Каталог Stellram высокопроизводительные фрезерные системы - страница 75

Навигация

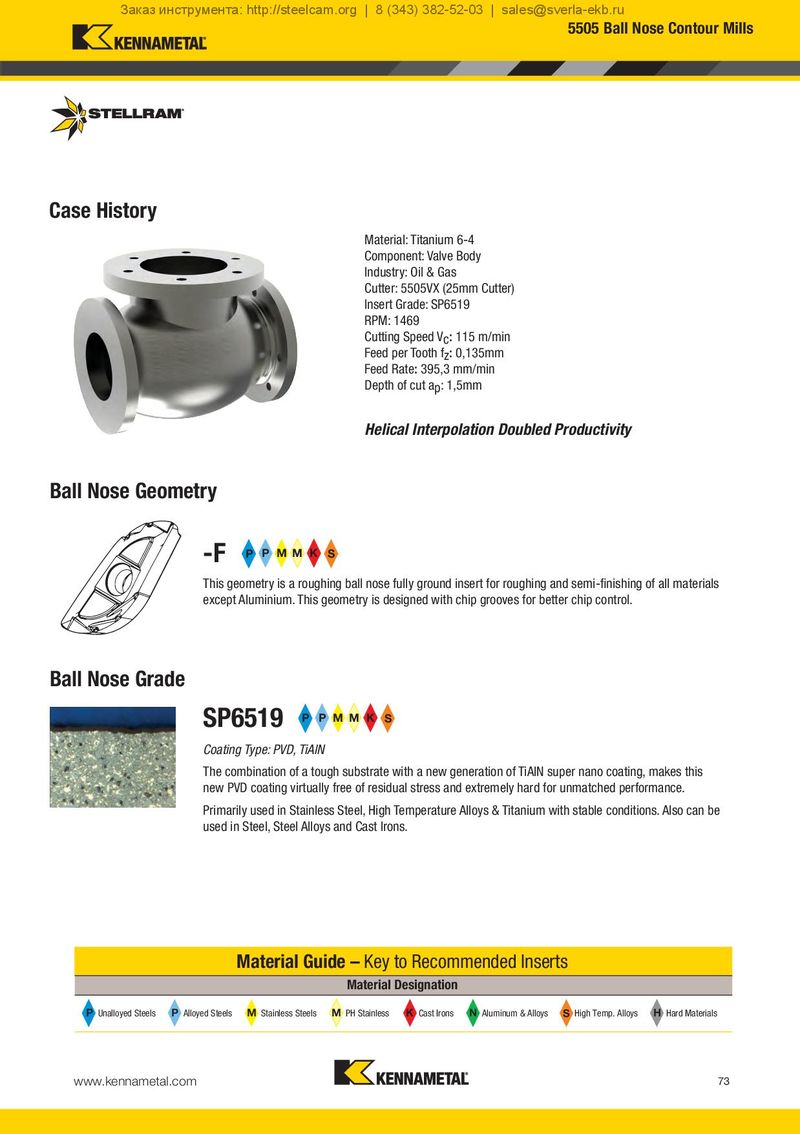

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 5505 Ball Nose Contour Mills Case History Material: Titanium 6-4 Component: Valve Body Industry: Oil & Gas Cutter: 5505VX (25mm Cutter) Insert Grade: SP6519 RPM: 1469 Cutting Speed Vc: 115 m/min Feed per Tooth fz: 0,135mm Feed Rate: 395,3 mm/min Depth of cut ap: 1,5mm Helical Interpolation Doubled Productivity Ball Nose Geometry -F P P M M K S This geometry is a roughing ball nose fully ground insert for roughing and semi-finishing of all materials except Aluminium. This geometry is designed with chip grooves for better chip control. Ball Nose Grade SP6519 P P M M K S Coating Type: PVD, TiAlN The combination of a tough substrate with a new generation of TiAlN super nano coating, makes this new PVD coating virtually free of residual stress and extremely hard for unmatched performance. Primarily used in Stainless Steel, High Temperature Alloys & Titanium with stable conditions. Also can be used in Steel, Steel Alloys and Cast Irons. Material Guide – Key to Recommended Inserts Material Designation P Unalloyed Steels P Alloyed Steels M Stainless Steels M PH Stainless K Cast Irons N Aluminum & Alloys S High Temp. Alloys H Hard Materials www.kennametal.com 73

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами