Общий каталог OSG 2018 - 2019 - страница 990

Навигация

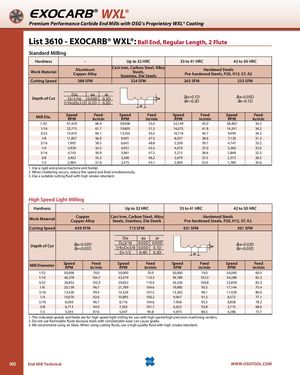

EXOCARB® WXL® Premium Performance Carbide End Mills with OSG’s Proprietary WXL® Coating List 3610 - EXOCARB® WXL®: Ball End, Regular Length, 2 Flute Standard Milling Hardness – Up to 32 HRC 33 to 41 HRC 42 to 50 HRC Work Material AluminumCopper Alloy Cast Iron, Carbon Steel, AlloySteels,Stainless, Die Steels Hardened SteelsPre-hardened Steels, P20, H13, S7, A2 Cutting Speed 388 SFM 324 SFM 263 SFM 233 SFM Dia aa arDepth of CutD<1/160.05D0.2D1/16≤D≤1/20.1D0.2D aa=0.1D aa=0.05Dar=0.2Dar=0.1D Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min 1/32 47,429 66.4 39,606 55.4 32,149 45.0 28,482 34.2 1/16 23,715 61.7 19,803 51.5 16,075 41.8 14,241 34.2 3/32 15,810 60.1 13,202 50.2 10,716 40.7 9,494 34.2 1/8 11,857 56.9 9,901 47.5 8,037 38.6 7,120 31.3 3/16 7,905 58.5 6,601 48.8 5,358 39.7 4,747 33.2 1/4 5,929 54.5 4,951 45.5 4,019 37.0 3,560 32.0 5/16 4,743 56.9 3,961 47.5 3,215 38.6 2,848 32.5 3/8 3,952 55.3 3,300 46.2 2,679 37.5 2,373 28.5 1/2 2,964 51.6 2,475 43.1 2,009 35.0 1,780 30.6 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. High Speed Light Milling Hardness – Up to 32 HRC 33 to 41 HRC 42 to 50 HRC Work Material CopperCopper Alloy Cast Iron, Carbon Steel, AlloySteels, Stainless, Die Steels Hardened SteelsPre-hardened Steels, P20, H13, S7, A2 Cutting Speed 659 SFM 713 SFM 651 SFM 561 SFM Dia aa ar Depth of Cut aa=0.02Dar=0.05D D<3/16 0.02D 0.05D1/4≤D≤3/80.05D0.1D aa=0.02Dar=0.05D D=1/2 0.4D 0.2D Mill Diameter SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min 1/32 50,000 70.0 50,000 70.0 50,000 70.0 50,000 60.0 1/16 40,278 104.7 43,579 113.3 39,789 103.5 34,288 82.3 3/32 26,852 102.0 29,052 110.4 26,526 100.8 22,859 82.3 1/8 20,139 96.7 21,789 104.6 19,895 95.5 17,144 75.4 3/16 13,426 99.4 14,526 107.5 13,263 98.1 11,429 80.0 1/4 10,070 92.6 10,895 100.2 9,947 91.5 8,572 77.1 5/16 8,056 96.7 8,716 104.6 7,958 95.5 6,858 78.2 3/8 6,713 94.0 7,263 101.7 6,632 92.8 5,715 68.6 1/2 5,035 87.6 5,447 94.8 4,974 86.5 4,286 73.7 1. The indicated speeds and feeds are for high speed light milling for use with high speed/high precision machining centers. 2. Do not use flammable fluids because tools with considerable wear can cause sparks. 3. We recommend using air blow. When using cutting fluids, use a high quality fluid with high smoke retardant. 990 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta