Общий каталог Sumitomo 2019 - 2020 - страница 418

Навигация

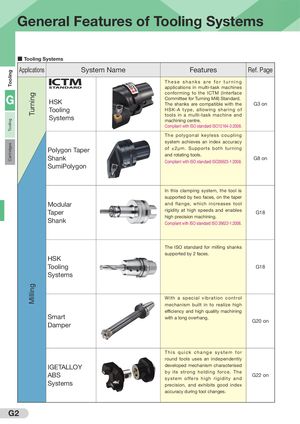

ToolingToolingCartridges TurningMilling General Features of Tooling Systems ■ Tooling Systems Applications System Name Features Ref. Page These shanks are for turning applications in multi-task machines conforming to the ICTM (Interface G HSK Committee for Turning Mill) Standard.The shanks are compatible with theG3 on Tooling HSK-A type, allowing sharing of Systems tools in a multi-task machine andmachining centre. Compliant with ISO standard ISO12164-3:2008. The polygonal keyless coupling system achieves an index accuracy Polygon Taper of ±2μm. Supports both turning Shank and rotating tools. G8 onCompliant with ISO standard ISO26623-1:2008. SumiPolygon In this clamping system, the tool is supported by two faces, on the taper Modular and flange, which increases tool Taper rigidity at high speeds and enables G18 Shank high precision machining.Compliant with ISO standard ISO 26622-1:2008. The ISO standard for milling shanks supported by 2 faces. HSK Tooling G18 Systems With a special vibration control mechanism built in to realize high efficiency and high quality machining Smart with a long overhang. G20 on Damper This quick change system for round tools uses an independently IGETALLOY developed mechanism characterised ABS by its strong holding force. The G22 onsystemoffershighrigidityand Systems precision, and exhibits good index accuracy during tool changes. G2

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019