Общий каталог OSG 2018 - 2019 - страница 991

Навигация

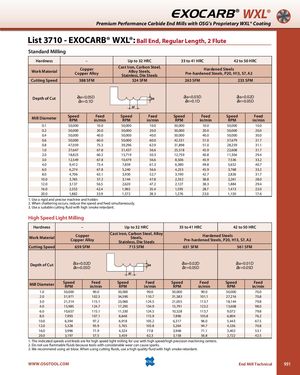

EXOCARB® WXL® Premium Performance Carbide End Mills with OSG’s Proprietary WXL® Coating List 3710 - EXOCARB® WXL®: Ball End, Regular Length, 2 Flute Standard Milling Hardness – Up to 32 HRC 33 to 41 HRC 42 to 50 HRC Work Material CopperCopper Alloy Cast Iron, Carbon Steel,Alloy Steels,Stainless, Die SteelsHardened SteelsPre-hardened Steels, P20, H13, S7, A2 Cutting Speed 388 SFM 324 SFM 263 SFM 233 SFM Depth of Cut aa=0.05Dar=0.1D aa=0.03D aa=0.02Dar=0.1Dar=0.05D Mill Diameter SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min 0.1 50,000 10.0 50,000 10.0 50,000 10.0 50,000 10.0 0.2 50,000 20.0 50,000 20.0 50,000 20.0 50,000 20.0 0.4 50,000 40.0 50,000 40.0 50,000 40.0 50,000 30.0 0.6 50,000 60.0 50,000 60.0 42,531 51.0 37,679 31.7 0.8 47,059 75.3 39,296 62.9 31,898 51.0 28,259 31.1 1.0 37,647 67.8 31,437 56.6 25,518 45.9 22,608 31.7 2.0 18,823 60.2 15,719 50.3 12,759 40.8 11,304 29.4 3.0 12,549 67.8 10,479 56.6 8,506 45.9 7,536 33.2 4.0 9,412 73.4 7,859 61.3 6,380 49.8 5,652 40.7 6.0 6,274 67.8 5,240 56.6 4,253 45.9 3,768 33.2 8.0 4,706 63.1 3,930 52.7 3,190 42.7 2,826 31.7 10.0 3,765 57.2 3,144 47.8 2,552 38.8 2,261 28.0 12.0 3,137 56.5 2,620 47.2 2,127 38.3 1,884 29.4 16.0 2,353 42.4 1,965 35.4 1,595 28.7 1,413 22.0 20.0 1,882 33.9 1,572 28.3 1,276 23.0 1,130 17.6 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. High Speed Light Milling Hardness – Up to 32 HRC 33 to 41 HRC 42 to 50 HRC Work Material CopperCopper Alloy Cast Iron, Carbon Steel, AlloySteels,Stainless, Die Steels Hardened SteelsPre-hardened Steels, P20, H13, S7, A2 Cutting Speed 659 SFM 713 SFM 651 SFM 561 SFM Depth of Cut aa=0.02Dar=0.05D aa=0.02D aa=0.01Dar=0.05Dar=0.05D Mill Diameter SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min 1.0 50,000 90.0 50,000 90.0 50,000 90.0 50,000 70.0 2.0 31,971 102.3 34,590 110.7 31,583 101.1 27,216 70.8 3.0 21,314 115.1 23,060 124.5 21,055 113.7 18,144 79.8 4.0 15,985 124.7 17,295 134.9 15,791 123.2 13,608 98.0 6.0 10,657 115.1 11,530 124.5 10,528 113.7 9,072 79.8 8.0 7,993 107.1 8,648 115.9 7,896 105.8 6,804 76.2 10.0 6,394 97.2 6,918 105.2 6,317 96.0 5,443 67.5 12.0 5,328 95.9 5,765 103.8 5,264 94.7 4,536 70.8 16.0 3,996 71.9 4,324 77.8 3,948 71.1 3,402 53.1 20.0 3,197 57.5 3,459 62.3 3,158 56.8 2,722 42.5 1. The indicated speeds and feeds are for high speed light milling for use with high speed/high precision machining centers. 2. Do not use flammable fluids because tools with considerable wear can cause sparks. 3. We recommend using air blow. When using cutting fluids, use a high quality fluid with high smoke retardant. WWW.OSGTOOL.COM End Mill Technical 991

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta