Общий каталог Sumitomo 2019 - 2020 - страница 316

Навигация

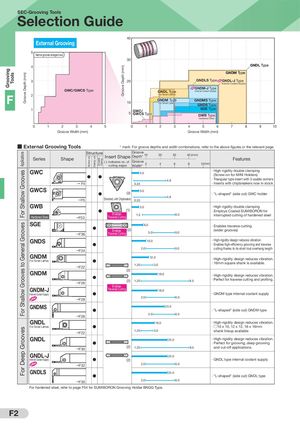

Grooving Tools Groove Depth (mm)ApplicationsFor Shallow GroovesFor Shallow Grooves to General GroovesFor Deep Grooves Screw-on Clamp-on Double Clamp Groove Depth (mm) SEC-Grooving Tools Selection Guide 40 External Grooving 5 Narrow grooves enlarged view 30 4 GNDL Type GNDM Type 3 20 GNDLS Type GNDL-J Type Internal Coolant Supply GWC/GWCS Type GNDM-J TypeGNDL TypeInternal Coolant Supply F 2 For Small LathesGNDM Type GNDMS Type10For Small LathesGNDS Type 1 GWC/ SGE Type 5 GWCS Type GWB Type Hardened Steel 0 1 2 3 4 5 0 1 2 3 4 5 6 7 8 9 10 Groove Width (mm) Groove Width (mm) ■ External Grooving Tools * mark: For groove depths and width combinations, refer to the above figures or the relevant page. Series Shape Structure Insert Shape GrooveDepth* 10 20 30 40 (mm) Features ( ): indicates no. ofcutting edges GrooveWidth*2 4 6 8 10 (mm) GWC · High rigidity double clamping5.0(Screw-on for MINI Holders) 4.8 · Triangular type insert with 3 usable corners → F4 0.33 · Inserts with chipbreakers now in stock GWCS (3) 5.0 · "L-shaped" (side cut) GWC holder →F5 (Standard, with Chipbreaker) 0.33 4.8 GWB 5.0 · High rigidity double clamping (1) · Employs Coated SUMIBORON for Hardened Steel Enables 1.5→F53Traverse Cutting 6.0 interrupted cutting of hardened steel SGE 8.0 · Enables traverse cutting →F36 Enables (2)Traverse Cutting3.0 6.0 (wider grooves) GNDS 10.0 · High-rigidity design reduces vibration. · Enables high-efficiency grooving and traverse →F24 2.0 6.0 cutting thanks to its short tool overhang length GNDMFor Small Lathes 12.0 · High-rigidity design reduces vibration. 1.25 3.0 · 16mm square shank is available. →F22 GNDM (2) 18.0 · High-rigidity design reduces vibration. →F26 (2) 1.25 8.0 · Perfect for traverse cutting and profiling. Enables GNDM-J Traverse Cutting 18.0 Internal Coolant Supply · GNDM type internal coolant supply 2.0 6.0 →F28 GNDMS 23.0 · "L-shaped" (side cut) GNDM type 3.0 6.0 →F26 GNDL 16.0 · High-rigidity design reduces vibration. For Small Lathes · □10 x 10, 12 x 12, 16 x 16mm 1.25 3.0→F22 shank lineup available GNDL 25.0 · High-rigidity design reduces vibration. · Perfect for grooving, deep grooving →F30 (2) 1.25 8.0 and cut-off applications. GNDL-J 25.0 Internal Coolant Supply (2) · GNDL type internal coolant supply →F32 2.0 6.0 GNDLS 25.0 · "L-shaped" (side cut) GNDL type →F30 2.0 6.0 For hardened steel, refer to page F54 for SUMIBORON Grooving Holder BNGG Type. F2

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019