Общий каталог SGS 2018 - страница 347

Навигация

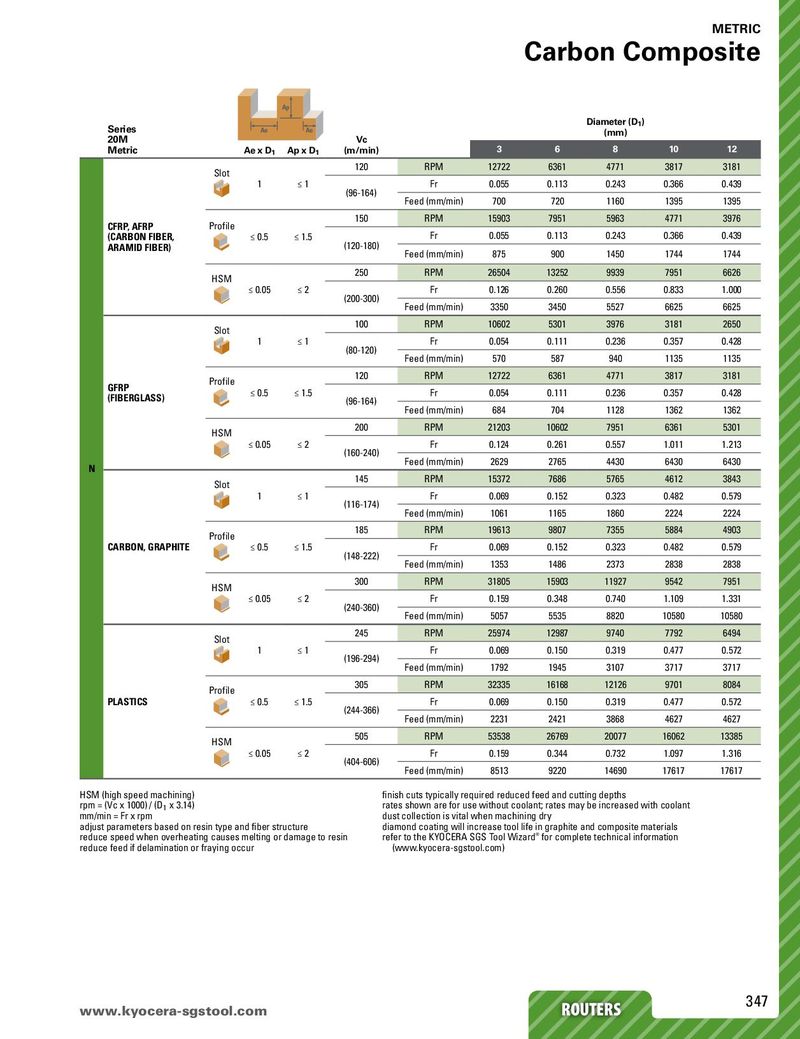

METRIC Carbon Composite Ap Series Diameter (D1) Ae Ae (mm) 20M Vc Metric Ae x D1 Ap x D1 (m/min) 3 6 8 10 12 Slot 120 RPM 12722 6361 4771 3817 3181 1 ≤1 (96-164) Fr 0.055 0.113 0.243 0.366 0.439 Feed (mm/min) 700 720 1160 1395 1395 CFRP, AFRP Profile 150 RPM 15903 7951 5963 4771 3976 (CARBON FIBER, ≤ 0.5 ≤ 1.5 Fr 0.055 0.113 0.243 0.366 0.439 ARAMID FIBER) (120-180) Feed (mm/min) 875 900 1450 1744 1744 HSM 250 RPM 26504 13252 9939 7951 6626 ≤ 0.05 ≤2 (200-300) Fr 0.126 0.260 0.556 0.833 1.000 Feed (mm/min) 3350 3450 5527 6625 6625 Slot 100 RPM 10602 5301 3976 3181 2650 1 ≤1 (80-120) Fr 0.054 0.111 0.236 0.357 0.428 Feed (mm/min) 570 587 940 1135 1135 Profile 120 RPM 12722 6361 4771 3817 3181 GFRP ≤ 0.5 ≤ 1.5 Fr 0.054 0.111 0.236 0.357 0.428 (FIBERGLASS) (96-164) Feed (mm/min) 684 704 1128 1362 1362 HSM 200 RPM 21203 10602 7951 6361 5301 ≤ 0.05 ≤2 (160-240) Fr 0.124 0.261 0.557 1.011 1.213 N Feed (mm/min) 2629 2765 4430 6430 6430 Slot 145 RPM 15372 7686 5765 4612 3843 1 ≤1 (116-174) Fr 0.069 0.152 0.323 0.482 0.579 Feed (mm/min) 1061 1165 1860 2224 2224 Profile 185 RPM 19613 9807 7355 5884 4903 CARBON, GRAPHITE ≤ 0.5 ≤ 1.5 (148-222) Fr 0.069 0.152 0.323 0.482 0.579 Feed (mm/min) 1353 1486 2373 2838 2838 HSM 300 RPM 31805 15903 11927 9542 7951 ≤ 0.05 ≤2 (240-360) Fr 0.159 0.348 0.740 1.109 1.331 Feed (mm/min) 5057 5535 8820 10580 10580 Slot 245 RPM 25974 12987 9740 7792 6494 1 ≤1 (196-294) Fr 0.069 0.150 0.319 0.477 0.572 Feed (mm/min) 1792 1945 3107 3717 3717 Profile 305 RPM 32335 16168 12126 9701 8084 PLASTICS ≤ 0.5 ≤ 1.5 (244-366) Fr 0.069 0.150 0.319 0.477 0.572 Feed (mm/min) 2231 2421 3868 4627 4627 HSM 505 RPM 53538 26769 20077 16062 13385 ≤ 0.05 ≤2 (404-606) Fr 0.159 0.344 0.732 1.097 1.316 Feed (mm/min) 8513 9220 14690 17617 17617 HSM (high speed machining) finish cuts typically required reduced feed and cutting depths rpm = (Vc x 1000) / (D1 x 3.14) rates shown are for use without coolant; rates may be increased with coolant mm/min = Fr x rpm dust collection is vital when machining dry adjust parameters based on resin type and fiber structure diamond coating will increase tool life in graphite and composite materials reduce speed when overheating causes melting or damage to resin refer to the KYOCERA SGS Tool Wizard® for complete technical information reduce feed if delamination or fraying occur (www.kyocera-sgstool.com) www.kyocerRaO-sUgTsEtRoSol.com ROUTERS 347

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском