Общий каталог OSG 2018 - 2019 - страница 291

Навигация

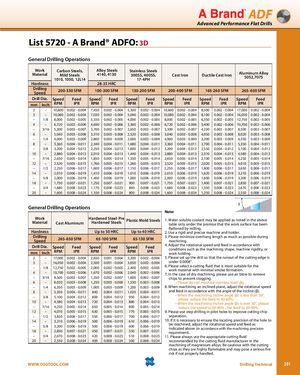

ADF Advanced Performance Flat Drills List 5720 - A Brand® ADFO: 3D General Drilling Operations Work Carbon Steels, Alloy Steels Stainless SteelsMaterialMild Steels4140, 4130300SS, 400SS,1010, 1050, 12L1417-4PHCast IronDuctile Cast IronAluminum Alloy5052,7075 Hardness 28-35 HRC DrillingSpeed 200-330 SFM 100-300 SFM 130-200 SFM 200-400 SFM 165-260 SFM 265-650 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 2 – 10,600 0.002 - 0.004 7,450 0.002 - 0.004 5,300 0.002 - 0.004 10,600 0.002 - 0.004 8,500 0.002 - 0.004 17,000 0.002 - 0.004 3 – 10,080 0.002 - 0.004 7,030 0.002 - 0.004 5,040 0.002 - 0.004 10,080 0.002 - 0.004 8,100 0.002 - 0.004 16,050 0.002 - 0.004 – 1/8 8,000 0.002 - 0.005 5,550 0.002 - 0.005 4,000 0.002 - 0.005 8,000 0.002 - 0.005 6,350 0.002 - 0.005 12,750 0.002 - 0.005 4 – 6,720 0.002 - 0.006 4,690 0.002 - 0.006 3,360 0.002 - 0.006 6,720 0.002 - 0.006 5,400 0.002 - 0.006 10,700 0.002 - 0.006 – 3/16 5,300 0.002 - 0.007 3,700 0.002 - 0.007 2,650 0.002 - 0.007 5,300 0.002 - 0.007 4,250 0.002 - 0.007 8,500 0.002 - 0.007 6 – 5,040 0.003 - 0.008 3,510 0.003 - 0.008 2,520 0.003 - 0.008 5,040 0.003 - 0.008 4,050 0.003 - 0.008 8,020 0.003 - 0.008 – 1/4 4,000 0.003 - 0.009 2,800 0.003 - 0.009 2,000 0.003 - 0.009 4,000 0.003 - 0.009 3,200 0.003 - 0.009 6,350 0.003 - 0.009 8 – 3,360 0.004 - 0.011 2,340 0.004 - 0.011 1,680 0.004 - 0.011 3,360 0.004 - 0.011 2,700 0.004 - 0.011 5,350 0.004 - 0.011 – 3/8 3,200 0.004 - 0.012 2,250 0.004 - 0.012 1,600 0.004 - 0.012 3,200 0.004 - 0.012 2,550 0.004 - 0.012 5,100 0.004 - 0.012 10 – 2,880 0.004 - 0.013 2,010 0.004 - 0.013 1,440 0.004 - 0.013 2,880 0.004 - 0.013 2,310 0.004 - 0.013 4,580 0.004 - 0.013 – 7/16 2,650 0.005 - 0.014 1,850 0.005 - 0.014 1,350 0.005 - 0.014 2,650 0.005 - 0.014 2,100 0.005 - 0.014 4,250 0.005 - 0.014 12 – 2,520 0.005 - 0.015 1,760 0.005 - 0.015 1,260 0.005 - 0.015 2,520 0.005 - 0.015 2,020 0.005 - 0.015 4,010 0.005 - 0.015 – 1/2 2,250 0.006 - 0.017 1,600 0.006 - 0.017 1,150 0.006 - 0.017 2,250 0.006 - 0.017 1,800 0.006 - 0.017 3,650 0.006 - 0.017 14 – 2,010 0.006 - 0.019 1,410 0.006 - 0.019 1,010 0.006 - 0.019 2,010 0.006 - 0.019 1,620 0.006 - 0.019 3,210 0.006 - 0.019 – 5/8 2,000 0.006 - 0.019 1,400 0.006 - 0.019 1,000 0.006 - 0.019 2,000 0.006 - 0.019 1,600 0.006 - 0.019 3,200 0.006 - 0.019 18 – 1,750 0.007 - 0.021 1,250 0.007 - 0.021 900 0.007 - 0.021 1,750 0.007 - 0.021 1,400 0.007 - 0.021 2,850 0.007 - 0.021 – 3/4 1,680 0.008 - 0.023 1,170 0.008 - 0.023 840 0.008 - 0.023 1,680 0.008 - 0.023 1,350 0.008 - 0.023 2,670 0.008 - 0.023 20 – 1,600 0.008 - 0.024 1,100 0.008 - 0.024 800 0.008 - 0.024 1,600 0.008 - 0.024 1,250 0.008 - 0.024 2,550 0.008 - 0.024 β General Drilling Operations Note: WorkMaterialCast Aluminum Hardened Steel-Pre Hardened Steels Plastic Mold Steels 1. Water-soluble coolant may be applied as noted in the abovetable only under the premise that the work surface has been flattened by milling. Hardness Up to 50 HRC Up to 40 HRC 2. Use a rigid and precise machine and holder. DrillingSpeed 265-650 SFM 65-100 SFM 65-130 SFM 3. Please minimize overhang length as much as possible duringmachining. Drill Dia. Speed Feed Speed Feed Speed FeedmmInchRPMIPRRPMIPRRPMIPR4. Adjust the rotational speed and feed in accordance withconditions such as the machining shape, machine rigidity, orwork holding. 2 – 17,000 0.002 - 0.004 2,650 0.001 - 0.004 3,200 0.002 - 0.004 5. Please set up the drill so that the runout of the cutting edge is 3 – 16,050 0.002 - 0.004 2,500 0.001 - 0.004 3,050 0.002 - 0.004 under 0.0008”. –4 1/8– 12,750 0.002 - 0.00510,7000.002 - 0.0062,0001,6700.002 - 0.0050.002 - 0.0062,4002,0400.002 - 0.0050.002 - 0.0066. Please select a cutting fluid that is most suitable for thework material with minimal smoke formation.7. In the case of dry machining, please use air blow to remove – 3/16 8,500 0.002 - 0.007 1,350 0.002 - 0.007 1,600 0.002 - 0.007 chips to prevent clogging. 6 – 8,020 0.003 - 0.008 1,250 0.003 - 0.008 1,530 0.003 - 0.008 • Please do not machine stainless steel dry. – 1/4 6,350 0.003 - 0.009 1,000 0.003 - 0.009 1,200 0.003 - 0.009 8. When machining an inclined plane, adjust the rotational speed 8 – 5,350 0.004 - 0.011 840 0.004 - 0.011 1,020 0.004 - 0.011 and feed in accordance with the angle of the incline (β). –10 3/8– 5,100 0.004 - 0.0124,5800.004 - 0.0138007200.004 - 0.0120.004 - 0.0139508800.004 - 0.0120.004 - 0.013 • When the machining incline angle (β) is less than 30°,please reduce the feed to 40-60%.• When the machining incline angle (β) is over 30°, please – 7/16 4,250 0.005 - 0.014 650 0.005 - 0.014 800 0.005 - 0.014 reduce the speed to 60-80% , the feed to 20-40%. 12 – 4,010 0.005 - 0.015 630 0.005 - 0.015 770 0.005 - 0.015 9. Please use step drilling in pilot holes to improve cutting chip – 1/2 3,650 0.006 - 0.017 550 0.006 - 0.017 700 0.006 - 0.017 separation. 14 – 3,210 0.006 - 0.019 500 0.006 - 0.019 610 0.006 - 0.019 10. If it is necessary to ensure the locating precision of the hole to – 5/8 3,200 0.006 - 0.019 500 0.006 - 0.019 600 0.006 - 0.019 be machined, adjust the rotational speed and feed asindicated above (in accordance with the machining precision 18 – 2,850 0.007 - 0.021 450 0.007 - 0.021 550 0.007 - 0.021 requirement). – 3/4 2,670 0.008 - 0.023 420 0.008 - 0.023 510 0.008 - 0.023 11. Please always use the appropriate cutting fluid 20 – 2,550 0.008 - 0.024 400 0.008 - 0.024 500 0.008 - 0.024 recommended by the cutting fluid manufacturer in the machining of magnesium alloys. Be cautious with the cutting chips as they are highly flammable and may pose a serious fire risk if not properly handled. WWW.OSGTOOL.COM Drilling Technical 291

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta