Каталог NIKON iNEXIV VMA на английском - страница 3

Навигация

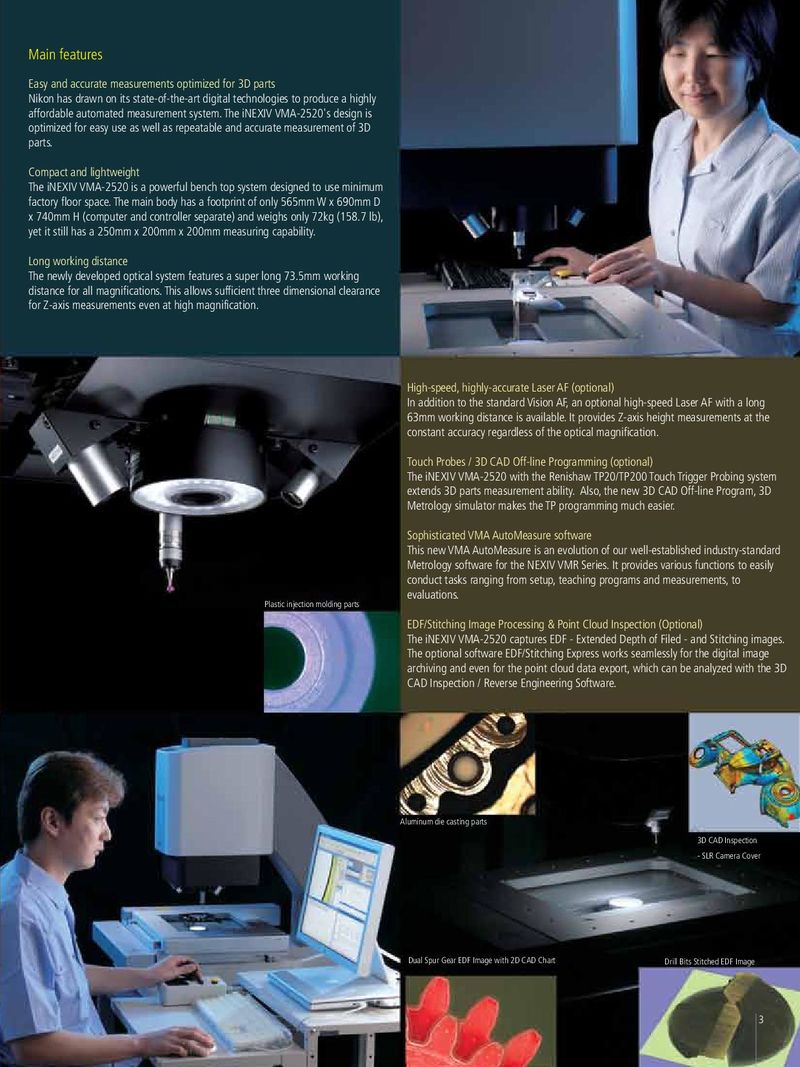

Main features Easy and accurate measurements optimized for 3D parts Nikon has drawn on its state-of-the-art digital technologies to produce a highly affordable automated measurement system. The iNEXIV VMA-2520's design is optimized for easy use as well as repeatable and accurate measurement of 3D parts. Compact and lightweight The iNEXIV VMA-2520 is a powerful bench top system designed to use minimum factory floor space. The main body has a footprint of only 565mm W x 690mm D x 740mm H (computer and controller separate) and weighs only 72kg (158.7 lb), yet it still has a 250mm x 200mm x 200mm measuring capability. Long working distance The newly developed optical system features a super long 73.5mm working distance for all magnifications. This allows sufficient three dimensional clearance for Z-axis measurements even at high magnification. High-speed, highly-accurate Laser AF (optional) In addition to the standard Vision AF, an optional high-speed Laser AF with a long 63mm working distance is available. It provides Z-axis height measurements at the constant accuracy regardless of the optical magnification. Touch Probes / 3D CAD Off-line Programming (optional) The iNEXIV VMA-2520 with the Renishaw TP20/TP200 Touch Trigger Probing system extends 3D parts measurement ability. Also, the new 3D CAD Off-line Program, 3D Metrology simulator makes the TP programming much easier. Sophisticated VMA AutoMeasure software This new VMA AutoMeasure is an evolution of our well-established industry-standard Metrology software for the NEXIV VMR Series. It provides various functions to easily conduct tasks ranging from setup, teaching programs and measurements, to Plastic injection molding parts evaluations. EDF/Stitching Image Processing & Point Cloud Inspection (Optional) The iNEXIV VMA-2520 captures EDF - Extended Depth of Filed - and Stitching images. The optional software EDF/Stitching Express works seamlessly for the digital image archiving and even for the point cloud data export, which can be analyzed with the 3D CAD Inspection / Reverse Engineering Software. Aluminum die casting parts 3D CAD Inspection - SLR Camera Cover Dual Spur Gear EDF Image with 2D CAD Chart Drill Bits Stitched EDF Image 3

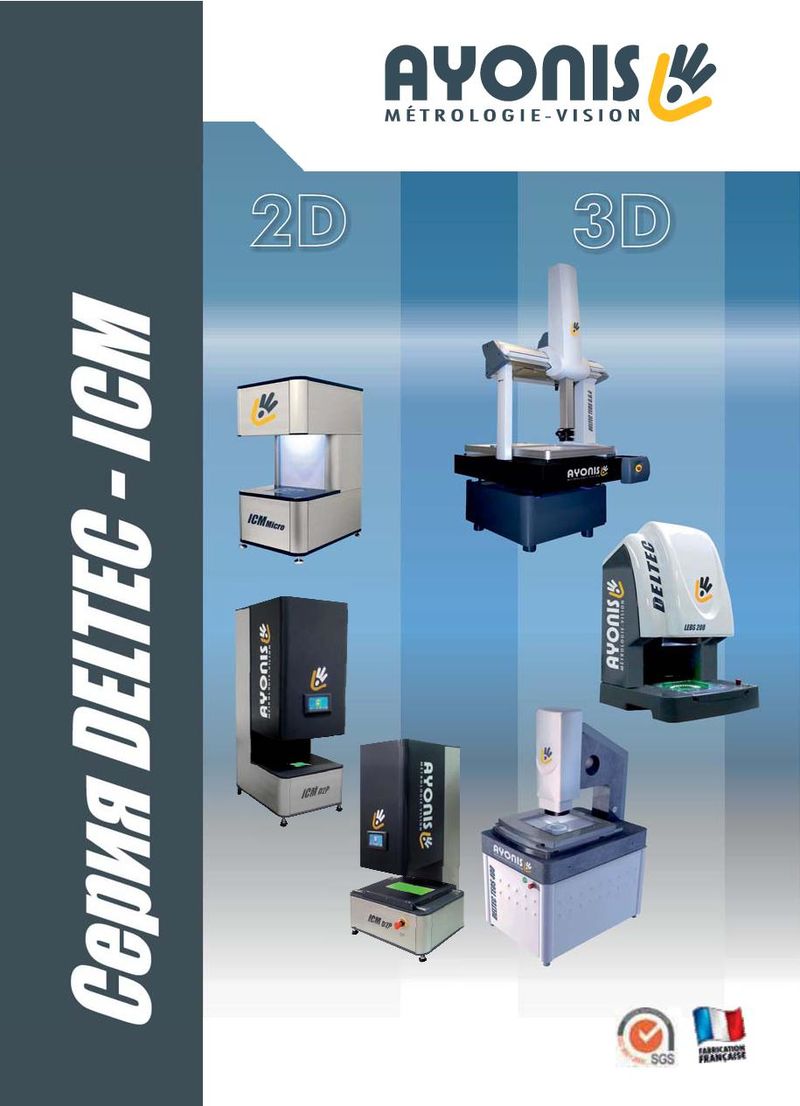

Каталог Ayonis Deltec

Каталог Ayonis Deltec Каталог NIKON iNEXIV VMA

Каталог NIKON iNEXIV VMA