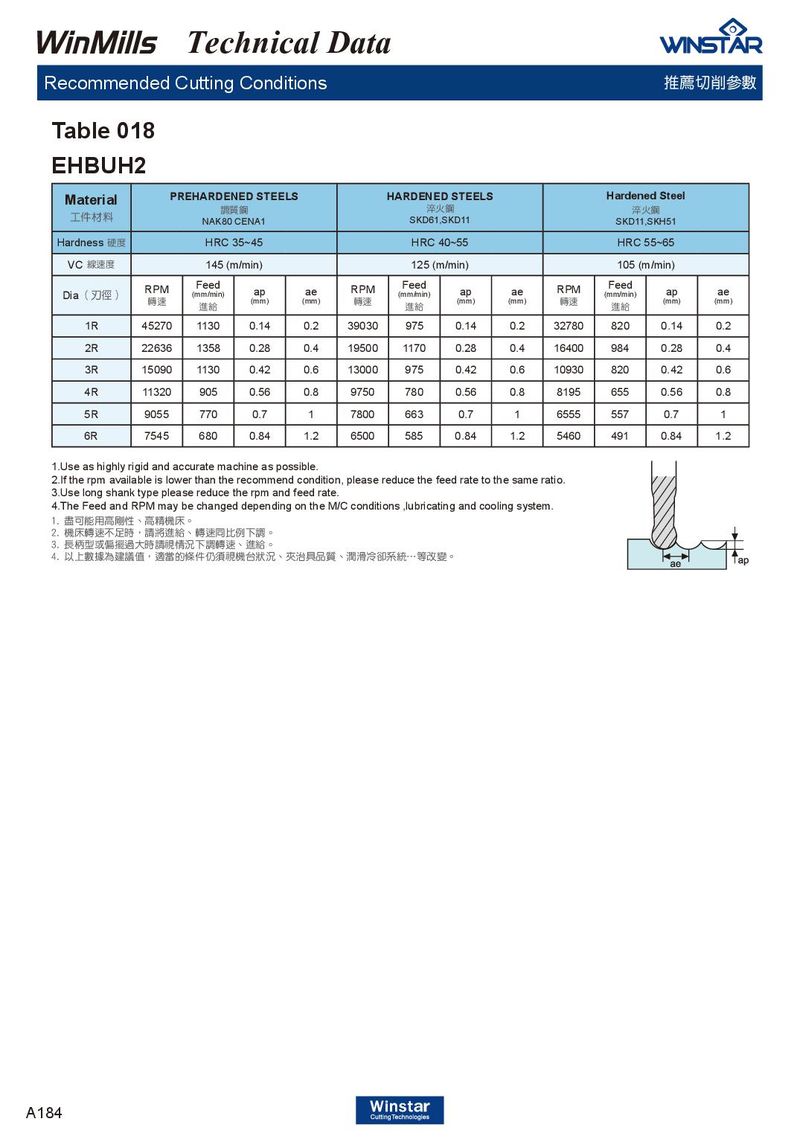

Technical Data Recommended Cutting Conditions 推薦切削參數 Table 018 EHBUH2 PREHARDENED STEELS HARDENED STEELS Hardened Steel Material 調質鋼 淬火鋼 淬火鋼 工件材料 NAK80 CENA1 SKD61,SKD11 SKD11,SKH51 Hardness 硬度 HRC 35~45 HRC 40~55 HRC 55~65 VC 線速度 145 (m/min) 125 (m/min) 105 (m/min) Feed Feed Feed RPM Dia ae RPM ( 刃徑 ) (mm/min) ap (mm/min) ap ae RPM (mm/min) ap ae 轉速 (mm) (mm) 轉速 (mm) (mm) 轉速 (mm) (mm) 進給 進給 進給 1R 45270 1130 0.14 0.2 39030 975 0.14 0.2 32780 820 0.14 0.2 2R 22636 1358 0.28 0.4 19500 1170 0.28 0.4 16400 984 0.28 0.4 3R 15090 1130 0.42 0.6 13000 975 0.42 0.6 10930 820 0.42 0.6 4R 11320 905 0.56 0.8 9750 780 0.56 0.8 8195 655 0.56 0.8 5R 9055 770 0.7 1 7800 663 0.7 1 6555 557 0.7 1 6R 7545 680 0.84 1.2 6500 585 0.84 1.2 5460 491 0.84 1.2 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. 1. 盡可能用高剛性、高精機床。 2. 機床轉速不足時,請將進給、轉速同比例下調。 3. 長柄型或偏擺過大時請視情況下調轉速、進給。 4. 以上數據為建議值,適當的條件仍須視機台狀況、夾治具品質、潤滑冷卻系統…等改變。 A184

Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar сверление

Каталог Winstar сверление Основной каталог Winstar 2021

Основной каталог Winstar 2021 Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020