Общий каталог OSG 2018 - 2019 - страница 309

Навигация

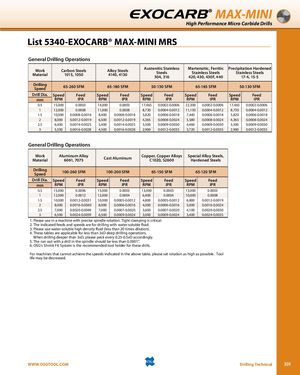

EXOCARB® MAX-MINI High Performance Micro Carbide Drills List 5340-EXOCARB® MAX-MINI MRS General Drilling Operations Work Carbon SteelsMaterial1015, 1050Alloy Steels4140, 4130 Austenitic Stainless Martensitic, Ferritic Precipitation HardenedSteelsStainless SteelsStainless Steels304, 316420, 430, 430F, 44017-4, 15-5 DrillingSpeed 65-260 SFM 65-180 SFM 50-130 SFM 65-165 SFM 50-130 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 0.5 15,000 0.0003 14,000 0.0003 17,465 0.0002-0.0006 22,300 0.0002-0.0006 17,465 0.0002-0.0006 1 12,000 0.0008 11,000 0.0008 8,730 0.0004-0.0012 11,150 0.0004-0.0012 8,730 0.0004-0.0012 1.5 10,000 0.0008-0.0016 8,400 0.0008-0.0016 5,820 0.0006-0.0018 7,440 0.0006-0.0018 5,820 0.0006-0.0018 2 8,000 0.0012-0.0019 6,500 0.0012-0.0019 4,365 0.0008-0.0024 5,580 0.0008-0.0024 4,365 0.0008-0.0024 2.5 6,400 0.0014-0.0025 5,400 0.0014-0.0025 3,500 0.0009-0.0030 4,460 0.0009-0.0030 3,500 0.0009-0.0030 3 5,500 0.0016-0.0028 4,500 0.0016-0.0028 2,900 0.0012-0.0035 3,720 0.0012-0.0035 2,900 0.0012-0.0035 General Drilling Operations Work Aluminum AlloyMaterial6061, 7075Cast Aluminum Copper, Copper Alloys Special Alloy Steels,C1020, S2600Hardened Steels DrillingSpeed 100-260 SFM 100-200 SFM 65-150 SFM 65-120 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed mm RPM IPR RPM IPR RPM IPR RPM IPR 0.5 15,000 0.0006 15,000 0.0003 13,000 0.0003 13,000 0.0003 1 12,000 0.0012 12,000 0.0004 6,400 0.0004 10,000 0.0008 1.5 10,000 0.0012-0.0031 10,000 0.0005-0.0012 4,800 0.0005-0.0012 6,800 0.0012-0.0019 2 8,000 0.0016-0.0040 8,000 0.0006-0.0016 4,000 0.0006-0.0016 5,000 0.0016-0.0024 2.5 7,000 0.0020-0.0049 7,000 0.0007-0.0020 3,600 0.0007-0.0020 4,100 0.0020-0.0030 3 6,500 0.0024-0.0059 6,500 0.0009-0.0024 3,000 0.0009-0.0024 3,400 0.0024-0.0035 1. Please use in a machine with precise spindle rotation. Tight clamping is critical. 2. The indicated feeds and speeds are for drilling with water-soluble fluid. 3. Please use water-soluble high density fluid (less than 20 times dilution). 4. These tables are applicable for less than 3xD deep drilling operations. When drilling deeper than 3xD, please peck every 0.25-0.5xD accordingly. 5. The run out with a drill in the spindle should be less than 0.0001”. 6. OSG’s Shrink Fit System is the recommended tool holder for these drills. For machines that cannot achieve the speeds indicated in the above table, please set rotation as high as possible. Tool life may be decreased. WWW.OSGTOOL.COM Drilling Technical 309

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta