Общий каталог OSG 2018 - 2019 - страница 316

Навигация

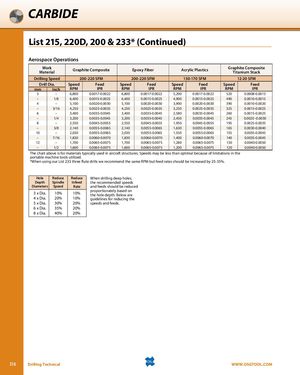

CARBIDE List 215, 220D, 200 & 233* (Continued) Aerospace Operations WorkMaterial Graphite Composite Epoxy Fiber Acrylic Plastics Graphite CompositeTitanium Stack Drilling Speed 200-220 SFM 200-220 SFM 150-170 SFM 12-20 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR 3 – 6,800 0.0017-0.0022 6,800 0.0017-0.0022 5,200 0.0017-0.0022 520 0.0008-0.0013 – 1/8 6,400 0.0015-0.0025 6,400 0.0015-0.0025 4,900 0.0015-0.0025 490 0.0010-0.0015 4 – 5,100 0.0020-0.0030 5,100 0.0020-0.0030 3,900 0.0020-0.0030 390 0.0010-0.0020 – 3/16 4,250 0.0025-0.0035 4,250 0.0025-0.0035 3,250 0.0025-0.0035 325 0.0015-0.0025 6 – 3,400 0.0035-0.0045 3,400 0.0035-0.0045 2,580 0.0035-0.0045 260 0.0015-0.0025 – 1/4 3,200 0.0035-0.0045 3,200 0.0035-0.0045 2,450 0.0035-0.0045 245 0.0020 -0.0030 8 – 2,550 0.0045-0.0055 2,550 0.0045-0.0055 1,950 0.0045-0.0055 195 0.0025-0.0035 – 3/8 2,140 0.0055-0.0065 2,140 0.0055-0.0065 1,630 0.0055-0.0065 165 0.0030-0.0040 10 – 2,030 0.0055-0.0065 2,030 0.0055-0.0065 1,550 0.0055-0.0065 155 0.0035-0.0045 – 7/16 1,830 0.0060-0.0070 1,830 0.0060-0.0070 1,400 0.0060-0.0070 140 0.0035-0.0045 12 – 1,700 0.0065-0.0075 1,700 0.0065-0.0075 1,280 0.0065-0.0075 130 0.0040-0.0050 – 1/2 1,600 0.0065-0.0075 1,600 0.0065-0.0075 1,200 0.0065-0.0075 120 0.0040-0.0050 The chart above is for materials typically used in aircraft structures. Speeds may be less than optimal because of limitations in the portable machine tools utilized. *When using our List 233 three flute drills we recommend the same RPM but feed rates should be increased by 25-35%. Hole Reduce Reduce When drilling deep holes, Depth Spindle Infeed the recommended speeds Diameters Speed Rate and feeds should be reduced 3 x Dia. 10% 10% proportionately based onthe hole depth. Below are 4 x Dia. 20% 10% guidelines for reducing the 5 x Dia. 30% 20% speeds and feeds. 6 x Dia. 35% 20% 8 x Dia. 40% 20% 316 Drilling Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta