Каталог Stellram фрез со сменными пластинами - страница 109

Навигация

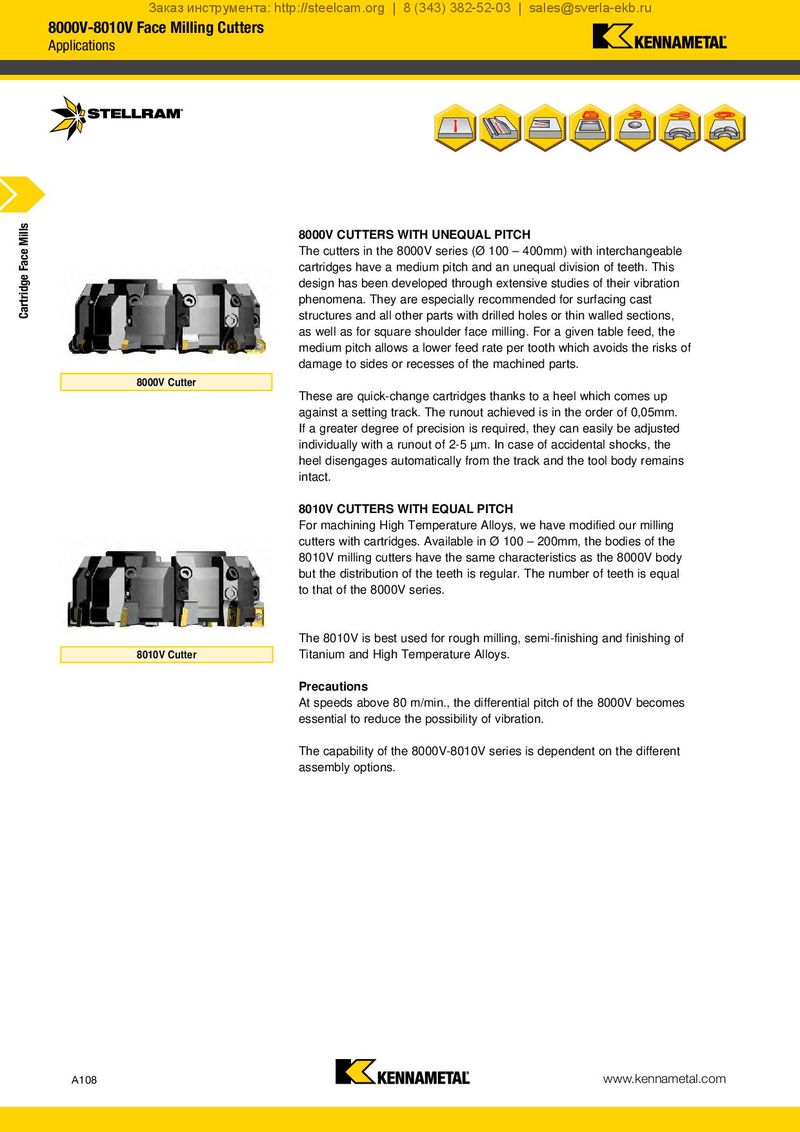

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 8000V-8010V Face Milling Cutters Applications Cartridge Face Mills 8000V CUTTERS WITH UNEQUAL PITCH The cutters in the 8000V series (Ø 100 – 400mm) with interchangeable cartridges have a medium pitch and an unequal division of teeth. This design has been developed through extensive studies of their vibration phenomena. They are especially recommended for surfacing cast structures and all other parts with drilled holes or thin walled sections, as well as for square shoulder face milling. For a given table feed, the medium pitch allows a lower feed rate per tooth which avoids the risks of damage to sides or recesses of the machined parts. 8000V Cutter These are quick-change cartridges thanks to a heel which comes up against a setting track. The runout achieved is in the order of 0,05mm. If a greater degree of precision is required, they can easily be adjusted individually with a runout of 2-5 µm. In case of accidental shocks, the heel disengages automatically from the track and the tool body remains intact. 8010V CUTTERS WITH EQUAL PITCH For machining High Temperature Alloys, we have modified our milling cutters with cartridges. Available in Ø 100 – 200mm, the bodies of the 8010V milling cutters have the same characteristics as the 8000V body but the distribution of the teeth is regular. The number of teeth is equal to that of the 8000V series. The 8010V is best used for rough milling, semi-finishing and finishing of 8010V Cutter Titanium and High Temperature Alloys. Precautions At speeds above 80 m/min., the differential pitch of the 8000V becomes essential to reduce the possibility of vibration. The capability of the 8000V-8010V series is dependent on the different assembly options. A108 www.kennametal.com

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы