Общий каталог SGS 2018 - страница 350

Навигация

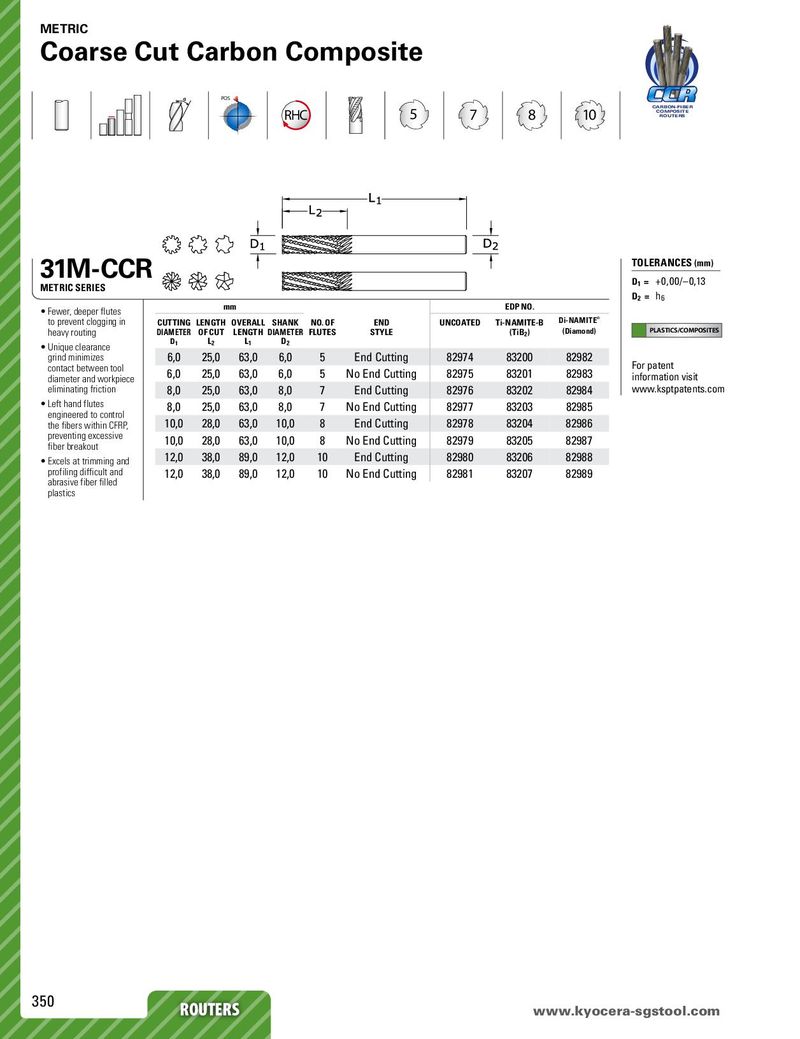

METRIC Coarse Cut Carbon Composite POS CCR CARBON-FIBER RHC 5 7 8 10 COMPOSITE ROUTERS 31M-CCR TOLERANCES (mm) METRIC SERIES D1 = +0,00/–0,13 D2 = h6 • Fewer, deeper flutes mm EDP NO. to prevent clogging in CUTTING LENGTH OVERALL SHANK NO. OF END UNCOATED Ti-NAMITE-B Di-NAMITE® heavy routing DIAMETER OF CUT LENGTH DIAMETER FLUTES STYLE (TiB2) (Diamond) PLASTICS/COMPOSITES • Unique clearance D1 L2 L1 D2 grind minimizes 6,0 25,0 63,0 6,0 5 End Cutting 82974 83200 82982 For patent contact between tool 6,0 25,0 63,0 6,0 5 No End Cutting 82975 83201 82983 information visit diameter and workpiece eliminating friction 8,0 25,0 63,0 8,0 7 End Cutting 82976 83202 82984 www.ksptpatents.com • Left hand flutes 8,0 25,0 63,0 8,0 7 No End Cutting 82977 83203 82985 engineered to control 10,0 28,0 63,0 10,0 8 End Cutting 82978 83204 82986 the fibers within CFRP, preventing excessive 10,0 28,0 63,0 10,0 8 No End Cutting 82979 83205 82987 fiber breakout • Excels at trimming and 12,0 38,0 89,0 12,0 10 End Cutting 82980 83206 82988 profiling difficult and 12,0 38,0 89,0 12,0 10 No End Cutting 82981 83207 82989 abrasive fiber filled plastics 350 ROUTERS www.RkOyUocTEeRraS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском