Каталог Sumitomo инструмент для отрезки - страница 2

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

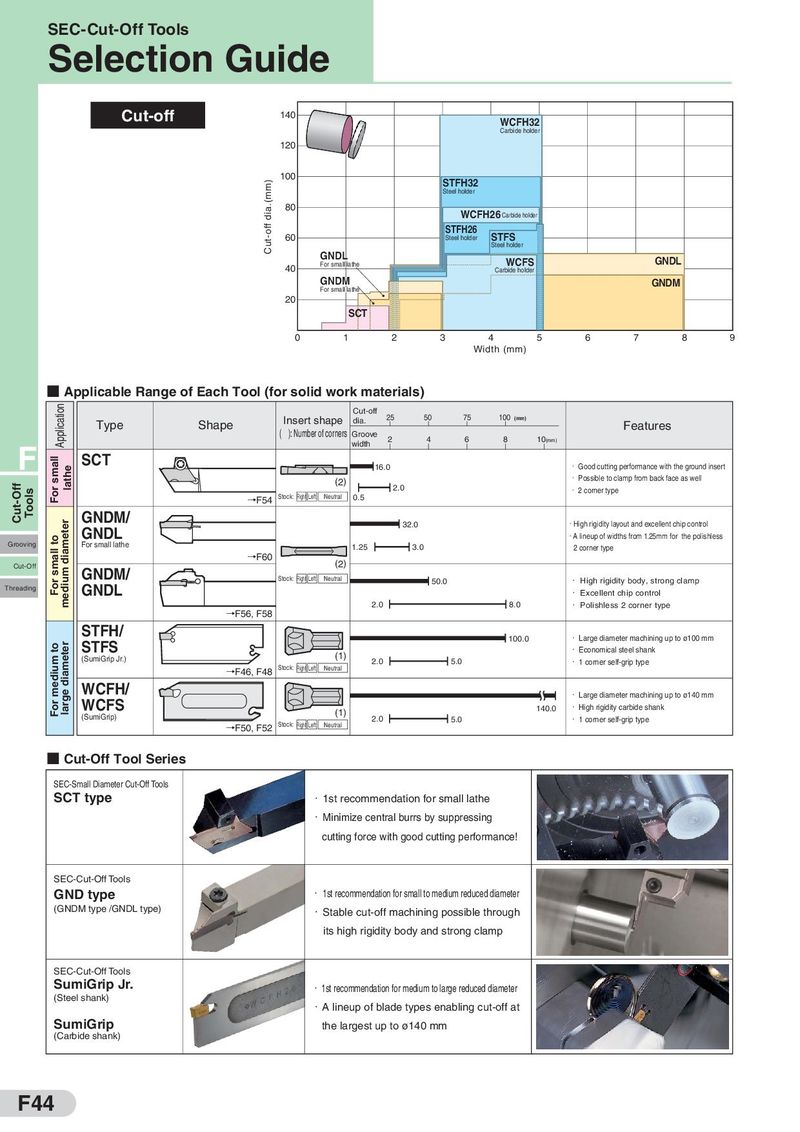

SEC-Cut-Off Tools Selection Guide Cut-off 140 WCFH32 Carbide holder 120 Cut-off dia.(mm) 100 STFH32 Steel holder 80 WCFH26 Carbide holder 60 STFH26 STFS Steel holder Steel holder GNDL WCFS GNDL 40 For small lathe Carbide holder GNDM GNDM For small lathe 20 SCT 0 1 2 3 4 5 6 7 8 9 Width (mm) ■ Applicable Range of Each Tool (for solid work materials) Application Cut-off 25 50 75 100 Type Shape Insert shape dia. (mm) Features ( ): Number of corners Groove 2 4 6 8 10(mm) F width For small lathe SCT 16.0 ・ Good cutting performance with the ground insert (2) ・ Possible to clamp from back face as well Cut-Off Tools 2.0 ・ 2 corner type →F54 Stock: Right Left Neutral 0.5 medium diameter GNDM/ 32.0 ・High rigidity layout and excellent chip control For small to GNDL ・A lineup of widths from 1.25mm for the polishless Grooving For small lathe 1.25 3.0 2 corner type →F60 (2) Cut-Off GNDM/ Stock: Right Left Neutral 50.0 ・ High rigidity body, strong clamp Threading GNDL ・ Excellent chip control 2.0 8.0 ・ Polishless 2 corner type →F56, F58 STFH/ 100.0 ・ Large diameter machining up to ø100 mm For medium to large diameter STFS (1) ・ Economical steel shank (SumiGrip Jr.) 2.0 5.0 ・ 1 corner self-grip type →F46, F48 Stock: Right Left Neutral WCFH/ ・ Large diameter machining up to ø140 mm WCFS (1) 140.0 ・ High rigidity carbide shank (SumiGrip) 2.0 5.0 ・ 1 corner self-grip type →F50, F52 Stock: Right Left Neutral ■ Cut-Off Tool Series SEC-Small Diameter Cut-Off Tools SCT type ・ 1st recommendation for small lathe ・ Minimize central burrs by suppressing cutting force with good cutting performance! SEC-Cut-Off Tools GND type ・ 1st recommendation for small to medium reduced diameter (GNDM type /GNDL type) ・ Stable cut-off machining possible through its high rigidity body and strong clamp SEC-Cut-Off Tools SumiGrip Jr. ・1st recommendation for medium to large reduced diameter (Steel shank) ・A lineup of blade types enabling cut-off at SumiGrip the largest up to ø140 mm (Carbide shank) F44

Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Техническая информация Sumitomo

Техническая информация Sumitomo