Каталог TooTool техническая информация 2 - страница 163

Навигация

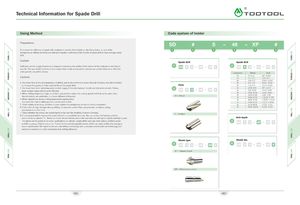

Technical Information for Spade Drill A\ Using Method Code system of holder Preparations B fA To increase the effciency of spade drill, workpieces must be fixed tightly on the fixing frame, in case of the workpieces or drilling machines are with poor rigidity, it will reduce the tool life of spade drill or even damage spade drill.Coolant Spade Drill _ Spade Drill Sufficient coolant supply & pressure is required to increase the quality of the surface of the workpieces and extendtool life. The size ofsolid particles in the coolant fluid should not exceed to micron use coolant filtration to filter the O E2 Q E ED ~ EDQ © EDDO - ED - ESQ solid particles exceed to micron. Connector Metric Inch Cautions YO 9.5-11.0 3/8’•-27/64"zo11.5-12.57/16" - l/2" 00 13.0-17-5 33/64"-ll/16" 1. Use lower feed at the very beginning of drilling and at the moment of going through the holes, this will be hlepful 05 15.5-17.5 39/64"-ll/16" to increase the quality of holes and tool life of the spade drills. Flute 10 17.6-24.4 11/16"-15/16" 2. Use lower feed when adopting outer coolant supply, if the ratio between length and diameter exceeds 3 times,inner coolant supply will be quite effective. © E2 Q E - GD - E E Q 15 22.00-24.4 7/8"-15/16"2024.5-35.0015/16"-13/8" 3. When drilling roughness, slope, cross hole, you need to reduce the cutting speed and feed, at the same time, 25 30.00-35.00 13/16"-13/8" shorter holders are preferable, or choose different drill points. H = Helical 30 35.10-47.90 13/8"-17/8"3542.00-47.901 21/32"-!7/8" 4. When chamfering, reduce cutting parameters appropriately 40 48.00-65.28 1 29/32"-2 9/16" and avoid the chip-breaking grooves cut workpieces first. 45 56.00-65.28 2 7/32"-2 9/16" 5. If the rigidity of working condition is poor, tighten the workpieces or reduce cutting parameters. 50 65.30-89.08 2 7/32"-3 1/2" 6. If the color of chips changes during drilling, increase the coolant fluid and pressure, or reduce cutting 70 89.10-114.48 3 l/32"-4 1/2" parameters to be less heat. 7. Check whether the screws are locked tightly to be sure the reliability of insert clamping.. 8. It is recommended to replace the insert before it is completely worn insert can be re-grinded. 9 Better to choose shorter holder, ensure out, this can protect the holders, and the the machines are with good rigidity and high power.The above are the points to be noed, applications on jobsites usually differ, you may meet various problem abouttool life, accuracy of holes and so on. Thanks for the interchangeable inserts, which can solve problem by changingS = StraightDrill depth© S3 Q QEDC23 D inserts and holders. We expect to discuss hole drilling technology wtih customers and provide our technology and service to customers in order to increase hole drilling efficiency. Shank type© Q33 Q B ~ E0EH3 Q Shank dia.© EEQE - GD “ EEO XP = Flanged shank MT = Morse taper shank 681 682

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы