Каталог Stellram фрез со сменными пластинами - страница 171

Навигация

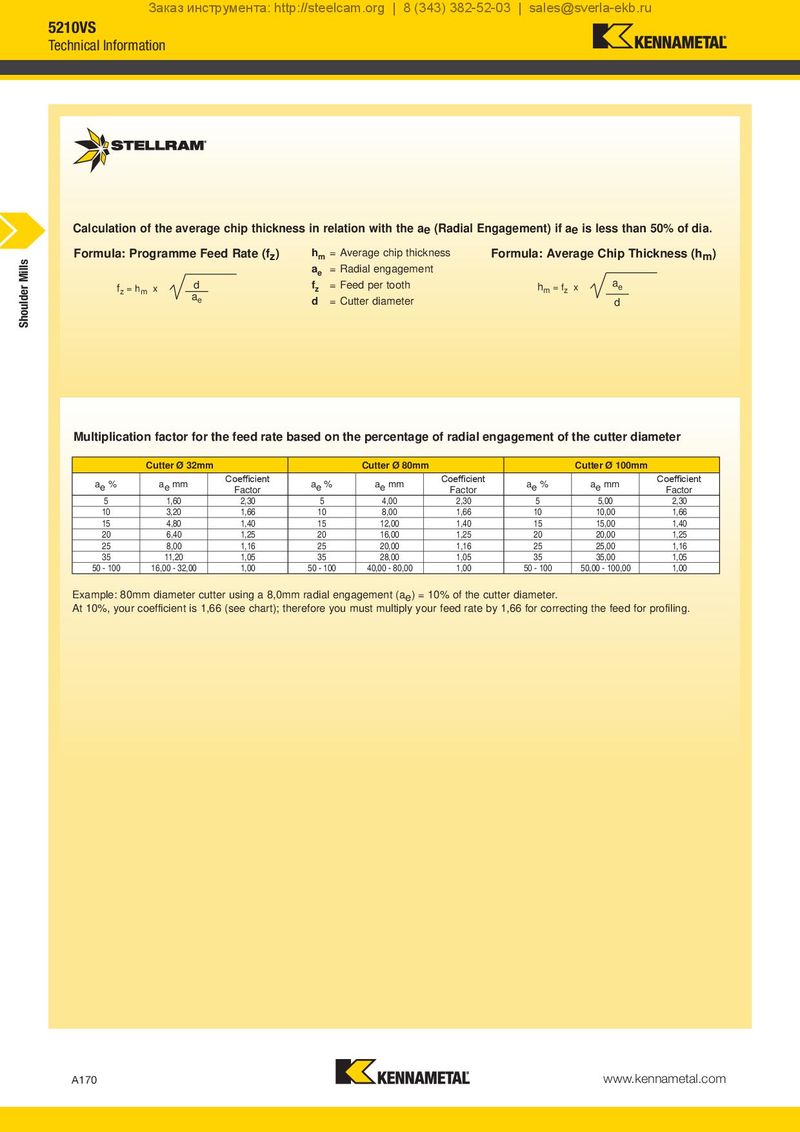

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 5210VS Technical Information Calculation of the average chip thickness in relation with the ae (Radial Engagement) if ae is less than 50% of dia. Shoulder Mills Formula: Programme Feed Rate (fz) hm = Average chip thickness Formula: Average Chip Thickness (hm) ae = Radial engagement fz = hm x d fz = Feed per tooth hm = fz x ae ae d = Cutter diameter d Multiplication factor for the feed rate based on the percentage of radial engagement of the cutter diameter Cutter Ø 32mm Cutter Ø 80mm Cutter Ø 100mm ae % ae mm Coefficient ae % ae mm Coefficient ae % ae mm Coefficient Factor Factor Factor 5 1,60 2,30 5 4,00 2,30 5 5,00 2,30 10 3,20 1,66 10 8,00 1,66 10 10,00 1,66 15 4,80 1,40 15 12,00 1,40 15 15,00 1,40 20 6,40 1,25 20 16,00 1,25 20 20,00 1,25 25 8,00 1,16 25 20,00 1,16 25 25,00 1,16 35 11,20 1,05 35 28,00 1,05 35 35,00 1,05 50 - 100 16,00 - 32,00 1,00 50 - 100 40,00 - 80,00 1,00 50 - 100 50,00 - 100,00 1,00 Example: 80mm diameter cutter using a 8,0mm radial engagement (ae) = 10% of the cutter diameter. At 10%, your coefficient is 1,66 (see chart); therefore you must multiply your feed rate by 1,66 for correcting the feed for profiling. A170 www.kennametal.com

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы