Общий каталог OSG 2018 - 2019 - страница 324

Навигация

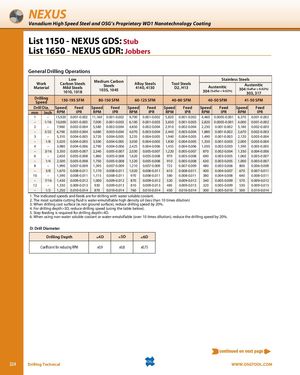

NEXUS Vanadium High Speed Steel and OSG’s Proprietary WD1 Nanotechnology Coating List 1150 - NEXUS GDS: Stub List 1650 - NEXUS GDR: Jobbers General Drilling Operations WorkMaterial LowCarbon SteelsMild Steels1010, 1018Medium CarbonSteels1035, 1045Alloy Steels4140, 4130 Stainless SteelsTool SteelsD2, H13Austenitic304 (Sulfur < 0.02%)Austenitic304 (Sulfur > 0.02%)303, 317 DrillingSpeed 130-195 SFM 80-150 SFM 60-125 SFM 40-80 SFM 40-50 SFM 41-50 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 1 – 15,920 0.001-0.002 11,160 0.001-0.002 9,700 0.001-0.002 5,820 0.001-0.002 4,460 0.0005-0.001 6,370 0.001-0.002 – 1/16 10,000 0.001-0.003 7,000 0.001-0.003 6,100 0.001-0.003 3,650 0.001-0.003 2,820 0.0005-0.001 4,000 0.001-0.002 2 – 7,960 0.002-0.004 5,580 0.002-0.004 4,850 0.002-0.004 2,910 0.002-0.004 2,230 0.001-0.002 3,180 0.002-0.003 – 3/32 6,700 0.003-0.004 4,680 0.003-0.004 4,070 0.003-0.004 2,440 0.003-0.004 1,880 0.001-0.002 2,670 0.002-0.003 3 – 5,310 0.004-0.005 3,720 0.004-0.005 3,235 0.004-0.005 1,940 0.004-0.005 1,490 0.001-0.003 2,120 0.003-0.004 – 1/8 5,020 0.004-0.005 3,500 0.004-0.005 3,050 0.004-0.005 1,830 0.004-0.005 1,350 0.001-0.003 2,000 0.003-0.004 4 – 3,980 0.004-0.006 2,790 0.004-0.006 2,425 0.004-0.006 1,455 0.004-0.006 1,030 0.002-0.003 1,590 0.003-0.005 – 3/16 3,350 0.005-0.007 2,340 0.005-0.007 2,030 0.005-0.007 1,220 0.005-0.007 870 0.002-0.004 1,330 0.004-0.006 6 – 2,650 0.005-0.008 1,860 0.005-0.008 1,620 0.005-0.008 970 0.005-0.008 690 0.003-0.005 1,060 0.005-0.007 – 1/4 2,500 0.005-0.008 1,750 0.005-0.008 1,520 0.005-0.008 910 0.005-0.008 630 0.003-0.005 1,000 0.005-0.007 8 – 1,990 0.007-0.009 1,395 0.007-0.009 1,210 0.007-0.009 725 0.007-0.009 480 0.003-0.006 800 0.006-0.009 – 3/8 1,670 0.008-0.011 1,170 0.008-0.011 1,020 0.008-0.011 610 0.008-0.011 400 0.004-0.007 670 0.007-0.011 10 – 1,590 0.008-0.011 1,115 0.008-0.011 970 0.008-0.011 580 0.008-0.011 380 0.004-0.008 640 0.008-0.011 – 7/16 1,430 0.009-0.012 1,000 0.009-0.012 870 0.009-0.012 520 0.009-0.012 340 0.005-0.009 570 0.009-0.012 12 – 1,330 0.009-0.013 930 0.009-0.013 810 0.009-0.013 485 0.009-0.013 320 0.005-0.009 530 0.009-0.013 – 1/2 1,250 0.010-0.014 870 0.010-0.014 760 0.010-0.014 450 0.010-0.014 300 0.005-0.010 500 0.010-0.014 1. The indicated speeds and feeds are for drilling with water soluble coolant. 2. The most suitable cutting fluid is water-emulsifiable high density oil (less than 10 times dilution) 3. When drilling cast surface (ie.not ground surface), reduce drilling speed by 20%. 4. For drilling depth>3D, reduce drilling speed (using the table below). 5. Step feeding is required for drilling depth>4D. 6. When using non-water soluble coolant or water-emulsifiable (over 10 times dilution), reduce the drilling speed by 20%. D: Drill Diameter Drilling Depth ≤4D ≤5D ≤6D Coefficient for reducing RPM x0.9 x0.8 x0.75 324 Drilling Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta