Каталог SGS фрезы для обработки пластика PCR series - страница 2

Навигация

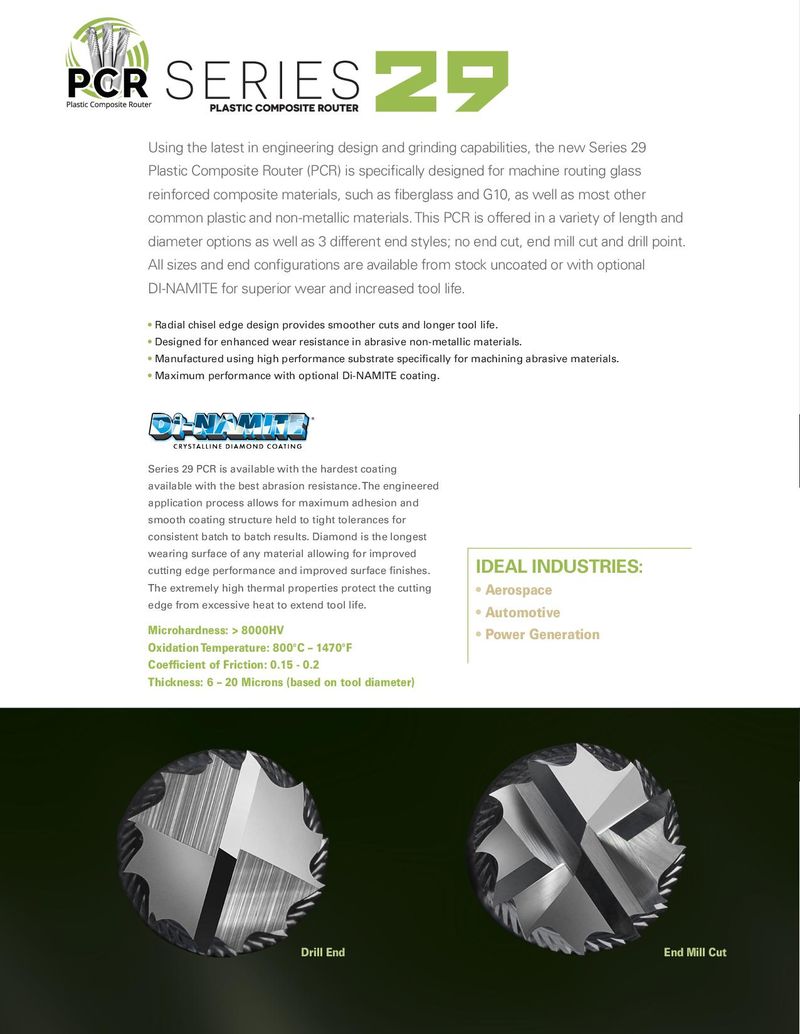

Using the latest in engineering design and grinding capabilities, the new Series 29 Plastic Composite Router (PCR) is specifically designed for machine routing glass reinforced composite materials, such as fiberglass and G10, as well as most other common plastic and non-metallic materials. This PCR is offered in a variety of length and diameter options as well as 3 different end styles; no end cut, end mill cut and drill point. All sizes and end configurations are available from stock uncoated or with optional DI-NAMITE for superior wear and increased tool life. • Radial chisel edge design provides smoother cuts and longer tool life. • Designed for enhanced wear resistance in abrasive non-metallic materials. • Manufactured using high performance substrate specifically for machining abrasive materials. • Maximum performance with optional Di-NAMITE coating. Series 29 PCR is available with the hardest coating available with the best abrasion resistance. The engineered application process allows for maximum adhesion and smooth coating structure held to tight tolerances for consistent batch to batch results. Diamond is the longest wearing surface of any material allowing for improved cutting edge performance and improved surface finishes. Ideal Industries: The extremely high thermal properties protect the cutting • Aerospace edge from excessive heat to extend tool life. • Automotive Microhardness: > 8000HV • Power Generation Oxidation Temperature: 800°C – 1470°F Coefficient of Friction: 0.15 - 0.2 Thickness: 6 – 20 Microns (based on tool diameter) Drill End End Mill Cut

Каталог SGS инструмент для сверления

Каталог SGS инструмент для сверления Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS фрезы с переменным углом спирали Z-carb

Каталог SGS фрезы с переменным углом спирали Z-carb