Каталог Stellram фрез со сменными пластинами - страница 124

Навигация

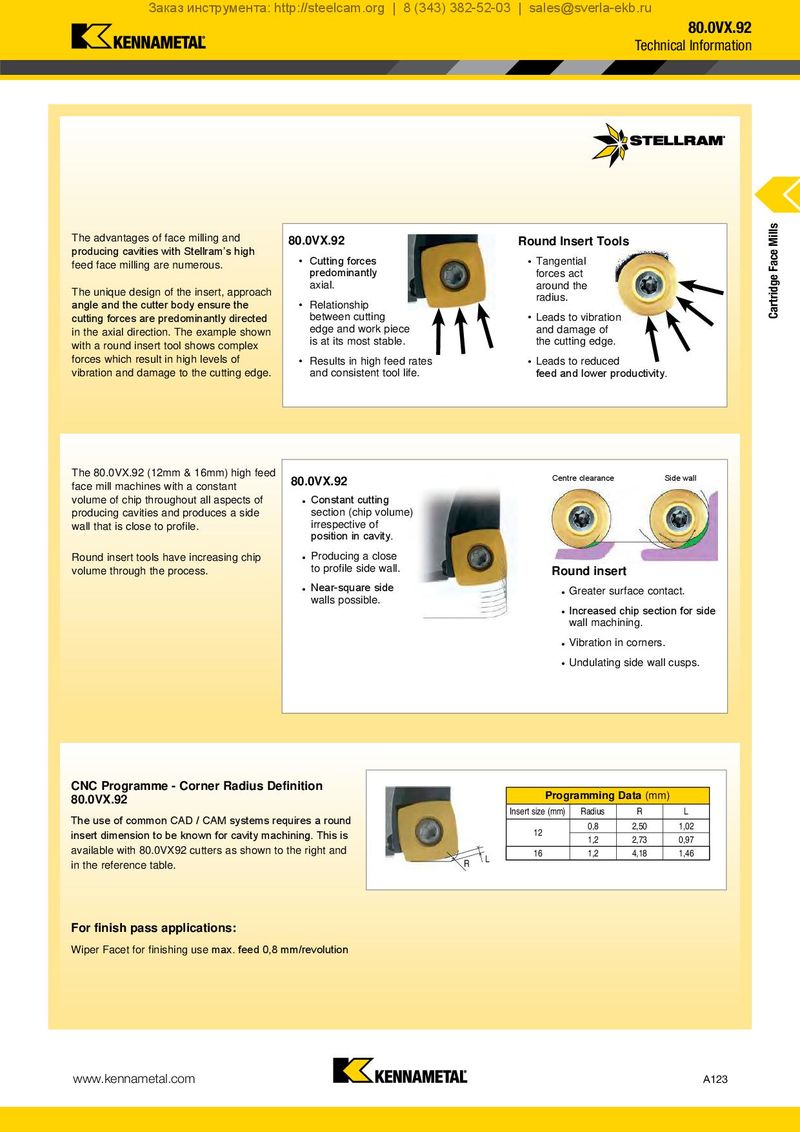

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 80.0VX.92 Technical Information The advantages of face milling and 80.0VX.92 Round Insert Tools Cartridge Face Mills producing cavities with Stellram’s high • Cutting forces • Tangential feed face milling are numerous. predominantly forces act The unique design of the insert, approach axial. around the angle and the cutter body ensure the • Relationship radius. cutting forces are predominantly directed between cutting • Leads to vibration in the axial direction. The example shown edge and work piece and damage of with a round insert tool shows complex is at its most stable. the cutting edge. forces which result in high levels of • Results in high feed rates • Leads to reduced vibration and damage to the cutting edge. and consistent tool life. feed and lower productivity. The 80.0VX.92 (12mm & 16mm) high feed 80.0VX.92 Centre clearance Side wall face mill machines with a constant volume of chip throughout all aspects of • Constant cutting producing cavities and produces a side section (chip volume) wall that is close to profile. irrespective of position in cavity. Round insert tools have increasing chip • Producing a close volume through the process. to profile side wall. Round insert • Near-square side • Greater surface contact. walls possible. • Increased chip section for side wall machining. • Vibration in corners. • Undulating side wall cusps. CNC Programme - Corner Radius Definition Programming Data (mm) 80.0VX.92 The use of common CAD / CAM systems requires a round Insert size (mm) Radius R L insert dimension to be known for cavity machining. This is 12 0,8 2,50 1,02 1,2 2,73 0,97 available with 80.0VX92 cutters as shown to the right and L 16 1,2 4,18 1,46 in the reference table. R For finish pass applications: Wiper Facet for finishing use max. feed 0,8 mm/revolution www.kennametal.com A123

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы