Каталог Sumitomo инструмент для отрезки - страница 7

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

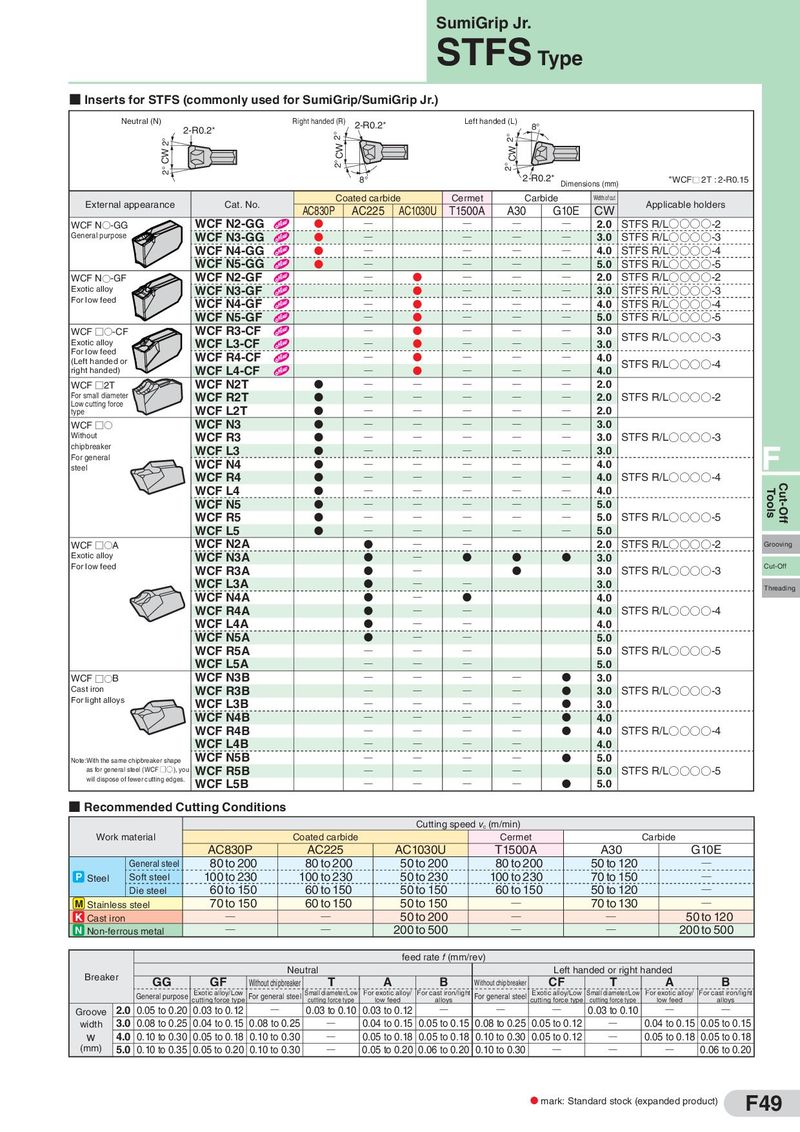

SumiGrip Jr. STFS Type ■ Inserts for STFS (commonly used for SumiGrip/SumiGrip Jr.) Neutral (N) Right handed (R) 2-R0.2* Left handed (L) 8° 2-R0.2* 2°CW 2° 2° CW 2° 2° CW 2° 8° 2-R0.2* Dimensions (mm) *WCF□ 2T : 2-R0.15 External appearance Cat. No. Coated carbide Cermet Carbide Width of cut Applicable holders AC830P AC225 AC1030U T1500A A30 G10E CW WCF N○-GG WCF N2-GG D Q Q Q Q 2.0 STFS R/L○○○○-2 General purpose WCF N3-GG D Q Q Q Q 3.0 STFS R/L○○○○-3 WCF N4-GG D Q Q Q Q 4.0 STFS R/L○○○○-4 WCF N5-GG D Q Q Q Q 5.0 STFS R/L○○○○-5 WCF N○-GF WCF N2-GF Q D Q Q Q 2.0 STFS R/L○○○○-2 Exotic alloy WCF N3-GF Q D Q Q Q 3.0 STFS R/L○○○○-3 For low feed WCF N4-GF Q D Q Q Q 4.0 STFS R/L○○○○-4 WCF N5-GF Q D Q Q Q 5.0 STFS R/L○○○○-5 WCF □○-CF WCF R3-CF Q D Q Q Q 3.0 STFS R/L○○○○-3 Exotic alloy WCF L3-CF Q D Q Q Q 3.0 For low feed WCF R4-CF Q D Q Q Q 4.0 (Left handed or STFS R/L○○○○-4 right handed) WCF L4-CF Q D Q Q Q 4.0 WCF □2T WCF N2T D Q Q Q Q Q 2.0 For small diameter WCF R2T D Q Q Q Q Q 2.0 STFS R/L○○○○-2 Low cutting force WCF L2T D Q Q Q Q Q 2.0 type WCF □○ WCF N3 D Q Q Q Q Q 3.0 Without WCF R3 D Q Q Q Q Q 3.0 STFS R/L○○○○-3 chipbreaker WCF L3 D Q Q Q Q Q 3.0 F For general WCF N4 D Q Q Q Q Q 4.0 steel WCF R4 D Q Q Q Q Q 4.0 STFS R/L○○○○-4 Cut-Off WCF L4 D Q Q Q Q Q 4.0 Tools WCF N5 D Q Q Q Q Q 5.0 WCF R5 D Q Q Q Q Q 5.0 STFS R/L○○○○-5 WCF L5 D Q Q Q Q Q 5.0 WCF □○A WCF N2A D Q Q 2.0 STFS R/L○○○○-2 Grooving Exotic alloy WCF N3A D Q D D D 3.0 For low feed WCF R3A D Q D 3.0 STFS R/L○○○○-3 Cut-Off WCF L3A D Q Q 3.0 Threading WCF N4A D Q D 4.0 WCF R4A D Q Q 4.0 STFS R/L○○○○-4 WCF L4A D Q Q 4.0 WCF N5A D Q Q 5.0 WCF R5A Q Q Q 5.0 STFS R/L○○○○-5 WCF L5A Q Q Q 5.0 WCF □○B WCF N3B Q Q Q Q D 3.0 Cast iron WCF R3B Q Q Q Q D 3.0 STFS R/L○○○○-3 For light alloys WCF L3B Q Q Q Q D 3.0 WCF N4B Q Q Q Q D 4.0 WCF R4B Q Q Q Q D 4.0 STFS R/L○○○○-4 WCF L4B Q Q Q Q 4.0 Note:With the same chipbreaker shape WCF N5B Q Q Q Q D 5.0 as for general steel (WCF □◯ ), you WCF R5B Q Q Q Q 5.0 STFS R/L○○○○-5 will dispose of fewer cutting edges. WCF L5B Q Q Q Q D 5.0 ■ Recommended Cutting Conditions Cutting speed vc (m/min) Work material Coated carbide Cermet Carbide AC830P AC225 AC1030U T1500A A30 G10E General steel 80 to 200 80 to 200 50 to 200 80 to 200 50 to 120 Q P Steel Soft steel 100 to 230 100 to 230 50 to 230 100 to 230 70 to 150 Q Die steel 60 to 150 60 to 150 50 to 150 60 to 150 50 to 120 Q M Stainless steel 70 to 150 60 to 150 50 to 150 Q 70 to 130 Q K Cast iron Q Q 50 to 200 Q Q 50 to 120 N Non-ferrous metal Q Q 200 to 500 Q Q 200 to 500 feed rate f (mm/rev) Breaker Neutral Left handed or right handed GG GF Without chipbreaker T A B Without chipbreaker CF T A B General purpose Exotic alloy/Low For general steel Small diameter/Low For exotic alloy/ For cast iron/light For general steel Exotic alloy/Low Small diameter/Low For exotic alloy/ For cast iron/light cutting force type cutting force type low feed alloys cutting force type cutting force type low feed alloys Groove 2.0 0.05 to 0.20 0.03 to 0.12 Q 0.03 to 0.10 0.03 to 0.12 Q Q Q 0.03 to 0.10 Q Q width 3.0 0.08 to 0.25 0.04 to 0.15 0.08 to 0.25 Q 0.04 to 0.15 0.05 to 0.15 0.08 to 0.25 0.05 to 0.12 Q 0.04 to 0.15 0.05 to 0.15 w 4.0 0.10 to 0.30 0.05 to 0.18 0.10 to 0.30 Q 0.05 to 0.18 0.05 to 0.18 0.10 to 0.30 0.05 to 0.12 Q 0.05 to 0.18 0.05 to 0.18 (mm) 5.0 0.10 to 0.35 0.05 to 0.20 0.10 to 0.30 Q 0.05 to 0.20 0.06 to 0.20 0.10 to 0.30 Q Q Q 0.06 to 0.20 D mark: Standard stock (expanded product) F49

Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Техническая информация Sumitomo

Техническая информация Sumitomo