Общий каталог OSG 2018 - 2019 - страница 292

Навигация

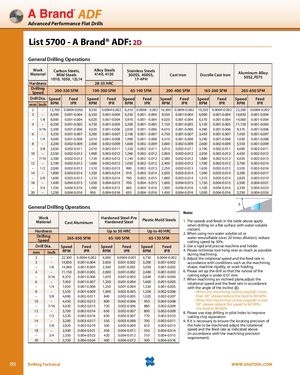

ADF Advanced Performance Flat Drills List 5700 - A Brand® ADF: 2D General Drilling Operations Work Carbon Steels, Alloy Steels Stainless SteelsMaterialMild Steels4140, 4130300SS, 400SS,1010, 1050, 12L1417-4PHCast IronDuctile Cast IronAluminum Alloy5052,7075 Hardness 28-35 HRC DrillingSpeed 200-330 SFM 100-300 SFM 65-140 SFM 200-400 SFM 165-260 SFM 265-650 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 2 – 12,700 0.0004-0.002 9,550 0.0004-0.002 6,310 0.0004 - 0.002 14,300 0.0004-0.002 10,350 0.0004-0.002 22,300 0.0004-0.002 3 – 8,500 0.001-0.004 6,350 0.001-0.004 4,250 0.001 - 0.004 9,550 0.001-0.004 6,900 0.001-0.004 14,850 0.001-0.004 – 1/8 8,000 0.001-0.004 6,020 0.001-0.004 3,970 0.001 - 0.004 9,020 0.001-0.004 6,570 0.001-0.004 14,060 0.001-0.004 4 – 6,350 0.001-0.005 4,750 0.001-0.005 3,200 0.001 - 0.005 7,150 0.001-0.005 5,150 0.001-0.005 11,150 0.001-0.005 – 3/16 5,300 0.001-0.006 4,020 0.001-0.006 2,650 0.001 - 0.006 6,010 0.001-0.006 4,380 0.001-0.006 9,370 0.001-0.006 6 – 4,250 0.001-0.007 3,200 0.001-0.007 2,100 0.001 - 0.007 4,750 0.001-0.007 3,450 0.001-0.007 7,450 0.001-0.007 – 1/4 4,000 0.001-0.008 3,010 0.001-0.008 1,990 0.001 - 0.008 4,510 0.001-0.008 3,290 0.001-0.008 7,030 0.001-0.008 8 – 3,200 0.002-0.009 2,400 0.002-0.009 1,600 0.002 - 0.009 3,600 0.002-0.009 2,600 0.002-0.009 5,550 0.001-0.009 – 3/8 2,650 0.002-0.011 2,010 0.002-0.011 1,320 0.002 - 0.011 3,010 0.002-0.011 2,190 0.002-0.011 4,690 0.002-0.011 10 – 2,550 0.002-0.012 1,900 0.002-0.012 1,260 0.002 - 0.012 2,850 0.002-0.012 2,050 0.002-0.012 4,450 0.002-0.012 – 7/16 2,300 0.002-0.012 1,720 0.002-0.012 1,140 0.002 - 0.012 2,580 0.002-0.012 1,880 0.002-0.012 4,020 0.002-0.013 12 – 2,100 0.002-0.012 1,600 0.002-0.012 1,050 0.002 - 0.012 2,400 0.002-0.012 1,700 0.002-0.012 3,700 0.002-0.014 – 1/2 2,000 0.002-0.013 1,510 0.002-0.013 990 0.002 - 0.013 2,250 0.002-0.013 1,650 0.002-0.013 3,520 0.002-0.016 14 – 1,800 0.003-0.014 1,350 0.003-0.014 910 0.003 - 0.014 2,050 0.003-0.014 1,500 0.003-0.014 3,200 0.003-0.017 – 5/8 1,600 0.003-0.015 1,210 0.003-0.014 790 0.003 - 0.015 1,800 0.003-0.014 1,310 0.003-0.014 2,820 0.003-0.019 18 – 1,400 0.004-0.015 1,050 0.004-0.015 700 0.004 - 0.015 1,600 0.004-0.015 1,150 0.004-0.015 2,500 0.004-0.021 – 3/4 1,350 0.004-0.016 1,000 0.004-0.015 660 0.004 - 0.016 1,500 0.004-0.016 1,100 0.004-0.016 2,350 0.004-0.023 20 – 1,250 0.004-0.016 950 0.004-0.016 635 0.004 - 0.016 1,450 0.004-0.016 1,050 0.004-0.016 2,250 0.004-0.024 General Drilling Operations β Note: WorkMaterial Cast Aluminum Hardened Steel-PreHardened SteelPlastic Mold Steels 1. The speeds and feeds in the table above applywhen drilling on a flat surface with water-soluble HardnessDrillingSpeed265-650 SFM Up to 50 HRC65-100 SFM Up to 40 HRC coolant.2. When using non-water soluble oil or65-130 SFMwater-emulsifiable (over 20 times dilution), reducecutting speed by 30%. Drill Dia. Speed Feed Speed Feed Speed Feed 3. Use a rigid and precise machine and holder. mm Inch RPM IPR RPM IPR RPM IPR 4. Please minimize tool hang over as much as possibleduring machining. 2 – 22,300 0.0004-0.002 4,000 0.0004-0.001 4,750 0.0004-0.002 5. Adjust the rotational speed and the feed rate in 3 – 14,850 0.001-0.004 2,650 0.001-0.002 3,200 0.001-0.002 accordance with conditions such as the machining – 1/8 14,060 0.001-0.004 2,500 0.001-0.002 3,050 0.001-0.002 shape, machine rigidity, or work holding. 4 – 11,150 0.001-0.005 2,000 0.001-0.002 2,400 0.001-0.003 6. Please set up the drill so that the runout of the –6 3/16– 9,3707,4500.001-0.0060.001-0.0071,6701,3500.001-0.0030.001-0.0042,0401,6000.001-0.0040.001-0.005cutting edge is under 0.01 mm.7. When machining an inclined plane,adjust therotational speed and the feed rate in accordance – 1/4 7,030 0.001-0.008 1,250 0.001-0.004 1,530 0.001-0.005 with the angle of the incline (β). 8 – 5,550 0.001-0.009 1,000 0.002-0.005 1,200 0.002-0.006 • When the machining incline angle(β) is less – 3/8 4,690 0.002-0.011 840 0.002-0.005 1,020 0.002-0.007 than 30°, please reduce the feed to 40-60%. 10 – 4,450 0.002-0.012 800 0.002-0.006 950 0.002-0.008 • When the machining incline angle(β) is over – 7/16 4,020 0.002-0.013 720 0.002-0.006 880 0.002-0.009 30°, please reduce the speed to 60-80% ,the feed to 40-60%. 12 – 3,700 0.002-0.014 650 0.002-0.007 800 0.002-0.009 8. Please use step drilling in pilot holes to improve – 1/2 3,520 0.002-0.016 630 0.002-0.007 770 0.002-0.010 cutting chip separation. 14 – 3,200 0.003-0.017 550 0.003-0.008 700 0.003-0.011 9. If it is necessary to ensure the locating precision of – 5/8 2,820 0.003-0.019 500 0.003-0.009 610 0.003-0.013 the hole to be machined, adjust the rotational 18 – 2,500 0.004-0.021 450 0.004-0.011 550 0.004-0.014 speed and the feed rate as indicated above – 3/4 2,350 0.004-0.023 420 0.004-0.012 510 0.004-0.015 (in accordance with the machining precisionrequirement). 20 – 2,250 0.004-0.024 400 0.004-0.012 500 0.004-0.016 292 Drilling Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta