Каталог Stellram фрез со сменными пластинами - страница 228

Навигация

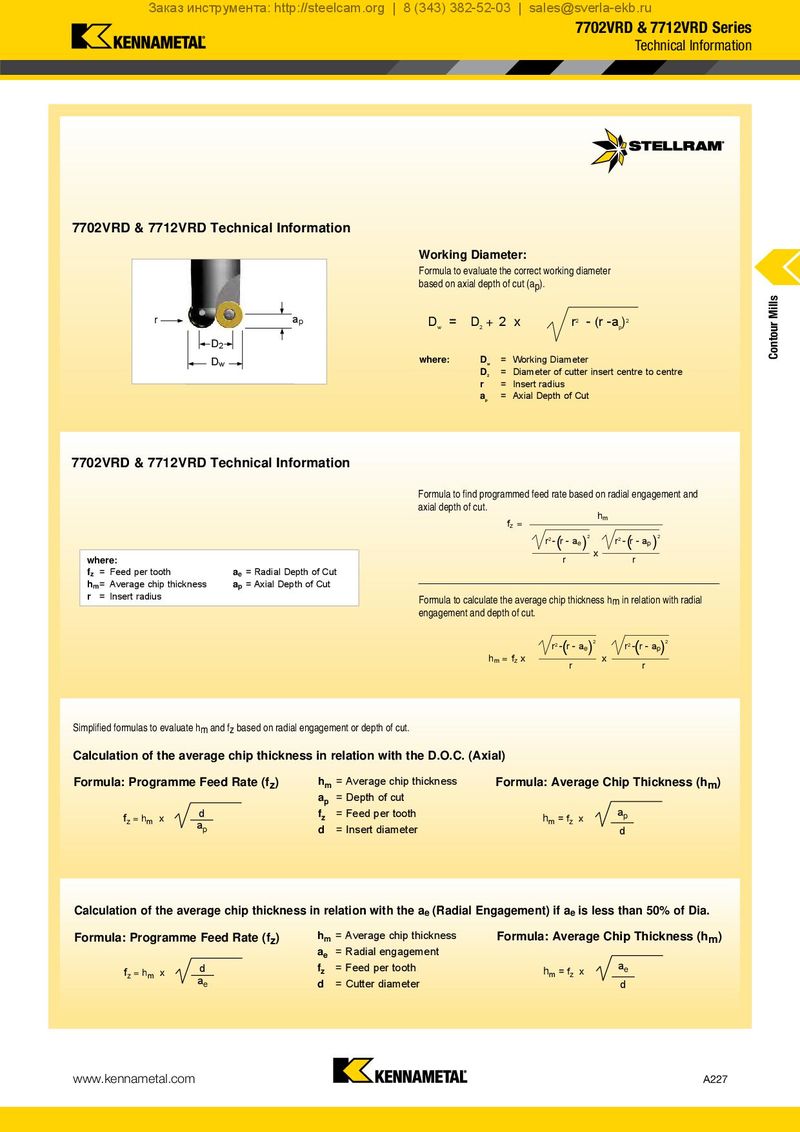

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 7702VRD & 7712VRD Series Technical Information 7702VRD & 7712VRD Technical Information Working Diameter: Formula to evaluate the correct working diameter based on axial depth of cut (ap). r ap Dw = D2 + 2 x r2 - (r -ap)2 Contour Mills D2 Dw where: D w = Working Diameter D2 = Diameter of cutter insert centre to centre r = Insert radius a p = Axial Depth of Cut 7702VRD & 7712VRD Technical Information Formula to find programmed feed rate based on radial engagement and axial depth of cut. hm fz = ( ) r2 -r - ae 2 ( ) r2 -r-ap 2 where: r x r fz = Feed per tooth ae = Radial Depth of Cut hm = Average chip thickness ap = Axial Depth of Cut r = Insert radius Formula to calculate the average chip thickness hm in relation with radial engagement and depth of cut. ( ) r2 - 2 ( ) r2 - 2 r - ae r - ap hm = fz x r x r Simplified formulas to evaluate hm and fz based on radial engagement or depth of cut. Calculation of the average chip thickness in relation with the D.O.C. (Axial) Formula: Programme Feed Rate (fz) hm = Average chip thickness Formula: Average Chip Thickness (hm) ap = Depth of cut fz = hm x d fz = Feed per tooth hm = fz x ap ap d = Insert diameter d Calculation of the average chip thickness in relation with the ae (Radial Engagement) if ae is less than 50% of Dia. Formula: Programme Feed Rate (fz) hm = Average chip thickness Formula: Average Chip Thickness (hm) ae = Radial engagement fz = hm x d fz = Feed per tooth hm = fz x ae ae d = Cutter diameter d www.kennametal.com A227

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы