Каталог Stellram фрез со сменными пластинами - страница 21

Навигация

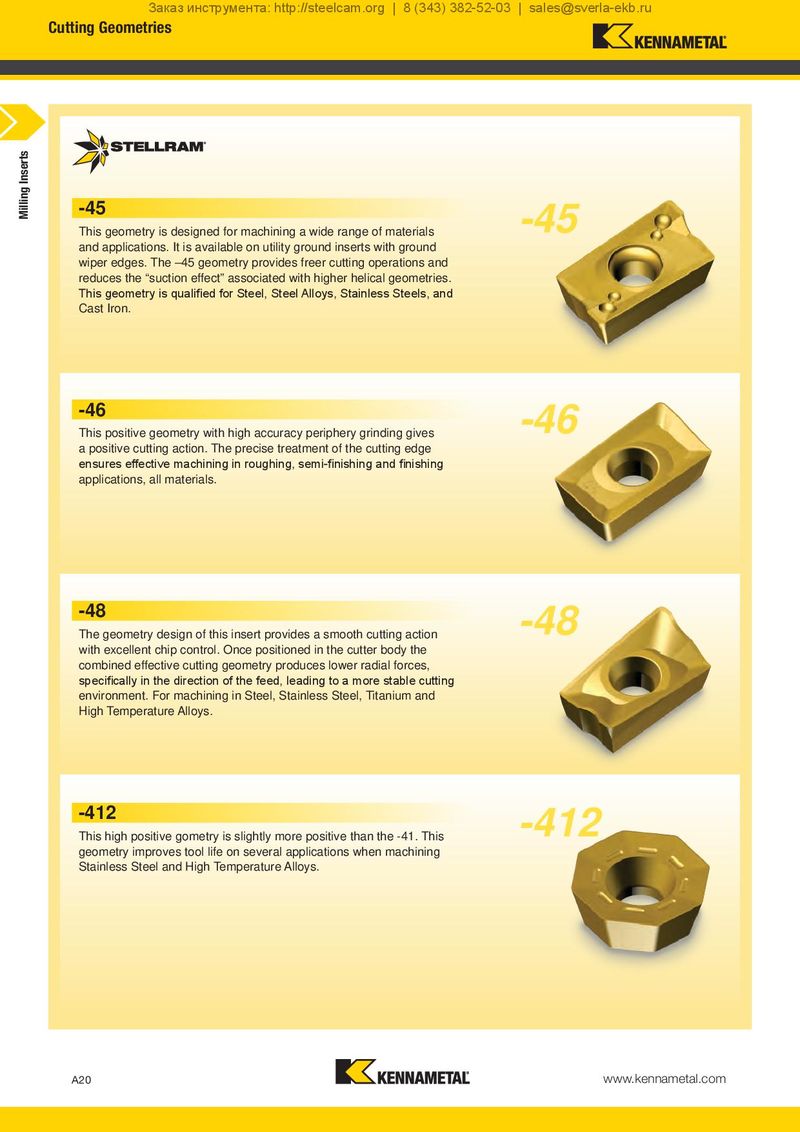

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru Cutting Geometries Milling Inserts -45 -45 This geometry is designed for machining a wide range of materials and applications. It is available on utility ground inserts with ground wiper edges. The –45 geometry provides freer cutting operations and reduces the “suction effect” associated with higher helical geometries. This geometry is qualified for Steel, Steel Alloys, Stainless Steels, and Cast Iron. -46 -46 This positive geometry with high accuracy periphery grinding gives a positive cutting action. The precise treatment of the cutting edge ensures effective machining in roughing, semi-finishing and finishing applications, all materials. -48 -48 The geometry design of this insert provides a smooth cutting action with excellent chip control. Once positioned in the cutter body the combined effective cutting geometry produces lower radial forces, specifically in the direction of the feed, leading to a more stable cutting environment. For machining in Steel, Stainless Steel, Titanium and High Temperature Alloys. -412 -412 This high positive gometry is slightly more positive than the -41. This geometry improves tool life on several applications when machining Stainless Steel and High Temperature Alloys. A20 www.kennametal.com

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы