Каталог Widia инструментальная оснастка - страница 537

Навигация

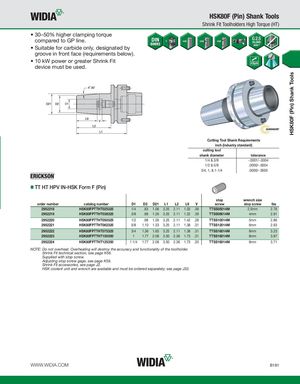

HSK80F (Pin) Shank Tools HSK80F (Pin) Shank Tools Shrink Fit Toolholders High Torque (HT) • 30–50% higher clamping torque compared to GP line. • Suitable for carbide only, designated by groove in front face (requirements below). • 10 kW power or greater Shrink Fit device must be used. D1 Cutting Tool Shank Requirements inch (industry standard) cutting tool shank diameter tolerance 1/4 & 3/8 -.0001/-.0004 1/2 & 5/8 .0000/-.0004 3/4, 1, & 1-1/4 .0000/-.0005 TT HT HPV IN-HSK Form F (Pin) stop wrench size order number catalog number D1 D2 D21 L1 L2 L9 V screw stop screw lbs 2952218 HSK80FPTTHT025325 1/4 .83 1.06 3.25 2.11 1.02 .39 TTSS05014M 2,5mm 2.76 2952219 HSK80FPTTHT038325 3/8 .98 1.26 3.25 2.11 1.22 .39 TTSS08014M 4mm 2.91 2952220 HSK80FPTTHT050325 1/2 .98 1.26 3.25 2.11 1.42 .28 TTSS10014M 5mm 2.86 2952221 HSK80FPTTHT062325 5/8 1.10 1.33 3.25 2.11 1.38 .31 TTSS12014M 6mm 2.93 2952222 HSK80FPTTHT075325 3/4 1.36 1.65 3.25 2.11 1.38 .31 TTSS16014M 8mm 3.23 2952223 HSK80FPTTHT100350 1 1.77 2.08 3.50 2.36 1.73 .31 TTSS16014M 8mm 3.97 2952224 HSK80FPTTHT125350 1 1/4 1.77 2.08 3.50 2.36 1.73 .20 TTSS16014M 8mm 3.71 NOTE: Do not overheat. Overheating will destroy the accuracy and functionality of the toolholder. Shrink Fit technical section, see page K56. Supplied with stop screw. Adjusting stop screw gage, see page K59. Shrink Fit accessories, see page J2. HSK coolant unit and wrench are available and must be ordered separately; see page J32. WWW.WIDIA.COM B181

Каталог Widia достижения 2021

Каталог Widia достижения 2021 Брошюра Widia решения для аэрокосмической промышленности

Брошюра Widia решения для аэрокосмической промышленности Брошюра Widia техническое руководство

Брошюра Widia техническое руководство Каталог Widia токарный инструмент 2020

Каталог Widia токарный инструмент 2020 Каталог Widia цельные концевые фрезы

Каталог Widia цельные концевые фрезы Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам