Каталог Stellram фрез со сменными пластинами - страница 76

Навигация

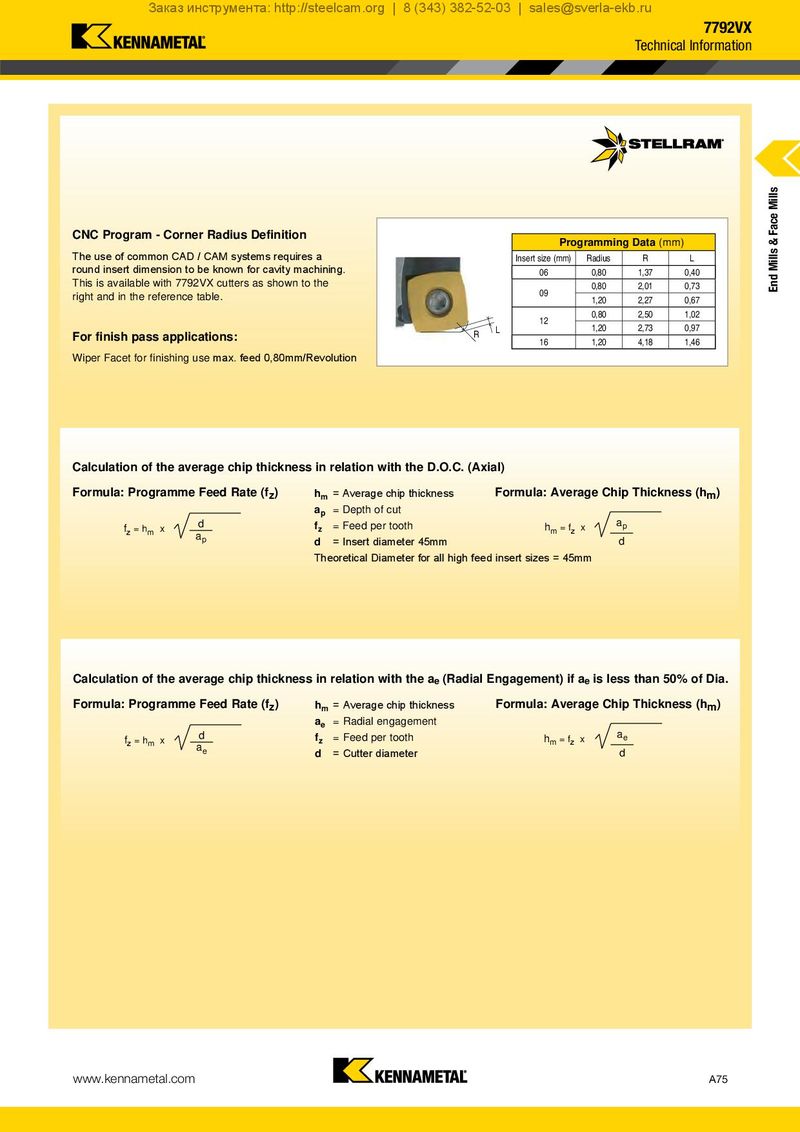

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 7792VX Technical Information CNC Program - Corner Radius Definition Programming Data (mm) End Mills & Face Mills The use of common CAD / CAM systems requires a Insert size (mm) Radius R L round insert dimension to be known for cavity machining. 06 0,80 1,37 0,40 This is available with 7792VX cutters as shown to the 0,80 2,01 0,73 right and in the reference table. 09 1,20 2,27 0,67 12 0,80 2,50 1,02 For finish pass applications: R L 1,20 2,73 0,97 16 1,20 4,18 1,46 Wiper Facet for finishing use max. feed 0,80mm/Revolution Calculation of the average chip thickness in relation with the D.O.C. (Axial) Formula: Programme Feed Rate (fz) hm = Average chip thickness Formula: Average Chip Thickness (hm) ap = Depth of cut fz = hm x d fz = Feed per tooth hm = fz x ap ap d = Insert diameter 45mm d Theoretical Diameter for all high feed insert sizes = 45mm Calculation of the average chip thickness in relation with the ae (Radial Engagement) if ae is less than 50% of Dia. Formula: Programme Feed Rate (fz) hm = Average chip thickness Formula: Average Chip Thickness (hm) ae = Radial engagement fz = hm x d fz = Feed per tooth hm = fz x ae ae d = Cutter diameter d www.kennametal.com A75

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы