Каталог Stellram фрез со сменными пластинами - страница 249

Навигация

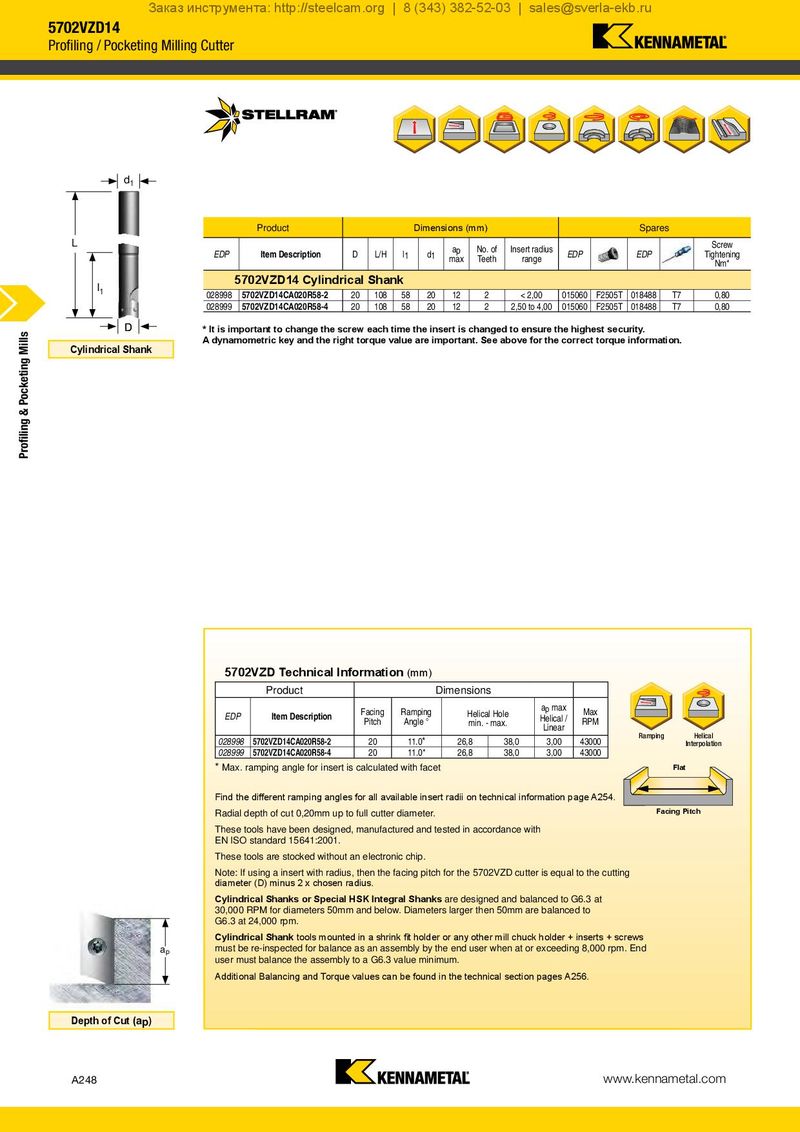

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 5702VZD14 Profiling / Pocketing Milling Cutter d1 Product Dimensions (mm) Spares L ap No. of Insert radius Screw EDP Item Description D L/H l1 d1 max Teeth range EDP EDP Tightening Nm* I1 5702VZD14 Cylindrical Shank 028998 5702VZD14CA020R58-2 20 108 58 20 12 2 < 2,00 015060 F2505T 018488 T7 0,80 028999 5702VZD14CA020R58-4 20 108 58 20 12 2 2,50 to 4,00 015060 F2505T 018488 T7 0,80 Profiling & Pocketing Mills D * It is important to change the screw each time the insert is changed to ensure the highest security. Cylindrical Shank A dynamometric key and the right torque value are important. See above for the correct torque information. 5702VZD Technical Information (mm) Product Dimensions EDP Item Description Facing Ramping Helical Hole ap max Max Pitch Angle ° min. - max. Helical / RPM Linear Ramping Helical 028998 5702VZD14CA020R58-2 20 11.0* 26,8 38,0 3,00 43000 Interpolation 028999 5702VZD14CA020R58-4 20 11.0* 26,8 38,0 3,00 43000 * Max. ramping angle for insert is calculated with facet Flat Find the different ramping angles for all available insert radii on technical information page A254. Radial depth of cut 0,20mm up to full cutter diameter. Facing Pitch These tools have been designed, manufactured and tested in accordance with EN ISO standard 15641:2001. These tools are stocked without an electronic chip. Note: If using a insert with radius, then the facing pitch for the 5702VZD cutter is equal to the cutting diameter (D) minus 2 x chosen radius. Cylindrical Shanks or Special HSK Integral Shanks are designed and balanced to G6.3 at 30,000 RPM for diameters 50mm and below. Diameters larger then 50mm are balanced to G6.3 at 24,000 rpm. Cylindrical Shank tools mounted in a shrink fit holder or any other mill chuck holder + inserts + screws ap must be re-inspected for balance as an assembly by the end user when at or exceeding 8,000 rpm. End user must balance the assembly to a G6.3 value minimum. Additional Balancing and Torque values can be found in the technical section pages A256. Depth of Cut (ap) A248 www.kennametal.com

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы