Каталог Stellram фрез со сменными пластинами - страница 190

Навигация

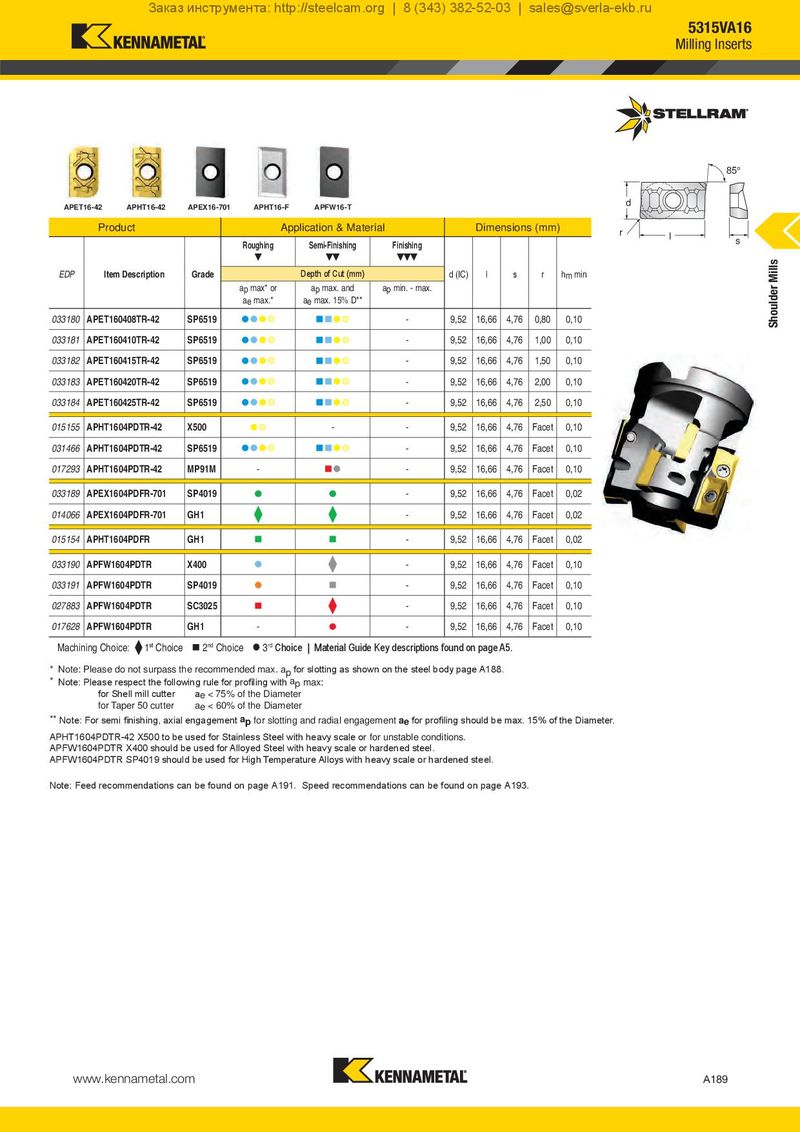

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 5315VA16 Milling Inserts 85° APET16-42 APHT16-42 APEX16-701 APHT16-F APFW16-T d Product Application & Material Dimensions (mm) r l Roughing Semi-Finishing Finishing s EDP Item Description Grade Depth of Cut (mm) d (IC) l s r hm min Shoulder Mills ap max* or ap max. and ap min. - max. ae max.* ae max. 15% D** 033180 APET160408TR-42 SP6519 - 9,52 16,66 4,76 0,80 0,10 033181 APET160410TR-42 SP6519 - 9,52 16,66 4,76 1,00 0,10 033182 APET160415TR-42 SP6519 - 9,52 16,66 4,76 1,50 0,10 033183 APET160420TR-42 SP6519 - 9,52 16,66 4,76 2,00 0,10 033184 APET160425TR-42 SP6519 - 9,52 16,66 4,76 2,50 0,10 015155 APHT1604PDTR-42 X500 - - 9,52 16,66 4,76 Facet 0,10 031466 APHT1604PDTR-42 SP6519 - 9,52 16,66 4,76 Facet 0,10 017293 APHT1604PDTR-42 MP91M - - 9,52 16,66 4,76 Facet 0,10 033189 APEX1604PDFR-701 SP4019 - 9,52 16,66 4,76 Facet 0,02 014066 APEX1604PDFR-701 GH1 - 9,52 16,66 4,76 Facet 0,02 015154 APHT1604PDFR GH1 - 9,52 16,66 4,76 Facet 0,02 033190 APFW1604PDTR X400 - 9,52 16,66 4,76 Facet 0,10 033191 APFW1604PDTR SP4019 - 9,52 16,66 4,76 Facet 0,10 027883 APFW1604PDTR SC3025 - 9,52 16,66 4,76 Facet 0,10 017628 APFW1604PDTR GH1 - - 9,52 16,66 4,76 Facet 0,10 Machining Choice: 1st Choice 2nd Choice 3rd Choice | Material Guide Key descriptions found on page A5. * Note: Please do not surpass the recommended max. ap for slotting as shown on the steel body page A188. * Note: Please respect the following rule for profiling with ap max: for Shell mill cutter ae < 75% of the Diameter for Taper 50 cutter ae < 60% of the Diameter ** Note: For semi finishing, axial engagement ap for slotting and radial engagement ae for profiling should be max. 15% of the Diameter. APHT1604PDTR-42 X500 to be used for Stainless Steel with heavy scale or for unstable conditions. APFW1604PDTR X400 should be used for Alloyed Steel with heavy scale or hardened steel. APFW1604PDTR SP4019 should be used for High Temperature Alloys with heavy scale or hardened steel. Note: Feed recommendations can be found on page A191. Speed recommendations can be found on page A193. www.kennametal.com A189

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы