Каталог TooTool техническая информация 2 - страница 54

Навигация

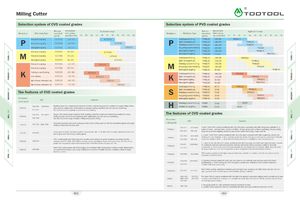

Milling Cutter A\ Selection system of CVD coated grades Selection system of PVD coated grades Recom- Recommen- Application range Recom- Recommen- Application range Workpiece Machning Type mended ded cutting Workpiece Machning Type mended ded cutting grade speed(m/min) 01 05 10 15 20 25 30 35 40 45 50 grade speed(m/min) 01 05 10 15 20 25 30 35 40 45 50 Medium to roughing TCP9330 120-290 TCP9330 Continuous finishing TPM8115 150-280 TPM8115 P Medium to roughing TCP9340 130-330 TCP9340 light interrupted cuts. TPM8125 180-360 TPM8125Finishing to semi-finsihingTPM8225180-290TPM8225 Interrupted roughing TCP9350 100-270 TCP9350 Roughing to semi-finishing TPG4235 105-185 TPG4235 Medium to roughing TCP9330 80-200 TCP9330 Interrupted roughing TPM8135 100-150 TPM8135 M Medium to roughing TCP9340 90-220 TCP9340 Interrupted roughing TPK4235H 75-135 TPK4235HContinuous finishingTPM8115150-250TPM8115 Interrupted roughing TCP9350 80-100 TCP9350 light interrupted cuts. TPM8125 110-270 TPM8125 Medium to roughing TCP9330 110-270 TCP9330Medium to roughingTCP934080-250TCP9340 M Finishing to semi-finsihing TPM8225Roughing to semi-finsihingTPG4235120-240100-230 TPM8225TPG4235Interrupted roughingTPM813580-100TPM8135 K Finishing to semi-finishingsemi-finishingTCK5305 200-480TCK5315130-310 TCK 5305 TCK 5315light to heavy interrupted cuts.TCK5325140-230TCK5325 Continuous finishing TPM8115 140-230 TPM8115Klight interrupted cuts.Interrupted roghingTPM8125110-180TPM813585-160TPM8125TPM8135 Interrupted roghing TPK4235H 85-160 TPK4235H light to heavy interrupted cuts. TCK 5335 110-160 TCK5335 Continuous finishing TPM8115 40-70 TPM8115 The features of CVD coated grades s light interrupted cuts. TPM8125Finishing to semi-finsihingTPM822520-6030-60 TPM8125TPM8225 Roughing to semi-finsihing TPG4235 30-60 TPG4235 Recomme- Interrupted roughing TPM8135 30-50 TPM8135 ISO Features nded grade P20-P30 M20-M30 Medium hard CVD-coated grade (medium to thick coating) designed for medium to rough milling of lowTCP9330alloy steel & unalloy steel, applications in average cutting conditions for wet and dry machining.HFinishing to semi-finsihingHX200Medium to roughingHX40035-6535-50HX200HX400 K15 - K 25 The first choice for roughing to semi-finish face milling. P30-P40 M25-M35 Tough CVD-coated grade (medium thick coating) suited for tough and demanding medium to rough The features of CVD coated grades TCP9340 milling of steel, cast iron and hardened steel, applications for wet and dry machining. K 25 - K 30 The first choice for rough shoulder milling and groove milling. Recomme- ISO Features Toughest substrate with hard coating provides stable cutting and tool life for severeinterrupted and rough nded grade TCP9350 P35- P 50 M 30- M40 milling of steel and stainless steel. P01-P15 M10-M20 2-4pm TiALN PVD coating combined with ultra fine grain substrates with high-toughness suitable for a TPM8115 variety of steel , stainless steel, cast iron & HRSA at high speed and continue machining. Strong cutting TCK5315 K10-K25 Thigh wear-resistant substrates perfect combine with MT-TiCN, thick AI203 coating, ideal for ductile castiron & grey cast iron at high cutting speed.CVD-coated grade with high edge line security, wear-resistant & good toughness substrates perfectK05 - K15S05 - S15edge and excellent chipping resistance guarantees stable machining, longer tool lifeTPM8125P15 - P35M15-M351. 2-4pm TiALN PVD coating combined with ultra fine grain substrate with high toughness suitable forfinishing to semi-finishing. 2. Basic material grade for milling steel parts and easy to cut/medium difficultyK15 - K 35S15 - S30to process stainless steel.3. High theraml shock resistance is suitable for light interrupted cut. TCK5325 K20-K35 combine with MT-TiCN, thick AI203 coating, suitable for light to heavy interrupted cuts, the first choice grades for roughing 8L high metal removal rate of ductile cast iron & grey cast iron.Hard CVD-coated grade with thick coating can withstand high temperatures without plastic deformation,TCK5335K30-K40are used for finishing to light rough milling of all cast iron in stable and wet conditions. Ideal for large1. 2-4pm AlCrN+AICrSiN PVD coating combined with ultra fine grain substrates with high-toughness suitableTPM8225P10-P3M20-M40for martenstic stainless steel and austenitic stainless steel under difiicult working conditions and highS15 - S25temperature. 2. Used as the preferred material grade for machining high temperature alloys under unstableworking conditions.3.It is recommended to process tempered steel and nickel-based material. diameter cutters. TPM8135 P20-P40 M25 - M40 PVD coating combined with high-resistant substrates, suitable for stainless steel 8L low carbon steel inroughing to semi-finishing. P20-P40 M20-M40 1. Superior universal grade for steel, cast iron, hard-to-cut materials and stainless steel with stable TPG4235 machinability .2. New coating and ultra fine grain provide wear resistance and oxidation resistance. S20-S40 3.TiALN+TiN series new coatig. TiALN thick coating, optimized material grade for high wear resistance of milled steel and cast iron. It is TPK4235H P35 - P45 K 25 - K 35 also a general choice for low speed and unstable cutting conditions H10-H20 P25 - P35 The latest TiALN coating combined with the ultra-fine grained cemented carbide matrix provide good wear HX200 M15 - M35 K15 - K 25 resistance and oxidation resistance.It is suitable for hardended steel below HRC58, cast iron and stainless S10-S20 steel at high speed milling. 1. Roughing grade for high hardened steel and pressed die steel . HX400 H05 -H15 2. Excellent wear resistance ideal for machining die steel and high hardened steel over HRC50 463 464

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы