Каталог Widia инструментальная оснастка - страница 1098

Навигация

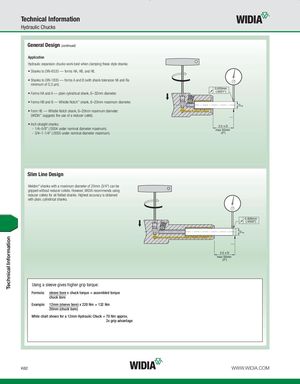

Technical Information Hydraulic Chucks General Design (continued) Application Hydraulic expansion chucks work best when clamping these style shanks: • Shanks to DIN-6535 — forms HA, HB, and HE. • Shanks to DIN-1835 — forms A and B (with shank tolerance h6 and Ra minimum of 0,3 μm). 0,003mm • Forms HA and A — plain cylindrical shank, 6–32mm diameter. (.0001") • Forms HB and B — Whistle Notch™ shank, 6–20mm maximum diameter. D h6 • Form HE — Whistle Notch shank, 6–20mm maximum diameter. (WIDIA™ suggests the use of a reducer collet). • Inch straight shanks: 2.5 x D - 1/4–5/8" (.0004 under nominal diameter maximum). max 50mm - 3/4–1-1/4" (.0005 under nominal diameter maximum). (2") Slim Line Design Weldon® shanks with a maximum diameter of 20mm (3/4") can be gripped without reducer collets. However, WIDIA recommends using reducer collets for all flatted shanks. Highest accuracy is obtained with plain, cylindrical shanks. 0,006mm (.0002") D h6 2.5 x D max 50mm (2") Using a sleeve gives higher grip torque: Formula: sleeve bore x chuck torque = assembled torque chuck bore Example: 12mm (sleeve bore) x 220 Nm = 132 Nm 20mm (chuck bore) While chart shows for a 12mm Hydraulic Chuck = 70 Nm approx. 2x grip advantage K62 WWW.WIDIA.COM Technical Information

Каталог Widia достижения 2021

Каталог Widia достижения 2021 Брошюра Widia решения для аэрокосмической промышленности

Брошюра Widia решения для аэрокосмической промышленности Брошюра Widia техническое руководство

Брошюра Widia техническое руководство Каталог Widia токарный инструмент 2020

Каталог Widia токарный инструмент 2020 Каталог Widia цельные концевые фрезы

Каталог Widia цельные концевые фрезы Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам