Каталог SGS монолитный инструмент из композитных материалов - страница 5

Навигация

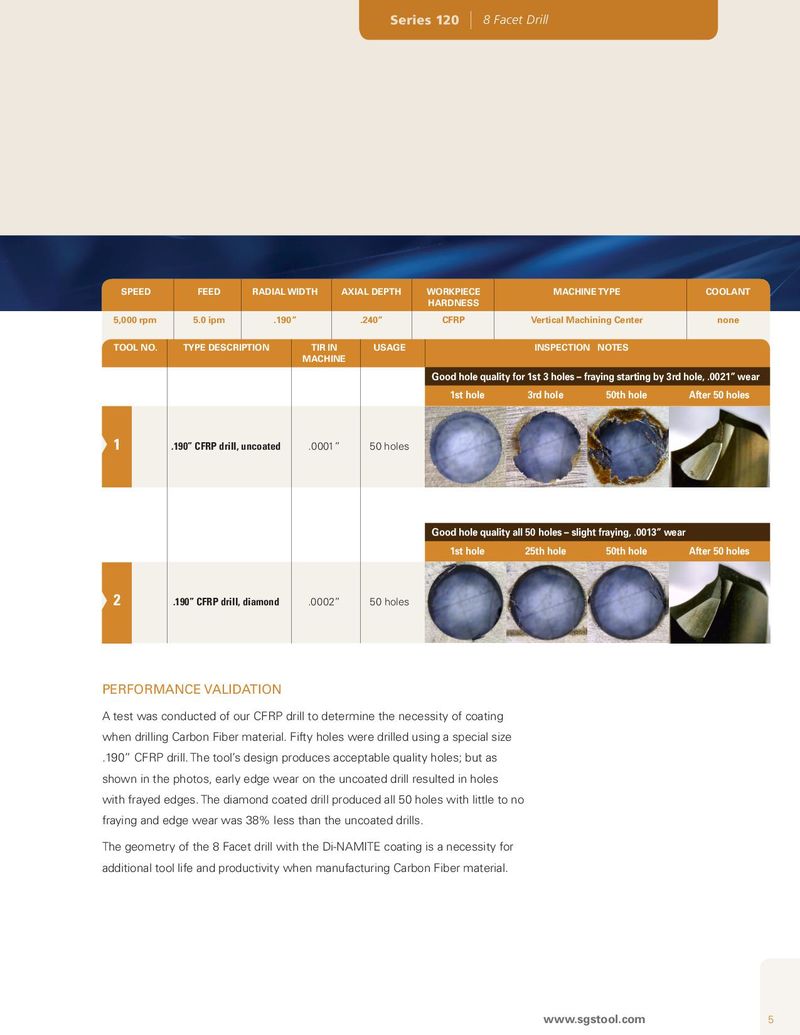

Series 120 8 Facet Drill SPEED FEED RADIAL WIDTH AXIAL DEPTH WORKPIECE MACHINE TYPE COOLANT HARDNESS 5,000 rpm 5.0 ipm .190” .240” CFRP Vertical Machining Center none TOOL NO. TYPE DESCRIPTION TIR IN USAGE INSPECTION NOTES MACHINE Good hole quality for 1st 3 holes – fraying starting by 3rd hole, .0021” wear 1st hole 3rd hole 50th hole After 50 holes 1 .190” CFRP drill, uncoated .0001” 50 holes Good hole quality all 50 holes – slight fraying, .0013” wear 1st hole 25th hole 50th hole After 50 holes 2 .190” CFRP drill, diamond .0002” 50 holes PERFORMANCE VALIDATION A test was conducted of our CFRP drill to determine the necessity of coating when drilling Carbon Fiber material. Fifty holes were drilled using a special size .190” CFRP drill. The tool’s design produces acceptable quality holes; but as shown in the photos, early edge wear on the uncoated drill resulted in holes with frayed edges. The diamond coated drill produced all 50 holes with little to no fraying and edge wear was 38% less than the uncoated drills. The geometry of the 8 Facet drill with the Di-NAMITE coating is a necessity for additional tool life and productivity when manufacturing Carbon Fiber material. www.sgstool.com 5

Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS микроинструмент

Каталог SGS микроинструмент Общий каталог SGS 2021

Общий каталог SGS 2021 Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series