Общий каталог Sumitomo 2019 - 2020 - страница 774

Навигация

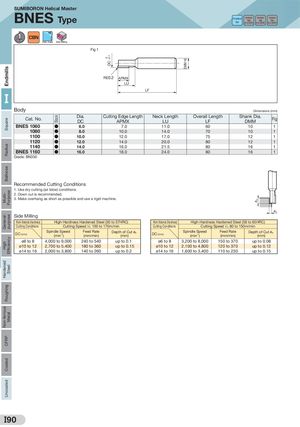

EndmillsSquareRadiusBallnoseMulti-PurposeGeneral-purposeHighEfficiencyHardene dSteelRoughingNon-ferrousMetalCFRPCoatedUncoated Stock 0 DC -0.1 DMM h6 ap SUMIBORON Helical Master BNES Type Pre-hardenedSteelHardenedSteel45 to 55HRCHardenedSteel55 to 60HRCHardenedSteel60 to 65HRC Flute Helix Angle Side Milling Fig 1 RE0.2 APMX LU LF I Body Dimensions (mm) Cat. No. Dia.DC Cutting Edge Length Neck Length Overall LengthAPMXLULF Shank Dia.DMM Fig BNES 1060 ● 6.0 7.0 11.0 60 10 1 BNES 1080 ● 8.0 10.0 14.0 70 10 1 BNES 1100 ● 10.0 12.0 17.0 75 12 1 BNES 1120 ● 12.0 14.0 20.0 80 12 1 BNES 1140 ● 14.0 16.0 21.5 80 16 1 BNES 1160 ● 16.0 18.0 24.0 80 16 1 Grade: BN350 Recommended Cutting Conditions 1. Use dry cutting (air blow) conditions. 2. Down cut is recommended. 3. Make overhang as short as possible and use a rigid machine. ae Side Milling Work Material (Hardness) High-Hardness Hardened Steel (50 to 57HRC) Work Material (Hardness) High-Hardness Hardened Steel (58 to 65HRC) Cutting Conditions Cutting Speed VC 100 to 170m/min Cutting Conditions Cutting Speed VC 80 to 150m/min DC (mm) Spindle Speed Feed Rate Depth of Cut ae(min-1)(mm/min)(mm)DC (mm) Spindle Speed Feed Rate Depth of Cut ae(min-1)(mm/min)(mm) ø6 to 8 4,000 to 9,000 240 to 540 up to 0.1 ø6 to 8 3,200 to 8,000 150 to 370 up to 0.08 ø10 to 12 2,700 to 5,400 180 to 360 up to 0.15 ø10 to 12 2,100 to 4,800 120 to 370 up to 0.12 ø14 to 16 2,000 to 3,800 140 to 260 up to 0.2 ø14 to 16 1,600 to 3,400 110 to 230 up to 0.15 I90

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019