Общий каталог Sumitomo 2019 - 2020 - страница 297

Навигация

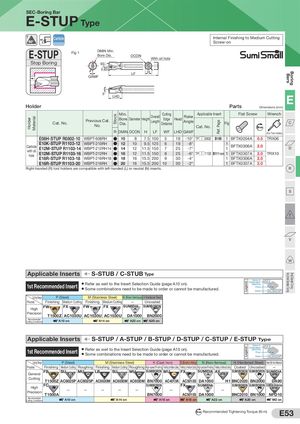

Holder Material WF Stock Ref. Page LegendLegend Very Smal Diameter TurningBars Smal Diameter TurningBoring SEC-Boring Bar E-STUP Type 93˚ Carbide Internal Finishing to Medium Cutting Coolant Hole Screw-on E-STUP Fig 1 DMIN Min.Bore Dia. DCON With oil hole Stop Boring 93˚ LF H GAMF 5° LHD E Holder Parts Dimensions (mm) Cat. No. Previous Cat.No. Min.BoreDia.Diameter Height Overall LengthCuttingEdgeDistanceHeadRakeAngleApplicable InsertFigCat. No. Flat Screw Wrench CNm R DMIN DCON H LF WF LHD GAMF (For Torx Holes) E08H-STUP R0802-10 WBPT-608RH ● 10 8 7.5 100 5 18 -10° TP□□0802 B109 1 BFTX0204A 0.5 TRX06 E10K-STUP R1103-12 WBPT-210RH ● 12 10 9.5 125 6Carbidewith oilholeE12M-STUP R1103-14E12M-STUP R1103-16WBPT-212RH14●WBPT-212RH●14161211.515071211.5150819-8°25-7°11BFTX0306A2.025-6°TP□□1103B111 on1BFTX0307A2.0TRX10D E16R-STUP R1103-18 WBPT-216RH18 ● 18 16 15.5 200 9 30 -4° 1 BFTX0306A 2.0 E16R-STUP R1103-20 WBPT-216RH ● 20 16 15.5 200 10 30 -2° 1 BFTX0307A 2.0 Right-handed (R) tool holders are compatible with left-handed (L) or neutral (N) inserts. R S T V W Applicable Inserts S-STUB / C-STUB Type 1st Recommended Insert ● Refer as well to the Insert Selection Guide (page A10 on).● Some combinations need to be made to order or cannot be manufactured. Name ofChipbreaker/GUCBN/PCDPhotoGradeAC8025P Cutting Range P (Steel) M (Stainless Steel) N (Non-ferrous) H (Hardened Steel) Process Finishing Medium Cutting Finishing Medium Cutting — Uncoated High FW FX FW FX SUMIDIA SUMIBORON Precision T1500Z AC1030U AC1030U AC1030U DA1000 BN2000 RecommendedCutting Conditions A10 on A14 on A22 on A20 on Applicable Inserts S-STUP / A-STUP / B-STUP / D-STUP / C-STUP / E-STUP Type 1st Recommended Insert ● Refer as well to the Insert Selection Guide (page A10 on).● Some combinations need to be made to order or cannot be manufactured. Name ofChipbreaker/GUCBN/PCDPhotoGradeAC8025P Cutting Range P (Steel) M (Stainless Steel) K (Cast Iron) S (Exotic Alloy) N (Non-ferrous) H (Hardened Steel) Hard Brittle Material Process Finishing Medium Cutting Roughing Finishing Medium Cutting Roughing High-speed Finishing FinishingtoMediumCutting Finishing to Medium Cutting High-precision/Finishing Finishing to Medium Cutting Coated Uncoated — General FB SU MU LB SU MU SUMIBORON MU FX SUMIDIA AY SUMIBORON SUMIBORON SUMIDIA Cutting T1500Z AC8025P AC8025P AC6030M AC6030M AC6030M BN7000 AC4015K AC5015S DA1000 H1 BNC2020 BN2000 DA90 High FCPrecisionT1500A — — — — SUMIBORON FX SUMIDIA SUMIBORON SUMIBORON SUMIDIA Binderless———BN7000AC5015SDA1000BNC2010BN1000NPD10 RecommendedCutting Conditions A10 on A14 on A16 on A18 on A22 on A20 on M2 on N m Recommended Tightening Torque (N·m) E53

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019