Каталог Sumitomo модульные фрезерные системы - страница 9

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

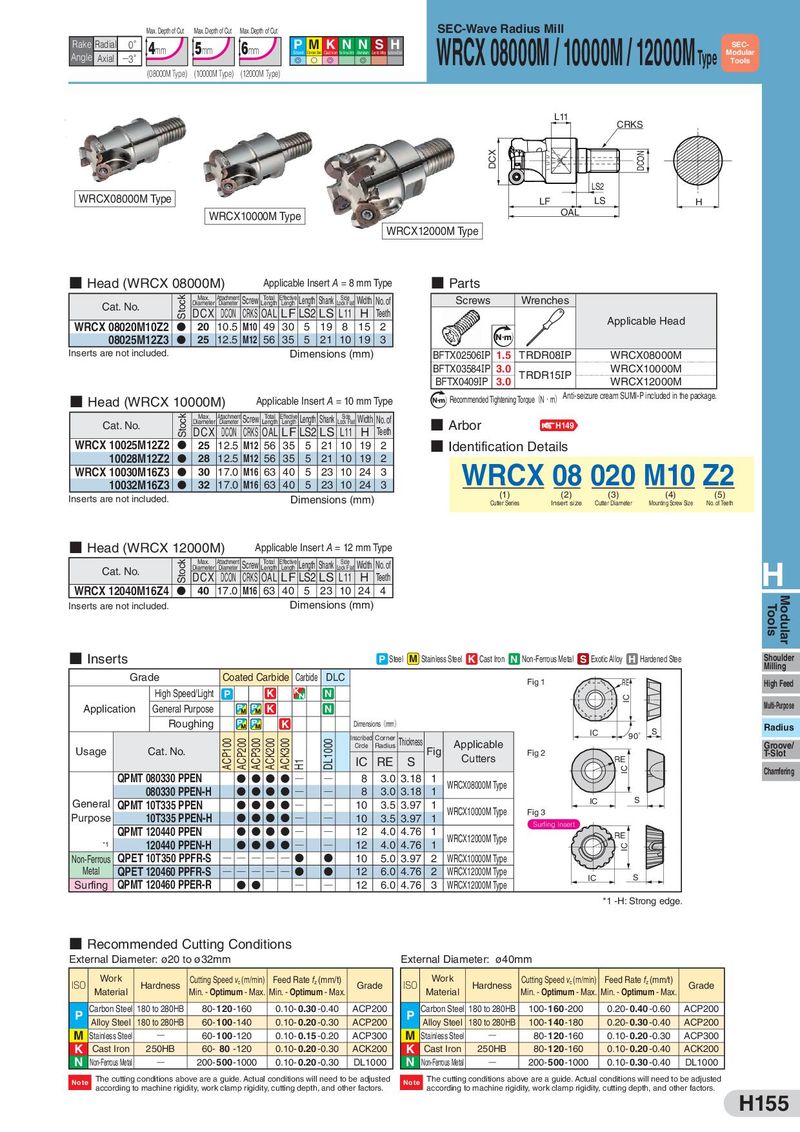

Max. Depth of Cut Max. Depth of Cut Max. Depth of Cut SEC-Wave Radius Mill Rake Radial 0° 4mm 5mm 6mm P M K N N SH WRCX 08000M / 10000M / 12000MType SEC- Angle Axial Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel Modular −3° G S G G Tools (08000M Type) (10000M Type) (12000M Type) L11 CRKS DCX DCON LS2 WRCX08000M Type LF LS H WRCX10000M Type OAL WRCX12000M Type ■ Head (WRCX 08000M) Applicable Insert A = 8 mm Type ■ Parts Stock Max. Attachment Screw Total Effective Length Shank Side Width No. of Screws Wrenches Diameter Diameter Length Length Lock Flat Cat. No. DCX DCON CRKS OAL LF LS2 LS L11 H Teeth Applicable Head WRCX 08020M10Z2 D 20 10.5 M10 49 30 5 19 8 15 2 08025M12Z3 D 25 12.5 M12 56 35 5 21 10 19 3 Nm Inserts are not included. Dimensions (mm) BFTX02506IP 1.5 TRDR08IP WRCX08000M BFTX03584IP 3.0 TRDR15IP WRCX10000M BFTX0409IP 3.0 WRCX12000M ■ Head (WRCX 10000M) Applicable Insert A = 10 mm Type N m Recommended Tightening Torque(N・m) Anti-seizure cream SUMI-P included in the package. Stock Max. Attachment Screw Total Effective Length Shank Side Width No. of Diameter Diameter Length Length Lock Flat ■ Arbor Cat. No. H149 DCX DCON CRKS OAL LF LS2 LS L11 H Teeth WRCX 10025M12Z2 D 25 12.5 M12 56 35 5 21 10 19 2 ■ Identification Details 10028M12Z2 D 28 12.5 M12 56 35 5 21 10 19 2 WRCX 08 020 M10 Z2 WRCX 10030M16Z3 D 30 17.0 M16 63 40 5 23 10 24 3 10032M16Z3 D 32 17.0 M16 63 40 5 23 10 24 3 Inserts are not included. Dimensions (mm) (1) (2) (3) (4) (5) Cutter Series Insert size Cutter Diameter Mounting Screw Size No. of Teeth ■ Head (WRCX 12000M) Applicable Insert A = 12 mm Type Stock Max. Attachment Screw Total Effective Length Shank Side Width No. of H Diameter Diameter Length Length Lock Flat Cat. No. DCX DCON CRKS OAL LF LS2 LS L11 H Teeth WRCX 12040M16Z4 D 40 17.0 M16 63 40 5 23 10 24 4 Modular Inserts are not included. Dimensions (mm) Tools ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Stee Shoulder Milling Grade Coated Carbide Carbide DLC Fig 1 RE High Feed High Speed/Light P K N IC Application General Purpose K N Multi-Purpose Roughing K Dimensions(mm) Radius Inscribed Corner IC 90° S Usage Cat. No. ACP100 ACP200 ACP300 ACK200 ACK300 DL1000 Circle Radius Thickness Fig Applicable Groove/ IC RE S Cutters Fig 2 RE T-Slot H1 IC Chamfering QPMT 080330 PPEN D D D D Q Q 8 3.0 3.18 1 WRCX08000M Type 080330 PPEN-H D D D D Q Q 8 3.0 3.18 1 S General QPMT 10T335 PPEN D D D D Q Q 10 3.5 3.97 1 IC Purpose 10T335 PPEN-H D D D D Q Q 10 3.5 3.97 1 WRCX10000M Type Fig 3 QPMT 120440 PPEN D D D D Q Q 12 4.0 4.76 1 Surfing Insert WRCX12000M Type RE *1 120440 PPEN-H D D D D Q Q 12 4.0 4.76 1 IC Non-Ferrous QPET 10T350 PPFR-S Q Q Q Q Q D D 10 5.0 3.97 2 WRCX10000M Type Metal QPET 120460 PPFR-S Q Q Q Q Q D D 12 6.0 4.76 2 WRCX12000M Type IC S Surfing QPMT 120460 PPER-R D D Q Q 12 6.0 4.76 3 WRCX12000M Type *1 -H: Strong edge. ■ Recommended Cutting Conditions External Diameter: ø20 to ø32mm External Diameter: ø40mm ISO Work Hardness Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade ISO Work Hardness Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade Material Min. - Optimum - Max. Min. - Optimum - Max. Material Min. - Optimum - Max. Min. - Optimum - Max. P Carbon Steel 180 to 280HB 80- 120 -160 0.10- 0.30 -0.40 ACP200 P Carbon Steel 180 to 280HB 100- 160 -200 0.20- 0.40 -0.60 ACP200 Alloy Steel 180 to 280HB 60- 100 -140 0.10- 0.20 -0.30 ACP200 Alloy Steel 180 to 280HB 100- 140 -180 0.20- 0.30 -0.40 ACP200 M Stainless Steel Q 60- 100 -120 0.10- 0.15 -0.20 ACP300 M Stainless Steel Q 80- 120 -160 0.10- 0.20 -0.30 ACP300 K Cast Iron 250HB 60- 80 -120 0.10- 0.20 -0.30 ACK200 K Cast Iron 250HB 80- 120 -160 0.10- 0.20 -0.40 ACK200 N Non-Ferrous Metal Q 200- 500 -1000 0.10- 0.20 -0.30 DL1000 N Non-Ferrous Metal Q 200- 500 -1000 0.10- 0.30 -0.40 DL1000 Note The cutting conditions above are a guide. Actual conditions will need to be adjusted Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to machine rigidity, work clamp rigidity, cutting depth, and other factors. according to machine rigidity, work clamp rigidity, cutting depth, and other factors. H155

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Техническая информация Sumitomo

Техническая информация Sumitomo