Каталог Stellram фрез со сменными пластинами - страница 22

Навигация

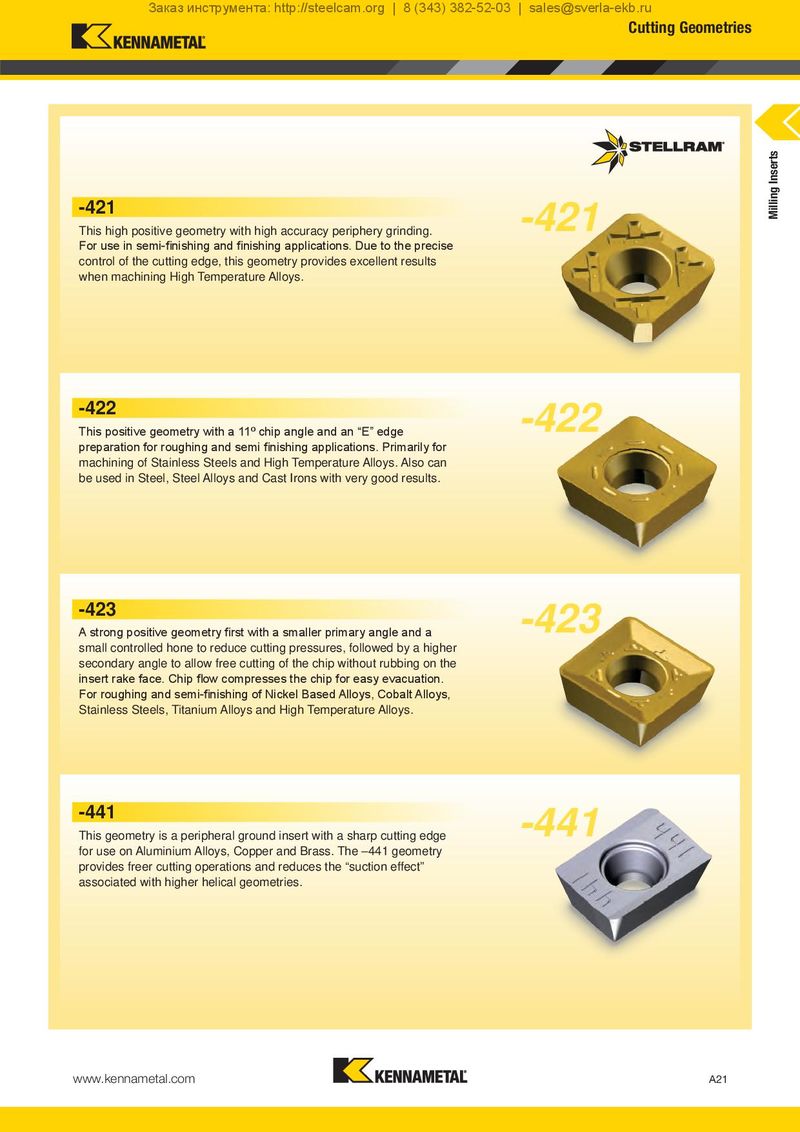

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru Cutting Geometries -421 -421 Milling Inserts This high positive geometry with high accuracy periphery grinding. For use in semi-finishing and finishing applications. Due to the precise control of the cutting edge, this geometry provides excellent results when machining High Temperature Alloys. -422 -422 This positive geometry with a 11º chip angle and an “E” edge preparation for roughing and semi finishing applications. Primarily for machining of Stainless Steels and High Temperature Alloys. Also can be used in Steel, Steel Alloys and Cast Irons with very good results. -423 -423 A strong positive geometry first with a smaller primary angle and a small controlled hone to reduce cutting pressures, followed by a higher secondary angle to allow free cutting of the chip without rubbing on the insert rake face. Chip flow compresses the chip for easy evacuation. For roughing and semi-finishing of Nickel Based Alloys, Cobalt Alloys, Stainless Steels, Titanium Alloys and High Temperature Alloys. -441 -441 This geometry is a peripheral ground insert with a sharp cutting edge for use on Aluminium Alloys, Copper and Brass. The –441 geometry provides freer cutting operations and reduces the “suction effect” associated with higher helical geometries. www.kennametal.com A21

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы