Каталог Stellram фрез со сменными пластинами - страница 288

Навигация

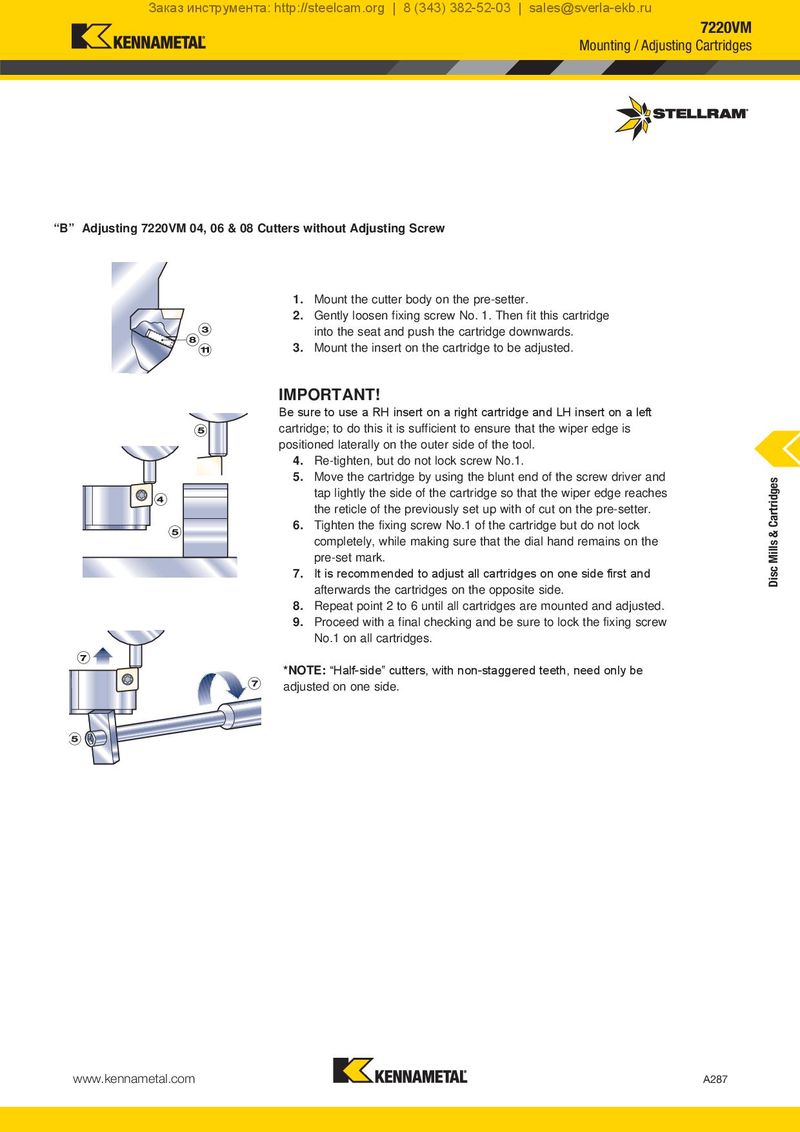

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 7220VM Mounting / Adjusting Cartridges “B” Adjusting 7220VM 04, 06 & 08 Cutters without Adjusting Screw 1. Mount the cutter body on the pre-setter. 2. Gently loosen fixing screw No. 1. Then fit this cartridge into the seat and push the cartridge downwards. 3. Mount the insert on the cartridge to be adjusted. IMPORTANT! Be sure to use a RH insert on a right cartridge and LH insert on a left cartridge; to do this it is sufficient to ensure that the wiper edge is positioned laterally on the outer side of the tool. 4. Re-tighten, but do not lock screw No.1. 5. Move the cartridge by using the blunt end of the screw driver and Disc Mills & Cartridges tap lightly the side of the cartridge so that the wiper edge reaches the reticle of the previously set up with of cut on the pre-setter. 6. Tighten the fixing screw No.1 of the cartridge but do not lock completely, while making sure that the dial hand remains on the pre-set mark. 7. It is recommended to adjust all cartridges on one side first and afterwards the cartridges on the opposite side. 8. Repeat point 2 to 6 until all cartridges are mounted and adjusted. 9. Proceed with a final checking and be sure to lock the fixing screw No.1 on all cartridges. *NOTE: “Half-side” cutters, with non-staggered teeth, need only be adjusted on one side. www.kennametal.com A287

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы