Общий каталог OSG 2018 - 2019 - страница 322

Навигация

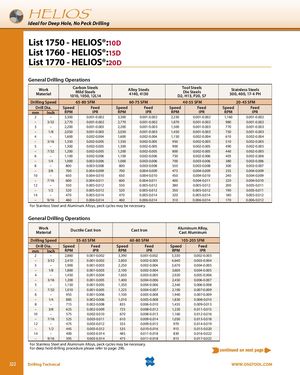

HELIOS ® Ideal for Deep Hole, No Peck Drilling List 1750 - HELIOS®:10D List 1760 - HELIOS®:15D List 1770 - HELIOS®:20D General Drilling Operations WorkMaterial Carbon SteelsMild Steels1010, 1050, 12L14Alloy Steels4140, 4130 Tool SteelsDie SteelsD2, H13, P20, S7Stainless Steels300, 400, 17-4 PH Drilling Speed 65-80 SFM 60-75 SFM 40-55 SFM 20-45 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR 2 – 3,300 0.001-0.002 3,300 0.001-0.002 2,230 0.001-0.002 1,160 0.001-0.002 – 3/32 2,770 0.001-0.002 2,770 0.001-0.002 1,870 0.001-0.002 980 0.001-0.002 3 – 2,200 0.001-0.003 2,200 0.001-0.003 1,500 0.001-0.003 770 0.001-0.003 – 1/8 2,050 0.001-0.003 2,050 0.001-0.003 1,450 0.001-0.003 750 0.001-0.003 4 – 1,600 0.002-0.004 1,600 0.002-0.004 1,150 0.002-0.004 610 0.002-0.004 – 3/16 1,350 0.002-0.005 1,350 0.002-0.005 950 0.002-0.005 510 0.002-0.005 5 – 1,300 0.002-0.005 1,300 0.002-0.005 900 0.002-0.005 490 0.002-0.005 – 7/32 1,200 0.002-0.005 1,200 0.002-0.005 800 0.002-0.005 440 0.002-0.005 6 – 1,100 0.002-0.006 1,100 0.002-0.006 750 0.002-0.006 405 0.002-0.006 – 1/4 1,000 0.003-0.006 1,000 0.003-0.006 700 0.003-0.006 380 0.003-0.006 8 – 800 0.003-0.008 800 0.003-0.008 550 0.003-0.008 300 0.003-0.007 – 3/8 700 0.004-0.009 700 0.004-0.009 475 0.004-0.009 255 0.004-0.009 10 – 650 0.004-0.010 650 0.004-0.010 450 0.004-0.010 240 0.004-0.009 – 7/16 600 0.004-0.011 600 0.004-0.011 400 0.004-0.011 220 0.004-0.010 12 – 550 0.005-0.012 550 0.005-0.012 380 0.005-0.012 200 0.005-0.011 – 1/2 520 0.005-0.012 520 0.005-0.012 350 0.005-0.012 190 0.005-0.011 14 – 470 0.005-0.014 470 0.005-0.014 320 0.005-0.014 180 0.005-0.012 – 9/16 460 0.006-0.014 460 0.006-0.014 310 0.006-0.014 170 0.006-0.012 For Stainless Steel and Aluminum Alloys, peck cycles may be necessary. General Drilling Operations WorkMaterial Ductile Cast Iron Cast Iron Aluminum Alloy,Cast Aluminum Drilling Speed 55-65 SFM 60-80 SFM 105-205 SFM Drill Dia. Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR 2 – 2,860 0.001-0.002 3,390 0.001-0.002 5,530 0.002-0.003 – 3/32 2,410 0.001-0.002 2,850 0.002-0.003 4,640 0.003-0.004 3 – 1,900 0.001-0.003 2,250 0.002-0.004 3,670 0.004-0.005 – 1/8 1,800 0.001-0.003 2,100 0.002-0.004 3,600 0.004-0.005 4 – 1,450 0.001-0.004 1,650 0.003-0.005 2,920 0.005-0.006 – 3/16 1,200 0.001-0.005 1,400 0.004-0.006 2,450 0.006-0.007 5 – 1,150 0.001-0.005 1,350 0.004-0.006 2,340 0.006-0.008 – 7/32 1,010 0.001-0.005 1,225 0.004-0.007 2,100 0.007-0.009 6 – 955 0.001-0.006 1,100 0.005-0.008 1,940 0.007-0.009 – 1/4 885 0.002-0.006 1,010 0.005-0.008 1,830 0.008-0.010 8 – 715 0.002-0.008 835 0.006-0.010 1,455 0.009-0.013 – 3/8 625 0.002-0.009 725 0.008-0.012 1,220 0.011-0.015 10 – 575 0.002-0.010 670 0.008-0.013 1,160 0.012-0.016 – 7/16 525 0.003-0.011 610 0.009-0.014 1,050 0.013-0.018 12 – 475 0.003-0.012 555 0.009-0.015 970 0.014-0.019 – 1/2 445 0.003-0.012 535 0.010-0.016 915 0.015-0.020 14 – 400 0.003-0.014 485 0.011-0.018 830 0.016-0.022 – 9/16 395 0.003-0.014 475 0.011-0.018 815 0.017-0.022 For Stainless Steel and Aluminum Alloys, peck cycles may be necessary. For deep hold drilling procedure please refer to page: 296. 322 Drilling Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta