Общий каталог OSG 2018 - 2019 - страница 320

Навигация

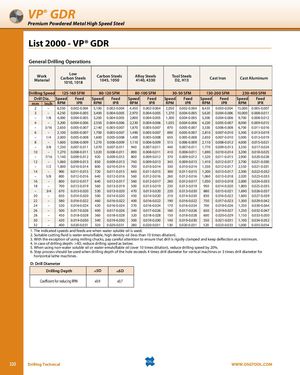

VP® GDR Premium Powdered Metal High Speed Steel List 2000 - VP® GDR General Drilling Operations WorkMaterial LowCarbon Steels1010, 1018Carbon Steels1045, 1050Alloy Steels4140, 4330Tool SteelsD2, H13 Cast Iron Cast Aluminum Drilling Speed 125-160 SFM 80-120 SFM 80-100 SFM 30-50 SFM 130-200 SFM 230-400 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 2 – 6,350 0.002-0.004 5,100 0.002-0.004 4,450 0.002-0.004 2,050 0.002-0.004 8,435 0.003-0.004 15,000 0.005-0.007 3 – 4,250 0.004-0.005 3,400 0.004-0.005 2,970 0.004-0.005 1,370 0.004-0.005 5,620 0.004-0.006 10,000 0.008-0.011 – 1/8 4,000 0.004-0.005 3,200 0.004-0.005 2,800 0.004-0.005 1,300 0.004-0.005 5,300 0.004-0.006 9,700 0.008-0.012 4 – 3,200 0.004-0.006 2,550 0.004-0.006 2,230 0.004-0.006 1,035 0.004-0.006 4,220 0.005-0.007 8,000 0.009-0.015 – 3/16 2,650 0.005-0.007 2,140 0.005-0.007 1,870 0.005-0.007 870 0.005-0.007 3,530 0.006-0.008 6,700 0.011-0.016 6 – 2,100 0.005-0.007 1,700 0.005-0.007 1,490 0.005-0.007 690 0.005-0.007 2,810 0.007-0.010 5,300 0.013-0.019 – 1/4 2,000 0.005-0.008 1,600 0.005-0.008 1,400 0.005-0.008 650 0.005-0.008 2,650 0.007-0.010 5,000 0.013-0.019 8 – 1,600 0.006-0.009 1,270 0.006-0.009 1,110 0.006-0.009 515 0.006-0.009 2,110 0.008-0.012 4,000 0.015-0.021 – 3/8 1,330 0.007-0.011 1,070 0.007-0.011 940 0.007-0.011 440 0.007-0.011 1,770 0.009-0.013 3,350 0.017-0.024 10 – 1,270 0.008-0.011 1,020 0.008-0.011 890 0.008-0.011 410 0.008-0.011 1,690 0.010-0.014 3,200 0.018-0.025 – 7/16 1,140 0.009-0.012 920 0.009-0.012 800 0.009-0.012 370 0.009-0.012 1,520 0.011-0.015 2,900 0.020-0.028 12 – 1,060 0.009-0.013 850 0.009-0.013 740 0.009-0.013 345 0.009-0.013 1,410 0.012-0.017 2,700 0.021-0.030 – 1/2 1,000 0.010-0.014 800 0.010-0.014 700 0.010-0.014 330 0.010-0.014 1,330 0.012-0.017 2,550 0.021-0.031 14 – 900 0.011-0.015 720 0.011-0.015 640 0.011-0.015 300 0.011-0.015 1,200 0.013-0.017 2,300 0.022-0.032 – 5/8 800 0.012-0.016 640 0.012-0.016 560 0.012-0.016 260 0.012-0.016 1,060 0.013-0.018 2,020 0.023-0.033 16 – 800 0.012-0.017 640 0.012-0.017 560 0.012-0.017 260 0.012-0.017 1,050 0.013-0.018 2,000 0.024-0.033 18 – 700 0.013-0.019 560 0.013-0.019 500 0.013-0.019 230 0.013-0.019 950 0.014-0.020 1,800 0.025-0.035 – 3/4 670 0.013-0.020 530 0.013-0.020 470 0.013-0.020 220 0.013-0.020 880 0.015-0.021 1,690 0.026-0.037 20 – 650 0.014-0.020 500 0.014-0.020 450 0.014-0.020 210 0.014-0.020 830 0.016-0.022 1,600 0.027-0.039 22 – 580 0.016-0.022 460 0.016-0.022 400 0.016-0.022 190 0.016-0.022 750 0.017-0.023 1,500 0.029-0.042 24 – 530 0.016-0.024 420 0.016-0.024 370 0.016-0.024 170 0.016-0.024 700 0.018-0.026 1,350 0.030-0.044 26 – 500 0.017-0.026 400 0.017-0.026 340 0.017-0.026 160 0.017-0.026 650 0.019-0.027 1,250 0.032-0.047 28 – 450 0.018-0.028 360 0.018-0.028 320 0.018-0.028 150 0.018-0.028 600 0.020-0.029 1,150 0.033-0.050 30 – 420 0.019-0.030 340 0.019-0.030 300 0.019-0.030 140 0.019-0.030 550 0.021-0.031 1,100 0.034-0.052 32 – 400 0.020-0.031 320 0.020-0.031 280 0.020-0.031 130 0.020-0.031 520 0.023-0.033 1,000 0.035-0.054 1. The indicated speeds and feeds are when water soluble oil is used. 2. Suitable cutting fluid is water-emulsifiable, high density oil (less than 10 times dilution). 3. With the exception of using milling chucks, pay careful attention to ensure that drill is rigidly clamped and keep deflection at a minimum. 4. In case of drilling depth: >4D, reduce drilling speed as below. 5. When using non-water soluble oil or water-emulsifiable oil (over 10 times dilution), reduce drilling speed by 20%. 6. Step process should be used when drilling depth of the hole exceeds 4 times drill diameter for vertical machines or 3 times drill diameter for horizontal lathe machines. D: Drill Diameter Drilling Depth ≤5D ≤6D Coefficient for reducing RPM x0.9 x0.7 320 Drilling Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta