Общий каталог SGS 2018 - страница 345

Навигация

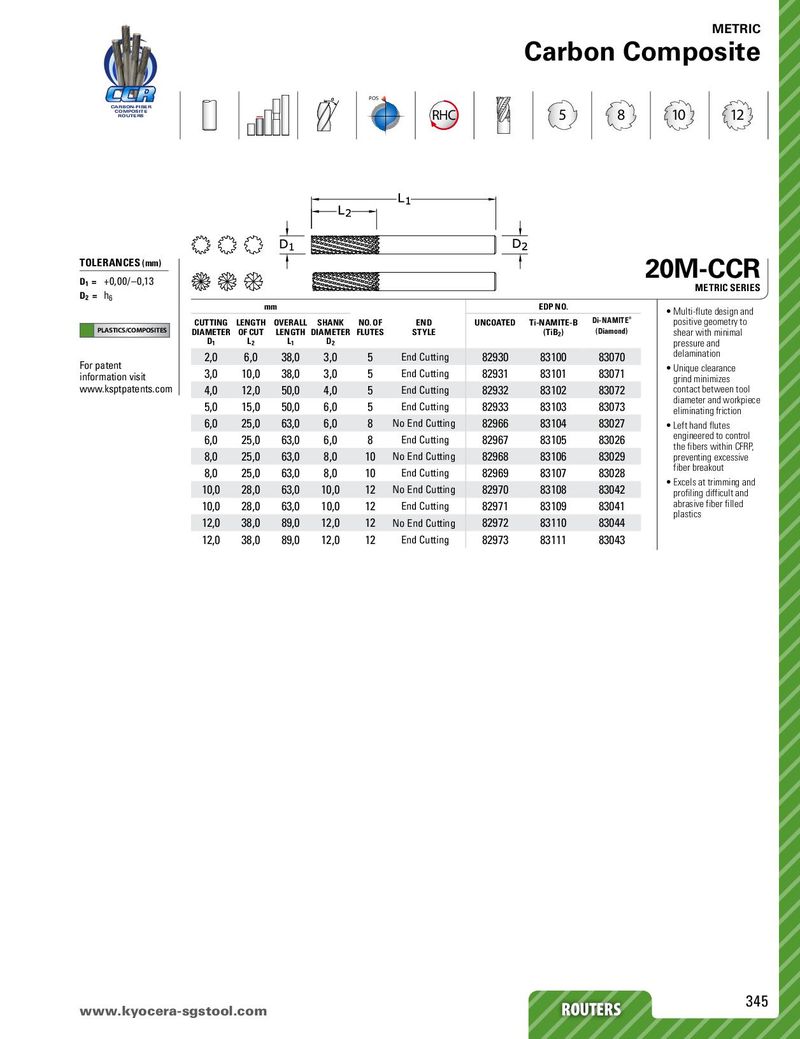

METRIC Carbon Composite CCR POS CARBON-FIBER COMPOSITE RHC 5 8 10 12 ROUTERS TOLERANCES (mm) 20M-CCR D1 = +0,00/–0,13 METRIC SERIES D2 = h6 mm EDP NO. • Multi-flute design and CUTTING LENGTH OVERALL SHANK NO. OF END UNCOATED Ti-NAMITE-B Di-NAMITE® positive geometry to PLASTICS/COMPOSITES DIAMETER OF CUT LENGTH DIAMETER FLUTES STYLE (TiB2) (Diamond) shear with minimal D1 L2 L1 D2 pressure and 2,0 6,0 38,0 3,0 5 End Cutting 82930 83100 83070 delamination For patent 3,0 10,0 38,0 3,0 5 End Cutting 82931 83101 83071 • Unique clearance information visit grind minimizes www.ksptpatents.com 4,0 12,0 50,0 4,0 5 End Cutting 82932 83102 83072 contact between tool 5,0 15,0 50,0 6,0 5 End Cutting 82933 83103 83073 diameter and workpiece eliminating friction 6,0 25,0 63,0 6,0 8 No End Cutting 82966 83104 83027 • Left hand flutes 6,0 25,0 63,0 6,0 8 End Cutting 82967 83105 83026 engineered to control the fibers within CFRP, 8,0 25,0 63,0 8,0 10 No End Cutting 82968 83106 83029 preventing excessive 8,0 25,0 63,0 8,0 10 End Cutting 82969 83107 83028 fiber breakout 10,0 28,0 63,0 10,0 12 No End Cutting 82970 83108 83042 • Excels at trimming and profiling difficult and 10,0 28,0 63,0 10,0 12 End Cutting 82971 83109 83041 abrasive fiber filled 12,0 38,0 89,0 12,0 12 No End Cutting 82972 83110 83044 plastics 12,0 38,0 89,0 12,0 12 End Cutting 82973 83111 83043 www.kyocerRaO-sUgTsEtRoSol.com ROUTERS 345

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском