Общий каталог Sumitomo 2019 - 2020 - страница 361

Навигация

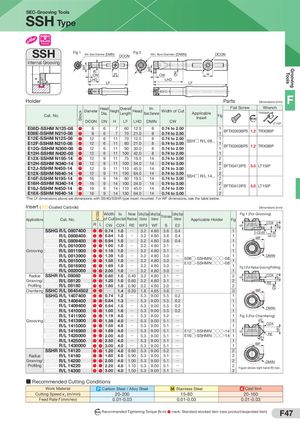

Stock WF DN AC1030U WF DN SSS E2 CWCW WF3WF3WF3 Tools Grooving SEC-Grooving Tools SSH Type Internal SSH Fig 1 Min. Bore Diameter (DMIN) Fig 2DCON Min. Bore Diameter (DMIN) DCON Internal Grooving CW H CW H LHD LHD LF LF Holder Parts Dimensions (mm) F Cat. No. Diameter Head Dia. Height Overall Length Head Min.Bore DiameterWidth of Cut ApplicableInsertFig Flat Screw WrenchTRX08IPNm DCON DN H LF LHD DMIN CW LT15IP E08D-SSHM N125-08 ● 8 6 7 60 12.5 8 0.74 to 2.00E08E-SSHM N210-08●8677021.080.74 to 2.00 11 BFTX02608IPS 1.2 TRX08IP E12E-SSHM N125-08 ● 12 6 11 70 12.5E12F-SSHM N210-08●126118021.0E12G-SSHM N300-08●126119030.08880.74 to 2.000.74 to 2.000.74 to 2.00SSH□ R/L 08...111BFTX02608IPS1.2 TRX08IP E12H-SSHM N420-08 ● 12 6 11 100 42.0 8 0.74 to 2.00 1 E12X-SSHM N195-14 ● 12 9 11 75 19.5 14 0.74 to 3.00 2 E12H-SSHM N340-14 ● 12 9 11 100 34.0 14 0.74 to 3.00E12J-SSHM N450-14●1291111045.0140.74 to 3.00 22 BFTX0412IPS 5.0 LT15IP E12X-SSHM N640-14 ● 12E16F-SSHM N195-14●16911130 64.09148019.51414 0.74 to 3.000.74 to 3.00 SSH□ R/L 14... 22 E16H-SSHM N340-14 ● 16 9 14 100 34.0 14 0.74 to 3.00E16J-SSHM N450-14●1691411045.0140.74 to 3.00 22 BFTX0412IPS 5.0 LT15IP E16X-SSHM N640-14 ● 16 9 14 130 64.0 14 0.74 to 3.00 2 *The LF dimensions above are dimensions with SSHG/SSHR type insert mounted. For WF dimensions, see the table below. Insert ( Coated Carbide) Dimensions (mm) Applications Cat. No. Width of Cut Max. Groove Depth Nose Radius Cutting Edge Distance Cutting Edge Distance Thickness Cutting Edge Distance Applicable Holder Fig 1 (For Grooving)Fig R L CW CDX RE WF3 WF S E2 CDX SSHG R/L 0807400 ●● 0.74 1.0 Q 3.2 4.80 3.6 0.4 1 2-C0.05 SSHG R/L 0808400 ●● 0.84 1.0 Q 3.2 4.80 3.6 0.4 1 WF SSHG R/L 0809400 ●● 0.94 1.0 Q 3.2 4.80 3.6 0.4 1 SSHG R/L 0810000 ●● 1.00 1.0 Q 3.2 4.80 3.1 Q 1 Grooving SSHG R/L 0811900 ●● 1.19 1.0 Q 3.2 4.80 3.1 Q 1 SSHG R/L 0813900SSHG R/L 0815000SSHG R/L 0816900●●1.39 1.0●●1.501.0●●1.691.0QQQ3.2 4.80 3.03.24.803.03.24.803.0QQ E08□-SSHMN○○○-08E12□-SSHMN○○○-0811 DMINQ1Fig 2 (For Radius Grooving/Profiling) SSHG R/L 0820000 ●● 2.00 1.0 Q 3.2 4.80 3.0 Q 1 Radius SSHR R/L 08080 ●● 0.80 1.0 0.40 3.2 4.80 3.1 Q 2 CDX Grooving/ SSHR R/L 08120 ●● 1.20 1.0 0.60 3.2 4.80 3.1 QProfilingSSHR R/L 08180●●1.801.00.903.24.803.0Q 22 RE Chamfering SSHC R/L 08454502 ●● Q 1.4 0.20 1.8 4.65 3.6 Q 3 WF SSHG R/L 1407400 ●● 0.74 1.2 Q 5.3 9.00 5.5 0.2 1 SSHG R/L 1408400 ●● 0.84 1.3 Q 5.3 9.00 5.5 0.2 1 SSHG R/L 1409400 ●● 0.94 1.5 Q 5.3 9.00 5.5 0.2SSHG R/L 1410000●●1.001.6Q5.39.005.50.2 11 DMIN SSHG R/L 1411900 ●● 1.19 4.0 Q 5.3 9.00 5.2 Q 1 Fig 3 (For Chamfering) Grooving SSHG R/L 1413900 ●● 1.39 4.0 Q 5.3 9.00 5.1 Q 1 45° SSHG R/L 1415000 ●● 1.50 4.0 Q 5.3 9.00 5.1 Q 1 CDX SSHG R/L 1416900 ●● 1.69 4.0 Q 5.3 9.00 5.1 Q E12□-SSHMN○○○-14 1 SSHG R/L 1420000 ●● 2.00 4.0 Q 5.3 9.00 5.1 Q E16□-SSHMN○○○-14 1 RE45° SSHG R/L 1425000 ●● 2.50 4.0 Q 5.3 9.00 5.1 Q 1 SSHG R/L 1430000 ●● 3.00 4.0 Q 5.3 9.00 5.1 Q 1 WF SSHR R/L 14120 ●● 1.20 4.0 0.60 5.3 9.00 5.2 Q 2 Radius SSHR R/L 14180 ●● 1.80 4.0 0.90 5.3 9.00 5.1 Q 2 Grooving/ SSHR R/L 14200 ●● 2.00 4.0 1.00 5.3 9.00 5.1 Q 2 DMIN Profiling SSHR R/L 14220 ●● 2.20 4.0 1.10 5.3 9.00 5.1 Q 2 Figure shows right hand (R) tool. SSHR R/L 14300 ●● 3.00 4.0 1.50 5.3 9.00 5.1 Q 2 ■ Recommended Cutting Conditions Work Material P Carbon Steel / Alloy Steel M Stainless Steel K Cast Iron Cutting Speed vc (m/min) 20-200 15-80 20-160 Feed Rate f (mm/rev) 0.01-0.03 0.01-0.03 0.01-0.03 N m Recommended Tightening Torque (N·m) ● mark: Standard stocked item (new product/expanded item) F47

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019