Общий каталог Sumitomo 2019 - 2020 - страница 517

Навигация

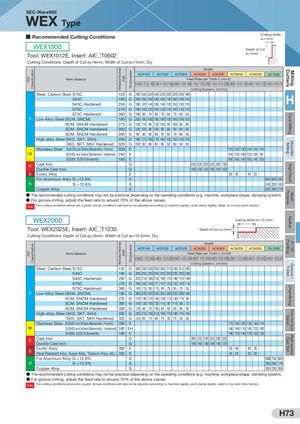

ISOISO cationClassicationClassi Workpiece HardnessWorkpiece Hardness (HB)(HB) ChipbreakerChipbreaker High-speedCast IronNon-ferrousMetalChamferingGroove /T-SlotR / 3DProfilingRadiusMulti-PurposeHigh FeedShoulderMillingFace MillingMillingCutters SEC-WaveMill WEX Type ■ Recommended Cutting Conditions Cutting Widthae=1mm WEX1000 Depth of Cut Tool: WEX1012E, Insert: AX□T0602 ap=4mm Cutting Conditions: Depth of Cut ap=4mm, Width of Cut ae=1mm, Dry Grade ACP100 ACP200 ACP300 ACK200 ACK300 ACM200 ACM300 DL1000 Work Material Feed Rate per Tooth fz (mm/t) 0.08 0.12 0.16 0.08 0.12 0.16 0.08 0.12 0.16 0.10 0.15 0.20 0.10 0.15 0.20 0.08 0.10 0.12 0.08 0.10 0.12 0.05 0.10 0.15 Cutting Speed vc (m/min) Steel, Carbon Steel S15C 125 G 260 240 220 240 220 200 220 200 180 S45C 190 G 200 180 160 180 160 140 180 160 140S45C Hardened250G180 120 140 160 140 120 150 130 110 H S75C 270 G 160 140 120 150 130 110 130 110 110 S75C Hardened 300 G 100 80 70 90 70 60 70 60 50 P Low Alloy Steel (SCM, SNCM) 180 G 200 180 160 180 160 150 160 150 130 SCM, SNCM Hardened 275 G 130 110 90 120 100 90 100 90 80 SCM, SNCM Hardened 300 G 120 100 80 100 90 80 90 80 60 SCM, SNCM Hardened 350 G 90 80 60 80 70 60 70 60 40 High-alloy Steel (SKD, SKT, SKH) 200 G 180 170 160 170 160 130 150 140 120 SKD, SKT, SKH Hardened 325 G 100 80 60 80 60 50 60 50 30 Stainless Steel SUS430 and Others (Martensitic / Ferritic) 200 E 170 150 120 140 130 110 M SUS403 and others (Martensitic / Hardened) 240 E 140 120 100 120 100 90 SUS304, SUS316 (Austenitic) 180 E 180 160 140 160 140 130 K Cast Iron G 240 220 200 220 200 180 Ductile Cast Iron G 160 140 120 140 120 100 S Exotic Alloy E 50 35 45 25 For Aluminum Alloy Si ≤12.6% S 800 600 400 N Si >12.6% S 240 200 160 Copper Alloy S 330 300 270 ● The recommended cutting conditions may not be practical depending on the operating conditions (e.g. machine, workpiece shape, clamping system). ● For groove milling, adjust the feed rate to around 70% of the above values. Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to machine rigidity, work clamp rigidity, depth of cut and other factors. WEX2000 Cutting Width ae=12.5mm Tool: WEX2025E, Insert: AX□T1235 Depth of Cut ap=3mm Cutting Conditions: Depth of Cut ap=3mm, Width of Cut ae=12.5mm, Dry Grade ACP100 ACP200 ACP300 ACK200 ACK300 ACM200 ACM300 DL1000 Work Material Feed Rate per Tooth fz (mm/t) 0.08 0.15 0.20 0.08 0.15 0.20 0.08 0.15 0.20 0.08 0.15 0.20 0.08 0.15 0.20 0.08 0.15 0.20 0.08 0.15 0.20 0.05 0.15 0.22 Cutting Speed vc (m/min) Steel, Carbon Steel S15C 125 G 380 350 330 350 330 315 330 315 295 S45C 190 G 285 255 235 255 235 220 235 220 200 S45C Hardened 250 G 235 210 190 210 190 170 190 170 150 S75C 270 G 190 162 143 171 152 133 152 133 115 S75C Hardened 300 G 145 115 95 115 95 75 95 75 55 P Low Alloy Steel (SCM, SNCM) 180 G 265 235 220 235 220 200 220 200 180 SCM, SNCM Hardened 275 G 170 145 125 150 130 115 130 115 95 SCM, SNCM Hardened 300 G 150 125 105 135 115 95 115 95 75 SCM, SNCM Hardened 350 G 125 95 75 105 85 65 85 65 45 High-alloy Steel (SKD, SKT, SKH) 200 G 235 210 190 210 190 170 190 170 150 SKD, SKT, SKH Hardened 325 G 125 95 75 95 75 55 75 55 35 Stainless Steel SUS430 and Others (Martensitic / Ferritic) 200 E 175 155 125 155 140 110 M SUS403 and others (Martensitic / Hardened) 240 EH 160 140 110 145 125 100 SUS304, SUS316 (Austenitic) 180 E 190 170 140 170 150 125 K Cast Iron G 285 255 235 255 235 220 Ductile Cast Iron G 190 160 140 160 140 125 S Exotic Alloy 300(Heat-Resistant Alloy, Super Alloy, Titanium Alloy, etc.)330EE 50 40 45 3535253020 For Aluminum Alloy Si ≤12.6% S 1000 750 500 N Si >12.6% S 250 200 170 Copper Alloy S 350 330 300 ● The recommended cutting conditions may not be practical depending on the operating conditions (e.g. machine, workpiece shape, clamping system). ● For groove milling, adjust the feed rate to around 70% of the above values. Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to machine rigidity, work clamp rigidity, depth of cut and other factors. H73

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019