Общий каталог OSG 2018 - 2019 - страница 977

Навигация

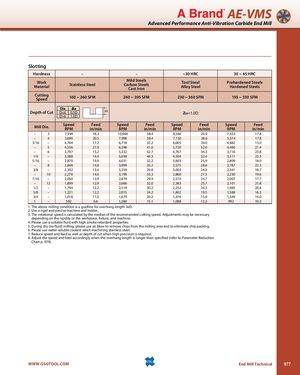

AE-VMS Advanced Performance Anti-Vibration Carbide End Mill Slotting Hardness – – ~30 HRC 30 ~ 45 HRC WorkMaterial Stainless Steel Mild SteelsCarbon SteelsCast Iron Tool Steel Prehardened SteelsAlloy SteelHardened Steels CuttingSpeed 160 ~ 260 SFM 260 ~ 395 SFM 230 ~ 360 SFM 195 ~ 330 SFM Dia aa Depth of Cut D≤6 0.5D aa=1.0D D>6 1.0D Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min – 3 7,594 18.2 10,664 38.4 8,564 24.0 7,433 17.8 – 4 5,696 20.5 7,998 38.4 7,150 28.6 5,574 17.8 3/16 – 4,784 17.2 6,718 32.2 6,005 24.0 4,682 15.0 – 5 4,556 21.9 6,398 41.0 5,720 32.0 4,460 21.4 – 6 3,797 15.2 5,332 42.7 4,767 34.3 3,716 23.8 1/4 – 3,588 14.4 5,038 40.3 4,504 32.4 3,511 22.5 5/16 – 2,870 14.9 4,031 32.2 3,603 25.9 2,809 18.0 – 8 2,848 14.8 3,999 35.2 3,575 28.6 2,787 22.3 3/8 – 2,392 13.4 3,359 29.6 3,003 24.0 2,341 18.7 – 10 2,278 14.6 3,199 33.3 2,860 27.5 2,230 19.6 7/16 – 2,050 13.9 2,879 29.9 2,574 24.7 2,007 17.7 – 12 1,899 12.9 2,666 32.0 2,383 25.7 2,101 21.8 1/2 – 1,794 12.2 2,519 30.2 2,252 24.3 1,985 20.6 5/8 – 1,221 12.2 2,015 24.2 1,802 19.5 1,588 16.5 3/4 – 1,018 11.0 1,679 20.2 1,476 15.9 1,349 14.0 1 – 592 6.6 1,260 15.1 1,088 12.2 992 10.3 1. The above milling condition is a guidline for overhang length 3xD. 2. Use a rigid and precise machine and holder. 3. The rotational speed is calculated by the median of the recommended cutting speed. Adjustments may be necessary depending on the rigidity or the workpiece, fixture, and machine. 4. Please use a suitable fluid with high smoke retardant properties. 5. During dry (no fluid) milling, please use air blow to remove chips from the milling area and to eliminate chip packing. 6. Please use water-soluble coolant when machining stainless steel. 7. Reduce speed and feed as well as depth of cut when high precision is required. 8. Adjust the speed and feed accordingly when the overhang length is longer than specified (refer to Parameter Reduction Chart p. 979). WWW.OSGTOOL.COM End Mill Technical 977

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta