Общий каталог Sumitomo 2019 - 2020 - страница 815

Навигация

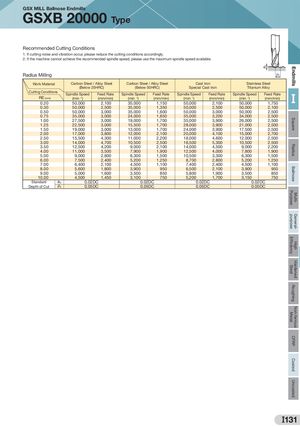

ap UncoatedCoatedCFRPNon-ferrousMetalRoughingHardenedSteelHighEfficiencyGeneral-purposeMulti-PurposeBallnoseRadiusSquareEndmills GSX MILL Ballnose Endmills GSXB 20000 Type Recommended Cutting Conditions 1. If cutting noise and vibration occur, please reduce the cutting conditions accordingly. 2. If the machine cannot achieve the recommended spindle speed, please use the maximum spindle speed available. Radius Milling pf Work Material Carbon Steel / Alloy Steel Carbon Steel / Alloy Steel Cast Iron Stainless Steel (Below 25HRC) (Below 50HRC) Special Cast Iron Titanium Alloy Cutting Conditions Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed RateRE (mm)(min -1)(mm/min)(min -1)(mm/min)(min -1)(mm/min)(min -1)(mm/min)0.2050,0002,10035,0001,15050,0002,10050,0001,750I 0.30 50,000 2,500 35,000 1,350 50,000 2,500 50,000 2,100 0.50 50,000 3,000 35,000 1,600 50,000 3,000 50,000 2,500 0.75 35,000 3,000 24,000 1,650 35,000 3,200 34,000 2,500 1.00 27,500 3,000 19,000 1,700 35,000 3,900 26,000 2,500 1.25 22,500 3,000 15,500 1,700 28,000 3,900 21,000 2,500 1.50 19,000 3,000 13,000 1,700 24,000 3,900 17,500 2,500 2.00 17,000 3,800 12,000 2,100 20,000 4,100 15,000 2,700 2.50 15,500 4,300 11,000 2,200 18,000 4,600 12,000 2,500 3.00 14,000 4,700 10,500 2,500 16,500 5,300 10,500 2,500 3.50 12,500 4,200 9,000 2,100 14,000 4,500 9,000 2,200 4.00 11,000 3,500 7,900 1,900 12,500 4,000 7,800 1,900 5.00 9,000 2,800 6,300 1,500 10,500 3,300 6,300 1,500 6.00 7,500 2,400 5,200 1,250 8,700 2,800 5,200 1,250 7.00 6,400 2,100 4,500 1,100 7,400 2,400 4,500 1,100 8.00 5,600 1,800 3,900 950 6,500 2,100 3,900 950 9.00 5,000 1,600 3,500 850 5,800 1,900 3,500 850 10.00 4,500 1,450 3,100 750 5,200 1,700 3,150 750 Standard ap 0.02DC 0.02DC 0.02DC 0.02DC Depth of Cut pf 0.05DC 0.05DC 0.05DC 0.05DC I131

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019