Каталог TooTool техническая информация 2 - страница 181

Навигация

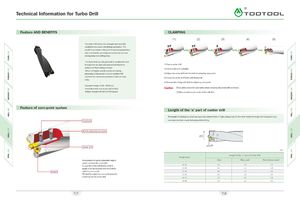

Technical Information for Turbo Drill A\ Feature AND BENEFITS CLAMPING The turbo drill delivers the strength and versatilityVneeded for any deep hole drilling application.Theexcellent geometry is designed to increase penetrationrates and tool life,providing the lowest cost per holeamong deep hole drilling lines.•The Turbo Drill uses the pilot drill to stabilize the toolthrough the cut,and outboard carbide inserts toachieve the final cutting diameter•Allows for higher spindle speeds and takingadvantage of the power curve on modern CNC(D(2)igo*(3)(4)- —(5)K1) Place a center drill.2) Clamp insert and . cartridge3) Adjust the center drill with the bolt for adjusting cone . point machines for maximum penetration rates on deepholes. 4) Clamp the center drill firmly with fixing bolt. 5) Reassure the clamp with bolt for adjusting cone point. •Diameter Range: 25.00 - 80.00mm. •Available in 4xD,SxD,6.5xD,8xD & 10xD Caution ®Use safety covers for your safety when clamping the center drill and insert. •Utilizes Standard WCMX & SPMG Inserts ©When machining,be careful of the drill disk Feature of corn-point system Length of the ‘a’ part of center drill The length of'a'being too short can cause bad surface finish or high cutting load.On the other hand, the length of'a'being too long -| Fixed bolt | can make tool failure and chattering while drilling. j Bolt for adjusting cone point ] ( a. sS ( j Center drill | mm i Length of the "a" part of center drill Designation •Convenient and quick adjustable heights Steel Alloy steel Non-ferrous metal when inserting the center drill. •In case the centerdrill brakes while in 25-30 1.2 1.0 1.5 usage,it can be replaced with the bolt for 31-40 1.5 1.3 1.8 j Insert adjusting cone point. 41- 50 1.8 1.5 2.2 •The bolt for adjusting cone point prevents 51- 59 2.2 1.8 2.5 chattering on the centerdrill. 60-75 2.5 2.0 2.8 76-80 3.0 2.5 3.5 717 718

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы