Общий каталог Sumitomo 2019 - 2020 - страница 544

Навигация

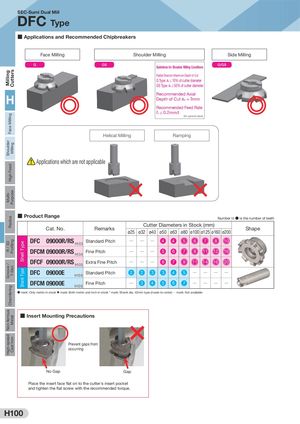

Milling CuttersFace MillingShoulde rMillingHigh FeedMulti-PurposeRadiusR / 3DProfilingGroove /T-SlotChamferingNon-ferrousMetalHigh-speedCast Iron Shell TypeShank Type SEC-Sumi Dual Mill DFC Type ■ Applications and Recommended Chipbreakers Face Milling Shoulder Milling Side Milling G GS Guidelines for Shoulder Milling Conditions G/GS Radial Direction Maximum Depth of Cut G Type: ae ≤ 10% of cutter diameter GS Type: ae ≤ 50% of cutter diameter Recommended Axial H ◎ ◎ Depth of Cut ap = 3mmRecommended Feed Ratefz ≤ 0.2mm/t ◎ (for general steel) Helical Milling Ramping Applications which are not applicable × × ■ Product Range Number in ● is the number of teeth Cutter Diameters in Stock (mm) Cat. No. Remarks ø25 ø32 ø40 ø50 ø63 ø80 ø100 ø125 ø160 ø200 Shape DFC 09000R/RS H103 Standard Pitch Q Q Q 4 4 5 6 7 8 10 DFCM 09000R/RS H104 Fine Pitch Q Q Q 5 6 7 8 11 12 16 DFCF 09000R/RS H105 Extra Fine Pitch Q Q Q 6 7 9 11 14 16 20 * * * DFC 09000E H106 Standard Pitch 2 2 3 3 4 5 Q Q Q Q * * * DFCM 09000E H106 Fine Pitch Q 3 4 5 6 7 Q Q Q Q D mark: Only metric in stock A mark: Both metric and inch in stock * mark: Shank dia. 42mm type (made-to-order) Q mark: Not available ■ Insert Mounting Precautions ○ × Prevent gaps from occurring No Gap Gap Place the insert face at on to the cutter's insert pocket and tighten the at screw with the recommended torque. H100

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019