Общий каталог Sumitomo 2019 - 2020 - страница 299

Навигация

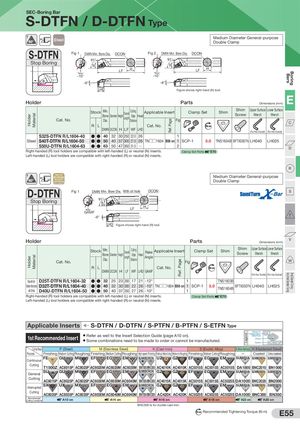

HolderHolder MaterialMaterial WF WF WFRef. Page Ref. Page Legend Very Smal Diameter TurningBars Smal Diameter TurningBoring SEC-Boring Bar S-DTFN / D-DTFN Type 91° Steel Medium Diameter General-purposeDouble Clamp S-DTFN Fig 1 DMIN Min. Bore Dia. DCON Fig 2 DMIN Min. Bore Dia. DCON 91° 91° Stop Boring LF H LF H -10° -10° -6° -6° LHD Figure shows right-hand (R) tool. Holder Parts Dimensions (mm) E Cat. No. Stock Min. Bore Dia. Diameter Height Overal Length Cutting Edge Distance Head Applicable Insert Fig Clamp Set Shim Shim Upper Surface Lower SurfaceScrewWrenchWrench C R L Cat. No. Nm DMIN DCON H LF WF LHD (For Hex Socket) (For Hex Socket) S32S-DTFN R/L1604-40 ●● 40 32 30 250 22.0 26 1 Steel S40T-DTFN R/L1604-50 ●● 50 40 37 300 27.0 26 TN□□1604 B56 on 1 SCP-1 5.0 TNS1604B BFTX0307N LH040 LH025 S50U-DTFN R/L1604-63 ●● 63 50 47 350 31.5 Q 2 D Right-handed (R) tool holders are compatible with left-handed (L) or neutral (N) inserts. Clamp Set Parts E70 Left-handed (L) tool holders are compatible with right-handed (R) or neutral (N) inserts. R Steel with91°Anti-Vibration Medium Diameter General-purpose MechanismCoolant Hole Double Clamp D-DTFN Fig 1 DMIN Min. Bore Dia. With oil hole DCON S Stop Boring 91° LF H GAMF -6° T LHD Figure shows right-hand (R) tool. Holder Parts VDimensions (mm) Cat. No. Stock Min. Bore Dia. Diameter Height Overal Length Cutting Edge Distance Head Rake Angle Applicable Insert Fig Clamp Set Shim Shim Upper Surface Lower SurfaceScrewWrenchWrench W R L Cat. No. Nm DMIN DCON H LF WF LHD GAMF (For Hex Socket) (For Hex Socket) Steel with Anti- D25T-DTFN R/L1604-32 ●● 32 25 23 300 17 21 -12° 1 TNS1603B Vibration Mechanism D32T-DTFN R/L1604-40 ●● 40 32 30 300 22 26 -10° TN□□1604 B56 on 1 SCP-1with Oil HoleD40U-DTFN R/L1604-50●●504037 3502726-10°15.0TNS1604B BFTX0307N LH040LH025 Right-handed (R) tool holders are compatible with left-handed (L) or neutral (N) inserts. Clamp Set Parts E70 Left-handed (L) tool holders are compatible with right-handed (R) or neutral (N) inserts. Applicable Inserts S-DTFN / D-DTFN / S-PTFN / B-PTFN / S-ETFN Type 1st Recommended Insert ● Refer as well to the Insert Selection Guide (page A10 on).● Some combinations need to be made to order or cannot be manufactured. Name ofChipbreaker/GUCBN/PCDPhotoGradeAC8025P Cutting Range P (Steel) M (Stainless Steel) K (Cast Iron) S (Exotic Alloy) N (Non-ferrous) H (Hardened Steel) Process Finishing Medium Cutting Roughing Finishing Medium Cutting Roughing High-speed Finishing FinishingtoMediumCutting Medium to Roughing Finishing Medium Cutting Roughing — Coated Uncoated Continuous FE GU MU EF EG EM SUMIBORON UZ GZ EF EG EM SUMIDIA SUMIBORON SUMIBORON Cutting T1500Z AC8015P AC8025P AC6020M AC6020M AC6030M BN7000/BNC500 AC4010K AC4010K AC5015S AC5015S AC5015S DA1000 BNC2010 BN1000 General SU GU MU EF EG EM SUMIBORON GZ GZ EF EG EM SUMIDIA SUMIBORON SUMIBORON Cutting AC8015P AC8025P AC8025P AC6030M AC6030M AC6040M BN7000/BNC500 AC4015K AC4015K AC5015S AC5015S AC5025S DA1000 BNC2020 BN2000 Interrupted SX UX MX EF EG EM SUMIBORON GZ GZ EF EG EM SUMIDIA SUMIBORON SUMIBORON Cutting AC8025P AC8035P AC8035P AC6030M AC6040M AC6040M BN7000/BNC500 AC420K AC420K AC5025S AC5025S AC5025S DA1000 BNC300 BN350 RecommendedCutting Conditions A10 on A14 on A16 on A18 on A22 on A20 on BNC500 is for ductile cast iron. N m Recommended Tightening Torque (N·m) E55

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019