Каталог Stellram фрез со сменными пластинами - страница 24

Навигация

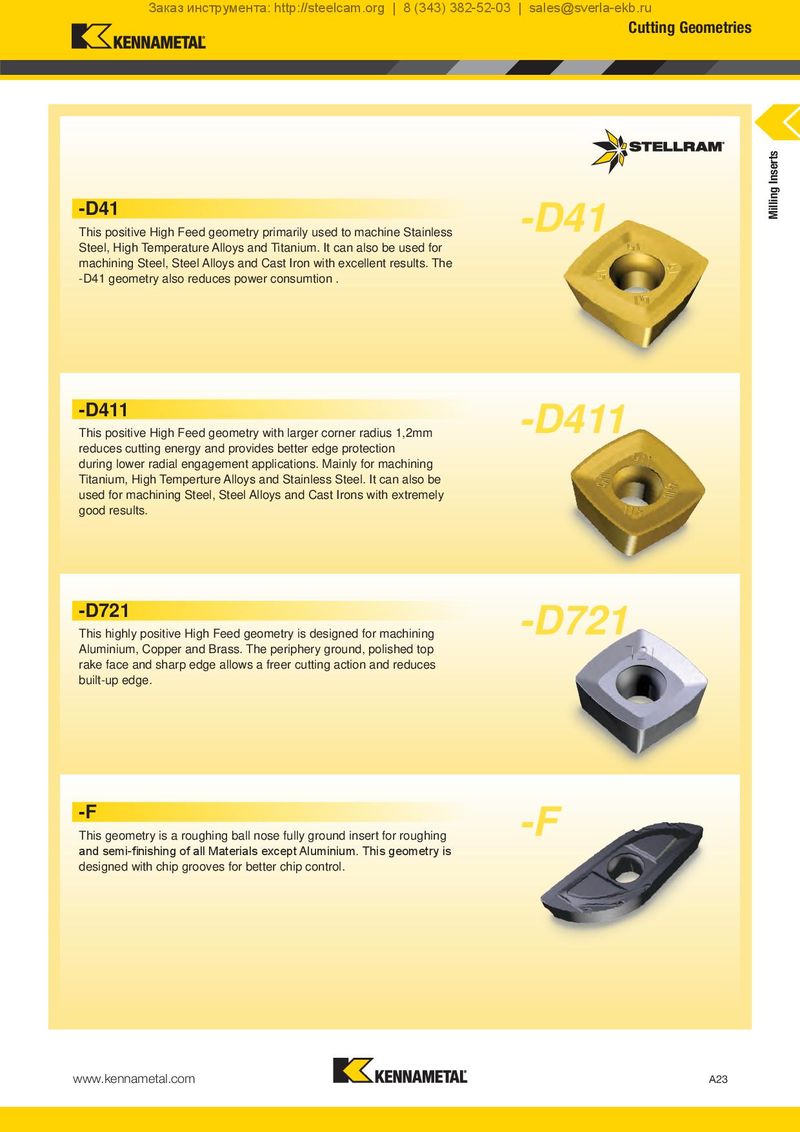

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru Cutting Geometries -D41 -D41 Milling Inserts This positive High Feed geometry primarily used to machine Stainless Steel, High Temperature Alloys and Titanium. It can also be used for machining Steel, Steel Alloys and Cast Iron with excellent results. The -D41 geometry also reduces power consumtion . -D411 -D411 This positive High Feed geometry with larger corner radius 1,2mm reduces cutting energy and provides better edge protection during lower radial engagement applications. Mainly for machining Titanium, High Temperture Alloys and Stainless Steel. It can also be used for machining Steel, Steel Alloys and Cast Irons with extremely good results. -D721 -D721 This highly positive High Feed geometry is designed for machining Aluminium, Copper and Brass. The periphery ground, polished top rake face and sharp edge allows a freer cutting action and reduces built-up edge. -F -F This geometry is a roughing ball nose fully ground insert for roughing and semi-finishing of all Materials except Aluminium. This geometry is designed with chip grooves for better chip control. www.kennametal.com A23

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы