Общий каталог OSG 2018 - 2019 - страница 310

Навигация

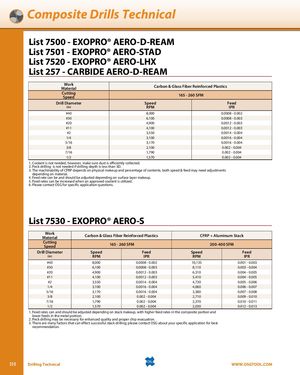

Composite Drills Technical List 7500 - EXOPRO® AERO-D-REAM List 7501 - EXOPRO® AERO-STAD List 7520 - EXOPRO® AERO-LHX List 257 - CARBIDE AERO-D-REAM WorkMaterial Carbon & Glass Fiber Reinforced Plastics CuttingSpeed 165 - 260 SFM Drill Diameter Speed Feed (in) RPM IPR #40 8,000 0.0008 - 0.002 #30 6,100 0.0008 - 0.003 #20 4,900 0.0012 - 0.003 #11 4,100 0.0012 - 0.003 #2 3,550 0.0014 - 0.004 1/4 3,100 0.0016 - 0.004 5/16 3,170 0.0016 - 0.004 3/8 2,100 0.002 - 0.004 7/16 1,790 0.002 - 0.004 1/2 1,570 0.002 - 0.004 1. Coolant is not needed, however, make sure dust is efficiently collected. 2. Peck drilling is not needed if drilling depth is less than 3D. 3. The machinability of CFRP depends on physical makeup and percentage of contents, both speed & feed may need adjustments depending on material. 4. Feed rate can be and should be adjusted depending on surface layer makeup. 5. Feed rates can be increased when an approved coolant is utilized. 6. Please contact OSG for specific application questions. List 7530 - EXOPRO® AERO-S WorkMaterial Carbon & Glass Fiber Reinforced Plastics CFRP + Aluminum Stack CuttingSpeed 165 - 260 SFM 200-400 SFM Drill Diameter Speed Feed Speed Feed (in) RPM IPR RPM IPR #40 8,000 0.0008 - 0.002 10,135 0.001 - 0.003 #30 6,100 0.0008 - 0.003 8,110 0.003 - 0.004 #20 4,900 0.0012 - 0.003 6,310 0.004 - 0.005 #11 4,100 0.0012 - 0.003 5,410 0.004 - 0.005 #2 3,550 0.0014 - 0.004 4,730 0.005 - 0.006 1/4 3,100 0.0016 - 0.004 4,060 0.006 - 0.007 5/16 3,170 0.0016 - 0.004 3,380 0.007 - 0.008 3/8 2,100 0.002 - 0.004 2,710 0.009 - 0.010 7/16 1,790 0.002 - 0.004 2,370 0.010 - 0.011 1/2 1,570 0.002 - 0.004 2,030 0.012 - 0.013 1. Feed rates can and should be adjusted depending on stack makeup, with higher feed rates in the composite portion and lower feeds in the metal portion. 2. Peck drilling may be necessary for enhanced quality and proper chip evacuation. 3. There are many factors that can effect successful stack drilling; please contact OSG about your specific application for best recommendation. 310 Drilling Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta