Общий каталог PRECITOOL - страница 458

Навигация

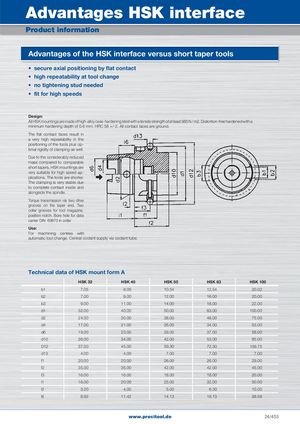

Advantages HSK interface QPruoicdkucotvienrfvoiremwaftoiorneasy ordering Advantages of the HSK interface versus short taper tools • secure axial positioning by flat contact • high repeatability at tool change • no tightening stud needed • fit for high speeds Design: All HSK mountings are made of high-alloy case-hardening steel with a tensile strength of at least 985 N / m2. Distortion-free hardened with a minimum hardening depth of 0.6 mm. HRC 58 +/-2. All contact faces are ground. The flat contact faces result in a very high repeatability in the positioning of the tools plus op- timal rigidity of clamping as well. Due to the considerably reduced mass compared to comparable short tapers, HSK mountings are very suitable for high speed ap- plications. The tools are shorter. The clamping is very stable due to complete contact inside and alongside the spindle. Torque transmission via two drive grooves on the taper end. Two collar grooves for tool magazine, position notch. Bore hole for data carrier DIN 69873 in collar Use: For machining centres with automatic tool change. Central coolant supply via coolant tube. Technical data of HSK mount form A HSK 32 HSK 40 HSK 50 HSK 63 HSK 100 b1 7.05 8.05 10.54 12.54 20.02 b2 7.00 9.00 12.00 16.00 20.00 b3 9.00 11.00 14.00 18.00 22.00 d1 32.00 40.00 50.00 63.00 100.00 d2 24.00 30.00 38.00 48.00 75.00 d4 17.00 21.00 26.00 34.00 53.00 d6 19.00 23.00 29.00 37.00 58.00 d10 26.00 34.00 42.00 53.00 85.00 D12 37.00 45.00 59.30 72.30 109.75 d13 4.00 4.00 7.00 7.00 7.00 f1 20.00 20.00 26.00 26.00 29.00 f2 35.00 35.00 42.00 42.00 45.00 f3 16.00 16.00 18.00 18.00 20.00 l1 16.00 20.00 25.00 32.00 50.00 l2 3.20 4.00 5.00 6.30 10.00 l6 8.92 11.42 14.13 18.13 28.56 www.precitool.de 24/453