Каталог Stellram фрез со сменными пластинами - страница 155

Навигация

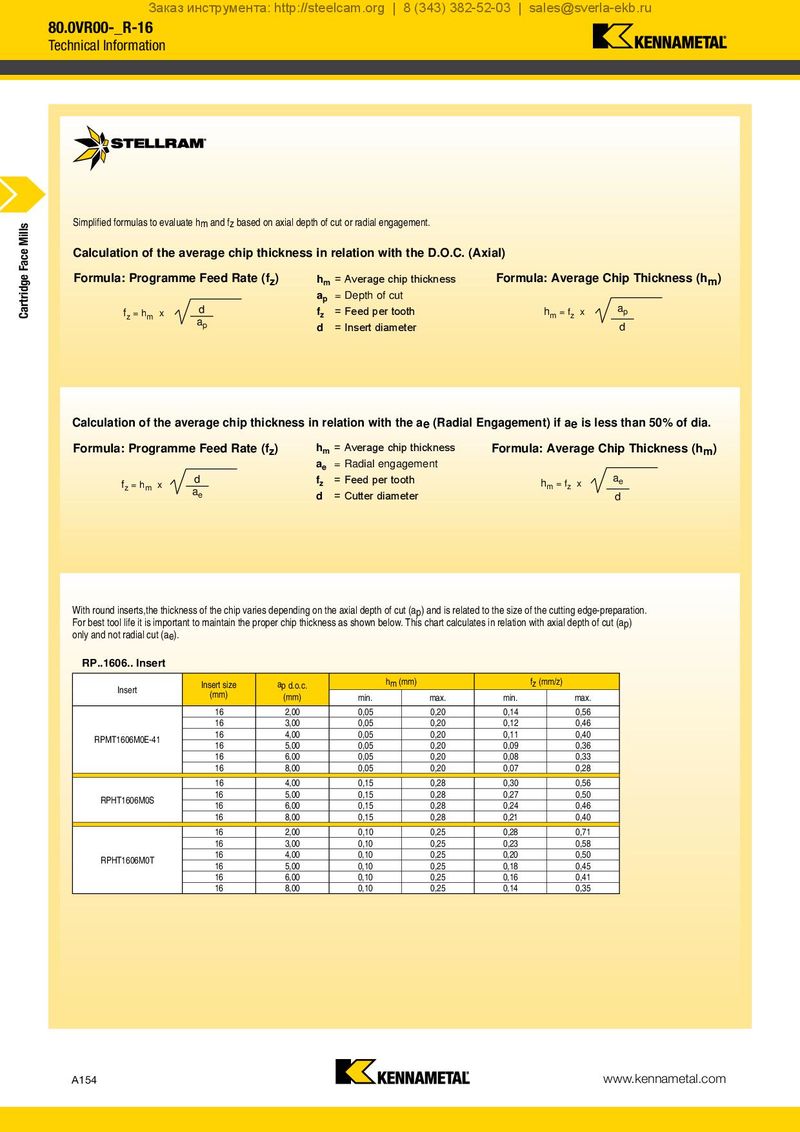

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 80.0VR00-_R-16 Technical Information Cartridge Face Mills Simplified formulas to evaluate hm and fz based on axial depth of cut or radial engagement. Calculation of the average chip thickness in relation with the D.O.C. (Axial) Formula: Programme Feed Rate (fz) hm = Average chip thickness Formula: Average Chip Thickness (hm) ap = Depth of cut fz = hm x d fz = Feed per tooth hm = fz x ap ap d = Insert diameter d Calculation of the average chip thickness in relation with the ae (Radial Engagement) if ae is less than 50% of dia. Formula: Programme Feed Rate (fz) hm = Average chip thickness Formula: Average Chip Thickness (hm) ae = Radial engagement fz = hm x d fz = Feed per tooth hm = fz x ae ae d = Cutter diameter d With round inserts,the thickness of the chip varies depending on the axial depth of cut (ap) and is related to the size of the cutting edge-preparation. For best tool life it is important to maintain the proper chip thickness as shown below. This chart calculates in relation with axial depth of cut (ap) only and not radial cut (ae). RP..1606.. Insert Insert Insert size ap d.o.c. hm (mm) fz (mm/z) (mm) (mm) min. max. min. max. 16 2,00 0,05 0,20 0,14 0,56 16 3,00 0,05 0,20 0,12 0,46 RPMT1606M0E-41 16 4,00 0,05 0,20 0,11 0,40 16 5,00 0,05 0,20 0,09 0,36 16 6,00 0,05 0,20 0,08 0,33 16 8,00 0,05 0,20 0,07 0,28 16 4,00 0,15 0,28 0,30 0,56 RPHT1606M0S 16 5,00 0,15 0,28 0,27 0,50 16 6,00 0,15 0,28 0,24 0,46 16 8,00 0,15 0,28 0,21 0,40 16 2,00 0,10 0,25 0,28 0,71 16 3,00 0,10 0,25 0,23 0,58 RPHT1606M0T 16 4,00 0,10 0,25 0,20 0,50 16 5,00 0,10 0,25 0,18 0,45 16 6,00 0,10 0,25 0,16 0,41 16 8,00 0,10 0,25 0,14 0,35 A154 www.kennametal.com

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы