Общий каталог Sumitomo 2019 - 2020 - страница 545

Навигация

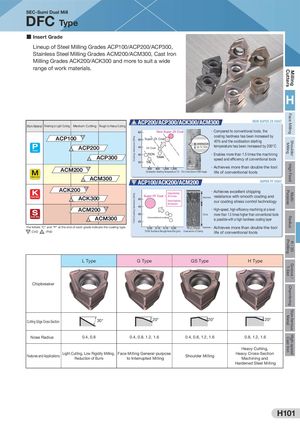

Coating Hardness (GPa)TiCN Coating Hardness (GPa) High-speedCast IronNon-ferrousMetalChamferingGroove /T-SlotR / 3DProfilingRadiusMulti-PurposeHigh FeedShoulderMillingFace MillingMillingCutters SEC-Sumi Dual Mill DFC Type ■ Insert Grade Lineup of Steel Milling Grades ACP100/ACP200/ACP300, Stainless Steel Milling Grades ACM200/ACM300, Cast Iron Milling Grades ACK200/ACK300 and more to suit a wide range of work materials. H Work Material Finishing to Light Cutting Medium Cutting Rough to Heavy Cutting New Super ZX Coat · Compared to conventional tools, the ACP100 C coating hardness has been increased bySuper ZX Coat40% and the oxidisation starting Laminating Cycle Steel P ACP200 ZX Coat Up To 10nm temperature has been increased by 200°C · Enables more than 1.5 times the machining P ACP300 speed and efficiency of conventional tools ACM200 C 10nm · Achieves more than double the toolOxidisation Starting Temperature (°C)Film Cross-Section (TEM Image)life of conventional tools Stainless Steel P ACM300 ACK200 C Coating Hardness: · Achieves excellent chipping Cast Iron P ACK300 Super FF Coat 30% Increase Alumina resistance with smooth coating andSurface Roughness:our coating stress control technology 50% Reduction ACM200 C · High-speed, high-efficiency machining at a level TiCN more than 1.5 times higher than conventional tools Exotic Alloy P ACM300 Conventional coating is possible with a high hardness coating layer The letters "C" and "P" at the end of each grade indicate the coating type. Substrate · Achieves more than double the tool C : CVD P : PVD TiCN Surface Roughness Ra (μm) Cross-section of Coating life of conventional tools L Type G Type GS Type H Type Chipbreaker Cutting Edge Cross Section 30° 20° 20° 20° Nose Radius 0.4, 0.8 0.4, 0.8, 1.2, 1.6 0.4, 0.8, 1.2, 1.6 0.8, 1.2, 1.6 Heavy Cutting, Features and Applications Light Cutting, Low Rigidity Milling,Reduction of BurrsFace Milling General-purposeto Interrupted Milling Shoulder Milling Heavy Cross-SectionMachining and Hardened Steel Milling H101

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019